PE FILM

What is PE film? Everything you need to know about PE film for packaging and packaging

PE – polyethylene film is a common substrate used in food packaging, plastic bags. In addition, PE film is often hot pressed and manufactured into plastic bottles, medical packaging, and other packaging applications.

PE film is applied in many packaging fields, most commonly in the following two forms:

- Shrink film

- Stretch film for pallet wrapping

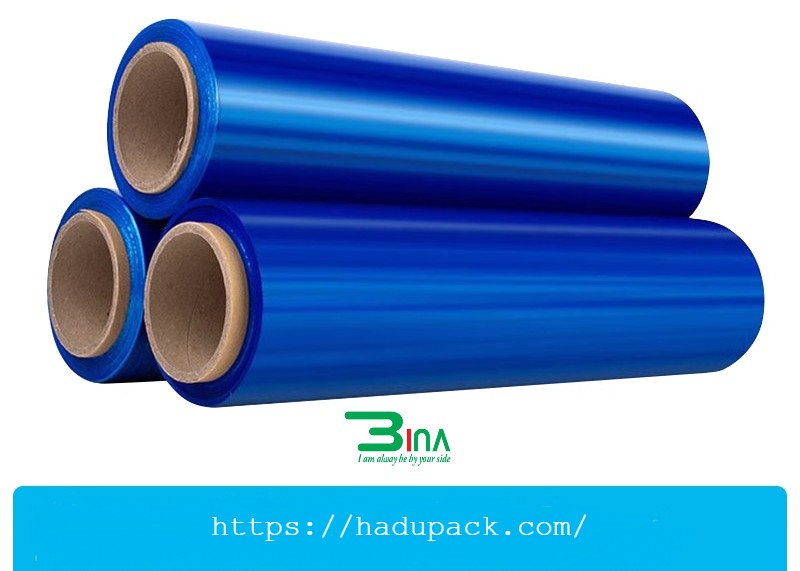

PE film roll is a type of film made from thermoplastic, high elasticity used to wrap and wrap around goods, electronic components, items that need to be stored from dust and moisture… Elasticity Their good quick recovery helps to secure connected goods and items tightly and tightly.

Heat shrinkable, sealing films allow for easy and economical packaging, protecting products from contamination or damage, or from moisture and dryness during storage and handling.

See more: Plastic bag

Main features of PE film, packing film

- Resistant to water and most chemicals.

- 100% recyclable. anti-static, anti-ultraviolet

- Melts at 120°C

- High strength, good expansion ratio make PE film can wrap many irregular shaped products.

- The original polyethylene film is transparent, but many colors can be produced by adding colorants.

Is PE film, Shrink film, Chit film toxic?

The answer is: no. In fact, Polyethylene Film is commonly used in food handling. It can be toxic if inhaled and/or absorbed into the skin or eyes as a vapor or a liquid (i.e. during manufacturing), but once formed it is non-toxic.

Other Polyethylene Films and Their Application in Packaging

PE film, PE Film for food packaging

Polyethylene film for food packaging is produced by Hoang Gia on modern lines to serve the food industry to keep food such as meat, fish, vegetables fresh for a long time.

Industrial PE film

This Polyethylene Film, This Polyethylene Film Roll is used for packaging in different areas of the industry. In particular, this problem is related to packaging in many manufacturing, machinery, and electronic goods industries. PE film can be rolled to protect from dirt, water and chemicals when cleaning the plant. Besides, industrial PE film has many advantages such as:

- Industrial wrapping film, protect goods from dirt or bacteria when storing or transporting. Create a standard environment to preserve goods for longer.

- Resistant to the ingress of steam

- Against situations where the surface of the goods is scratched

- Prevent theft or withdrawal of products. Limit fake goods

Polyethylene film for packaging in the pharmaceutical industry

Thanks to the safe raw materials used, the production system that meets the manufacturing quality standards and the very cleanliness of the factory, we are able to supply films for packaging for processing in the pharmaceutical industry.

LDPE co shrink film

LDPE shrink film is designed to create packaging film for many different products such as mineral water, fresh milk, bottled water. During packaging, the film heats up and then shrinks to wrap tightly around the packaged products. This is an economical and very convenient way of packing.

LDPE shrink film for pallet roll

Polyethylene film, LDPE pallet roll is convenient, available on the market, cheap price … and beautiful, so the demand for palletizing film is still increasing day by day.

LDPE film is used to wrap pallets of goods. The pallet film is heated and then cooled to shrink and wrap tightly around the pallet. This ensures the safe storage of goods and the safe handling of pallets.

Hand-rolled and machine-rolled PE stretch film

PE stretch film is a popular and economical packaging for pallets. The stretch film is wrapped around the pallet by hand or by the packing machine, the stretch film itself shrinks to protect the goods on the pallet.

Notes that must be avoided when using pe film:

- You need to clearly distinguish between shrink film and palletized pe film before using, because these two types of films are quite similar in appearance. Heat shrinkable film is better because it requires heat to wrap, different from pallet wrapping

- It is recommended to use machine wrap film instead of hand wrap film to save time, labor and cost.

- Do not arbitrarily destroy the membrane by burning or picking on the ground, throwing it into ponds and lakes.

- Store the wrap at room temperature. Do not use wrappers that are moldy, wrinkled, left for too long

PE stretch film innovations (industrial wrapping film/pe roll) with exceptional quality

The stability of PE stretch film is an important useful and highly applicable means of transporting goods, so we are confident to bring to the market quality shrink film, tight film and our reliable. Whether you are looking for a way to ensure the safety of your goods or the perfect transport of an entire container, you need to use our PE carrier. We have a wide range of export pe film products to suit every need and application

The company produces PE stretch film, Tight film, Shrink film

Currently, Hadupack has 3 factories producing polyethylene film, stretch PE film. PE roll film is strong and flexible. Products after being manufactured are checked in a private testing facility to ensure that each customer’s high standards of product quality are optimally met.

BiNa Vietnam International Co., Ltd. is a company that manufactures and supplies PE film throughout the northern region, specializing in providing comprehensive packaging solutions for production units and businesses.

Coming to Hadupack is the most optimal and economical solution for your packaging.

Showing 1–16 of 18 results