PLASTIC RESIN

What is plastic resin?

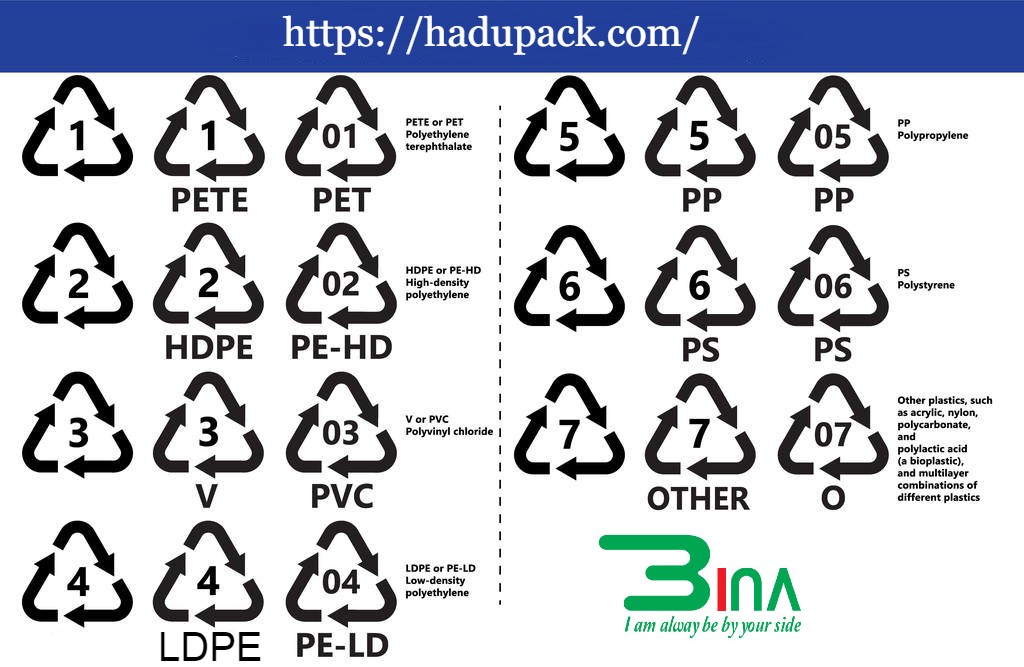

Masterbatch is a small granule used as the main raw material to make plastic products. To produce a plastic product, people will mix the base resin with other ingredients (color beads, filler CaCo3, plastic additives…) to create the desired final product. Normally, plastic beads are divided based on 2 criteria:

Classification based on origin: fossil plastic and bioplastic. Sort by used/unused: primary plastic (derived from fossils) and recycled plastic (recycled from virgin plastic).

☞See more: Plastic strapping

Primary plastic beads (fossil resins)

Primary plastic beads are plastic made from petroleum, without any impurities or additives. Therefore, the color of primary plastic is usually white. If you want to produce products from colored primary plastic, users need to mix more pigments or other color particles according to the formula to get the desired color.

Currently, commonly used primary plastics can be mentioned as ABS, PP, PC, PS-GPPS, PA, HIPS, POM, PMMA, etc. These plastics will be used according to the following formulas: Different ratios to meet specific requirements of finished products. The characteristics of primary plastic are flexibility and high elasticity, good warping resistance. The surface of the product made from primary plastic is usually glossy, smooth, and bright in color.

Recycled plastic resin

You may have somewhat guessed it when you heard the name of this plastic. Recycled plastic beads are quite popular plastic beads today. It is produced from old plastic waste collected, such as bottles, old household appliances, waste machinery, etc. To create recycled plastic, people need to go through steps that include sorting, crushing, cleaning, drying, and melting. The final product will be plastic fibers or plastic particles. So according to the above explanation, recycled plastic beads are the recycling of primary plastic beads, so whatever types of virgin plastic beads are, the recycled plastic beads also have that type of plastic.

Because it is a recycled plastic, the performance of this plastic will be reduced when compared to virgin plastic.

Bioplastics

Unlike the two types of plastic mentioned above, bioplastics are made from natural materials such as starch, protein, and cellulose. The advantage of bioplastics is that most of them are biodegradable and do not pollute the environment. Currently, bioplastics are used to produce utensils that come in contact with food such as trays, spoons, forks, straws, packaging, plastic bags, water bottles, etc.

Applications of plastic beads

a. Applications of pp plastic : Recycled PP plastic granules are used to weave cement bags, animal feed bags, food bags, mineral bags, etc. In addition, PP plastic is also classified into: PP plastic film coated and PP blown. In which, when coated with PP film, it is necessary to avoid contact with the air and avoid moisture; and PP plastic pellets blown into nylon requires hardness and withstands heavy objects contained in it.

b. Application of HDPE plastic pellets: This plastic pellet includes 3 main types including:

- + HDPE injection molding: used for pressing beer kegs, pressing cork, pressing household appliances.

- + HDPR blowing: used to blow up plastic bags.

- + Dry HDPR, extrusion: used for blowing cans, blowing cosmetic bottles, extruding pipes in the electricity and telecommunications industry containing cables and wires buried underground.

c. Application of LDPE resin: This resin is also used in many fields, but mainly for blowing bags, pressing some details or making foam.

d.Application of LLDPE

Applied in a number of key areas such as:

- + LLDPR blow bag, blow film: used for blowing plastic bags, blowing agricultural mulch.

- + LLDPE used in power cables.

- + LLDPE for pressing water tanks: this material helps to replace water tanks with other materials

e. ABS plastic beads: This type of plastic beads is mainly used in injection molding technology. Besides, ABS resin can also be used to make other equipment such as: parts in motorcycles, battery shells, helmets, water heaters, car parts, and other parts. details in electronic machinery…

f. Hips plastic beads: HIPS plastic beads are mainly used in the molding and laminating industry. In fact, HIPS plastic beads are used to press tables and chairs for students, press details in motorcycles, in food technology, etc.

g. GPPS plastic beads: This type is mainly used for processing in injection molding technology with many different applications such as: propeller blades, wall clock faces, candy box trays, …

H. Pet plastic beads: PET plastic beads are applied in two main fields: bottle blowing and laminating in the food industry.

i. PVC granules: PVC granules have 2 main types: hard PVC and soft PVC. Specifically:

- + Rigid PVC: used to extrude water pipes and many other outdoor details.

- + Soft PVC: used to make electrical wires, shoes, gaskets, etc.

So we can see that plastic beads are being used more and more. Therefore, customers need to choose a reputable address to order and own the best quality products right away.

Showing 1–16 of 19 results