Mô tả

Hạt nhựa PA6 là gì?

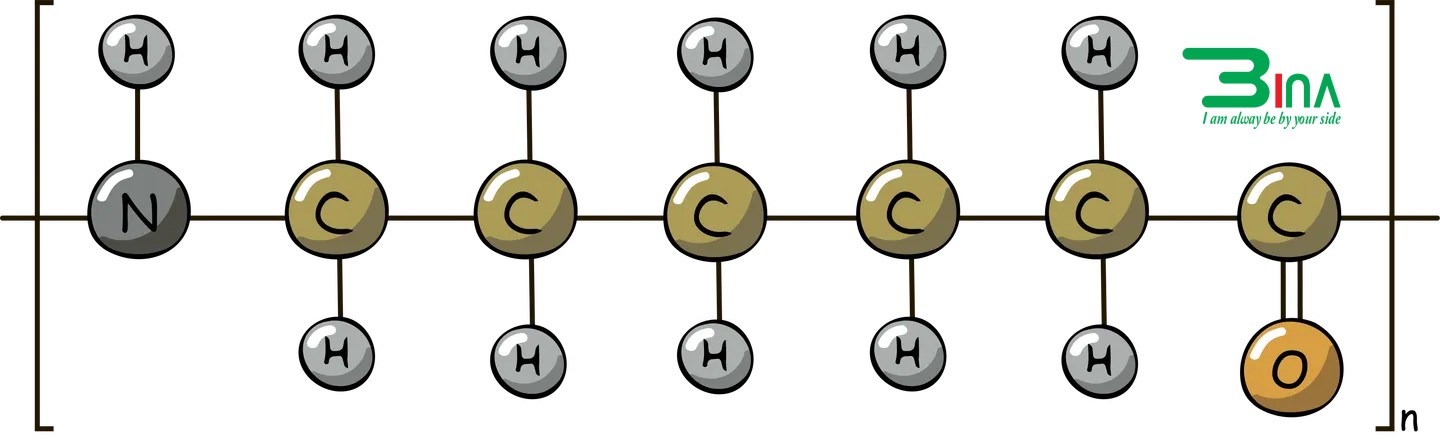

Polyamide 6 (PA6, Nylon 6) được sản xuất bằng cách trùng hợp mở vòng của caprolactam. Nylon 6 là một loại nhựa kỹ thuật bán tinh thể có sự cân bằng tốt giữa các đặc tính cơ học và nhiệt, khả năng chống va đập, khả năng chống hóa chất và ma sát và mài mòn thấp. Nylon 6 được xử lý bằng tất cả các phương pháp xử lý thông thường.

|

Các ứng dụng tiêu biểu của Nylon 6 bao gồm các thành phần ô tô bên trong, bên ngoài và dưới mui xe, các thành phần điện và điện tử, đầu nối, đồ nội thất văn phòng, dao kéo và đồ nấu ăn, dụng cụ làm vườn và chăm sóc bãi cỏ, sợi và sợi nhỏ, và màng phim.

Đặc điểm của Polymer:

- Độ bền và độ cứng tốt

- Khả năng chịu nhiệt tốt

- Độ va đập/độ bền tốt

- Khả năng chịu hóa chất tốt

- Tính chất ma sát tốt

- Khả năng chống biến dạng tốt

Điểm số:

- Sợi thủy tinh

- Hạt thủy tinh

- Sợi aramid

- Sợi carbon

- Sợi thủy tinh/gia cố khoáng chất

- Khoáng chất

- Chống cháy

- Ổn định tia cực tím

- Cấp độ chống thủy phân

- Đã sửa đổi tác động

- Có nhân

- Bôi trơn

- Ổn định nhiệt

Phương pháp chế biến

- Ép phun

- Ép đùn

- Ép đùn đồng thời

- Ép thổi

- Màng

Ứng dụng tiêu biểu

- Đầu nối, công tắc

- Giá đỡ, vỏ

- Ống nạp, bình chứa nước làm mát, tay nắm cửa, vỏ gương

- Bánh răng, cam, ổ trục

- Tay cầm máy hút bụi

- Bu lông

- Vỏ dụng cụ điện

- Thay thế kim loại

Nylon 66 có những ưu điểm sau so với Nylon 6:

Nylon 66 có những ưu điểm sau so với Nylon 6:

- Khả năng chịu nhiệt cao hơn

- Độ bền cao hơn

- Độ cứng cao hơn

- Hấp thụ độ ẩm thấp hơn

- Khả năng chống mài mòn tốt hơn

Nylon 6 có những ưu điểm sau so với Nylon 66:

- Mật độ thấp hơn một chút

- Độ dẻo dai tốt hơn

- Bề mặt đẹp hơn

- Nhiệt độ xử lý thấp hơn

- Trong nhiều ứng dụng, Nylon 6 và Nylon 66 có thể hoán đổi cho nhau.

Đánh giá

Chưa có đánh giá nào.