Mô tả

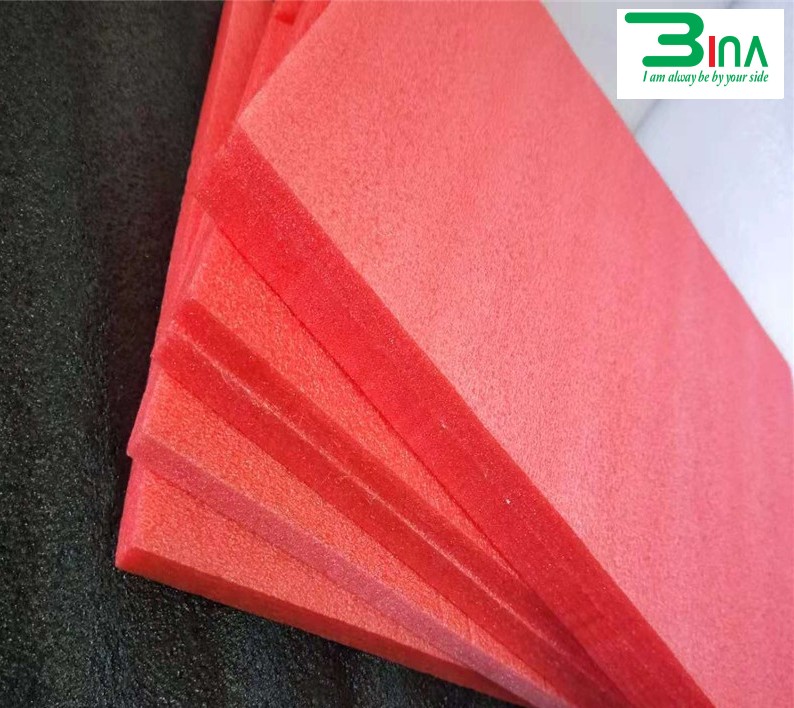

Bọt bảo vệ Polyethylene (PE) màng xốp pe foam

Mút xốp PE foam hoặc màng xốp PE là vật liệu bền, nhẹ, đàn hồi, có ô kín. Nó thường được sử dụng để đóng gói hàng hóa công nghiệp và nông nghiệp do có đặc tính cách nhiệt và giảm rung tuyệt vời. Nó cũng có khả năng chống hóa chất và độ ẩm cao. Bao bì mút công nghiệp của chúng tôi bao gồm túi mút PE, tấm, bó, khuôn cắt và ống. Chúng tôi tùy chỉnh bao bì mút bảo vệ của mình cho tất cả khách hàng.

|

Ưu điểm của màng xốp PE foam:

Được sản xuất từ cùng một vật liệu nền như màng xốp bong bóng, màng xốp PE có tất cả các tính năng tích cực giống nhau. Polyetylen (PE) có thể tái chế, hoàn toàn an toàn khi sử dụng và không có mùi. Vì màng xốp PE mềm nhẹ nên là giải pháp đóng gói hoàn hảo cho các sản phẩm mỏng manh và dễ vỡ. Màng xốp PE có khả năng hấp thụ sốc, ngăn ngừa hư hỏng do rung động và trầy xước, đồng thời bảo vệ khỏi bụi và độ ẩm. Màng xốp PE bao gồm 98% không khí và vì rất nhẹ nên lý tưởng để làm vật liệu đóng gói và giải pháp lấp đầy khoảng trống. Điều này giúp giảm chi phí vận chuyển và xử lý tốn kém.

|

- Độ nhạy bề mặt

- Tính linh hoạt

- Chi phí thấp

- Trọng lượng nhẹ

- Giảm xóc

- Chống nấm mốc

|

Thông số kỹ thuật của thước đo mút xốp PE:

- Trơn hoặc nhiều lớp

- Kích thước từ 1/32” đến 1/2” dày

- Thông thường hoặc chống tĩnh điện

Tùy chọn vật liệu xốp công nghiệp:

- Bọt polyetylen

- Bọt polypropylen

- Bọt nhiều lớp

- Bọt chống tĩnh điện

- Bọt cấp thực phẩm

|

Định dạng bao bì xốp PE:

- Túi xốp PE

- Tấm xốp

- Bó xốp

- Bọt đục lỗ trên cuộn

- Túi ngăn xốp

- Ống xốp

- Cắt khuôn xốp

- Túi xốp đục lỗ trên cuộn

Đánh giá

Chưa có đánh giá nào.