Mô tả

Giới thiệu về hạt nhựa POM

Nhựa polyoxymethylene (POM), còn được gọi là acetal hoặc polyacetal, là một loại nhựa kỹ thuật hiệu suất cao được sử dụng rộng rãi trong nhiều ngành công nghiệp khác nhau do có các đặc tính vật lý và hóa học tuyệt vời. Trong bài viết này, chúng ta sẽ khám phá các đặc điểm của hạt nhựa POM và giới thiệu các loại POM cụ thể, nêu bật những ưu điểm và ứng dụng của chúng.

|

|

|

Đặc điểm cơ bản của vật liệu POM

- Độ bền và độ cứng cao: Nhựa POM tự hào có độ bền cơ học và độ cứng ấn tượng, khiến nó trở nên lý tưởng cho các thành phần chịu tải trọng đáng kể. Ví dụ, Delrin® (một thương hiệu POM nổi tiếng) được công nhận về độ bền kéo đặc biệt, cho phép hoạt động đáng tin cậy trong các ứng dụng đòi hỏi khắt khe.

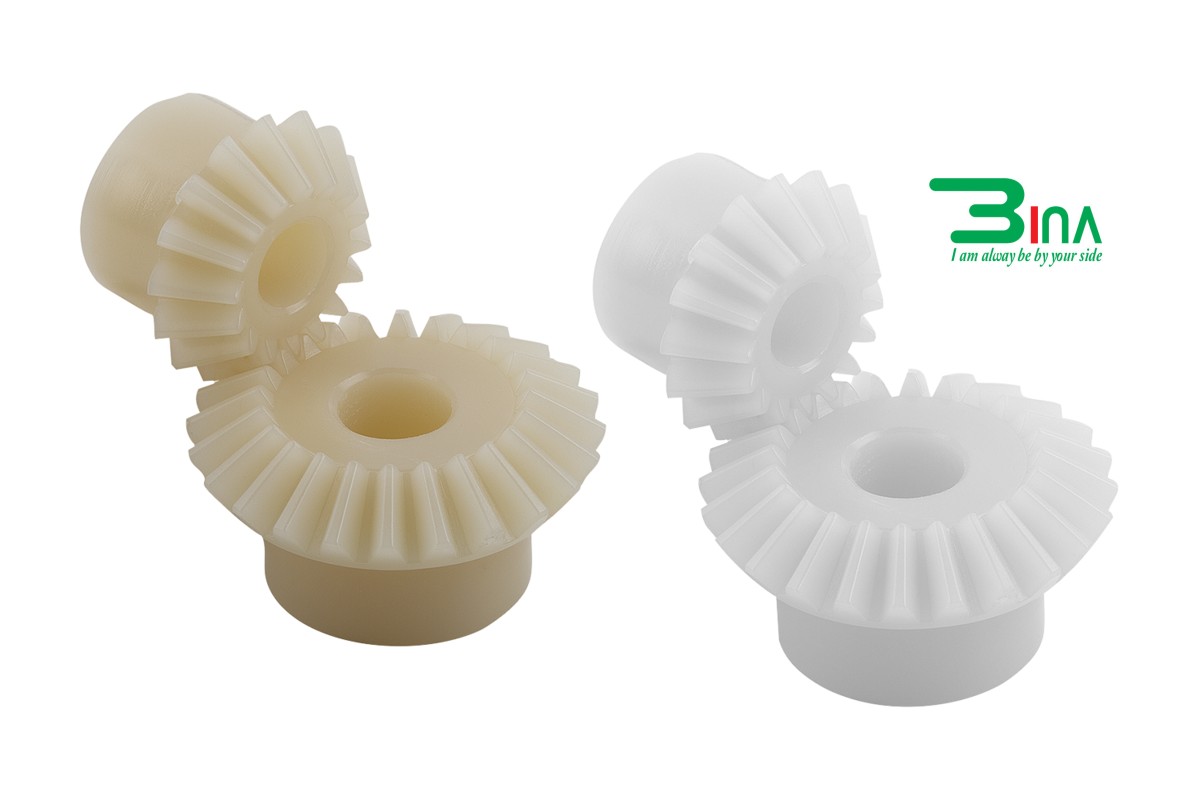

- Khả năng chống mài mòn tuyệt vời: Với hệ số ma sát thấp, POM phù hợp để sản xuất bánh răng, ổ trục và các thành phần khác chịu ma sát. Các sản phẩm như POM-C đặc biệt được ca ngợi vì khả năng chống mài mòn vượt trội, giúp tăng tuổi thọ của các bộ phận cơ khí.

- Độ ổn định hóa học: POM thể hiện khả năng chống chịu mạnh mẽ với nhiều loại hóa chất khác nhau, chẳng hạn như dung môi, dầu và nhiên liệu. Đặc tính này làm cho nó phù hợp cho các ứng dụng trong môi trường khắc nghiệt. Ví dụ, POM-H (cấp đồng trùng hợp) có khả năng chống hóa chất được cải thiện, khiến nó trở thành lựa chọn ưu tiên cho hệ thống nhiên liệu ô tô.

- Dễ gia công: Hạt nhựa POM có thể dễ dàng được gia công thông qua quá trình đúc phun và đùn, khiến nó trở nên lý tưởng cho sản xuất các bộ phận phức tạp. Sự sẵn có của các cấp như Acetal Copolymer (POM-C) đảm bảo rằng các nhà sản xuất có thể chọn một công thức phù hợp nhất với phương pháp gia công của họ.

- Độ ổn định nhiệt: POM có nhiệt độ biến dạng nhiệt cao, cho phép nó duy trì tính toàn vẹn ở nhiệt độ cao. Tính chất này rất quan trọng trong các ứng dụng như linh kiện ô tô, nơi nhiệt độ dao động có thể đáng kể.

|

|

|

Ứng dụng của vật liệu POM

- Ngành công nghiệp ô tô: Vật liệu POM được sử dụng trong bánh răng, ổ trục, van và hệ thống nhiên liệu. Độ bền và khả năng chống hóa chất của nó đảm bảo hiệu suất đáng tin cậy trong những điều kiện khắc nghiệt mà các linh kiện ô tô phải đối mặt.

- Điện tử: Vật liệu POM được sử dụng rộng rãi cho nhiều thành phần khác nhau, bao gồm đầu nối điện, công tắc và vỏ. Các đặc tính cách điện tuyệt vời của nó có hiệu quả ngăn ngừa rò rỉ điện và đoản mạch, đảm bảo an toàn và chức năng của các thiết bị. Ngoài ra, khả năng chịu nhiệt của POM cho phép nó chịu được ứng suất nhiệt trong quá trình vận hành, khiến nó trở thành lựa chọn đáng tin cậy cho môi trường nhiệt độ cao

- Thiết bị gia dụng: Nhựa POM thường được tìm thấy trong nhiều thành phần của các thiết bị gia dụng như tủ lạnh, máy giặt và máy rửa chén. Độ ổn định hóa học đáng chú ý của nó đảm bảo rằng nó có thể chịu được tiếp xúc với chất tẩy rửa và các chất tẩy rửa khác, trong khi độ bền của nó đảm bảo hiệu suất lâu dài. Điều này làm cho POM trở thành vật liệu thiết yếu để nâng cao độ tin cậy và hiệu quả của các thiết bị hàng ngày.

- Máy móc công nghiệp: Viên POM được sử dụng trong sản xuất nhiều thành phần cơ khí, bao gồm các thiết bị truyền động, thanh dẫn hướng và các bộ phận quan trọng khác. Các đặc tính hiệu suất cao và khả năng chống mài mòn đặc biệt của nó làm cho nó trở nên lý tưởng cho các ứng dụng chịu được ứng suất và ma sát đáng kể. Điều này đảm bảo độ tin cậy và tuổi thọ, góp phần vào hiệu quả chung của máy móc và thiết bị.

Cân nhắc về môi trường và toàn bộ vật liệu POM

Khi xử lý nhựa POM, điều kiện cần thiết là phải thêm thủ công các hướng dẫn về an toàn, vì sự phân hủy ở nhiệt độ cao có thể tạo ra khí độc độc hại. Việc làm thủ công các tiêu chuẩn an toàn và các biện pháp thực hành tốt nhất đảm bảo môi trường làm việc an toàn.

Các loại nhựa POM cụ thể

- Delrin® 500: Đây là viên POM ép phun có độ lưu động tuyệt vời, độ cứng cao, khả năng chịu nhiệt độ cao, khả năng chống ăn mòn và chống mài mòn. Vật liệu POM DuPont 500P phù hợp cho các ứng dụng trong môi trường khắc nghiệt và thường được sử dụng cho các bộ phận ô tô, bộ phận hàng không vũ trụ

- Delrin® 100: Đây là một loại viên POM ép phun và đùn có độ dẻo dai tốt, độ bền cao và hiệu suất xử lý tốt. Vật liệu POM DuPont 100P phù hợp với các tình huống chung, chẳng hạn như sản xuất bánh răng, hộp số và ổ trục cho các thiết bị gia dụng.

- Celanese C13031: Đây là vật liệu POM có thể sử dụng trong các ứng dụng tiếp xúc nhiên liệu, có đặc tính chịu nhiệt độ cao, chịu dung môi, độ bền cao và độ cứng cao. Do tính lưu động tuyệt vời của hạt POM C13031, rất phù hợp để sản xuất các bộ phận nhiên liệu ô tô.

Đánh giá

Chưa có đánh giá nào.