Mô tả

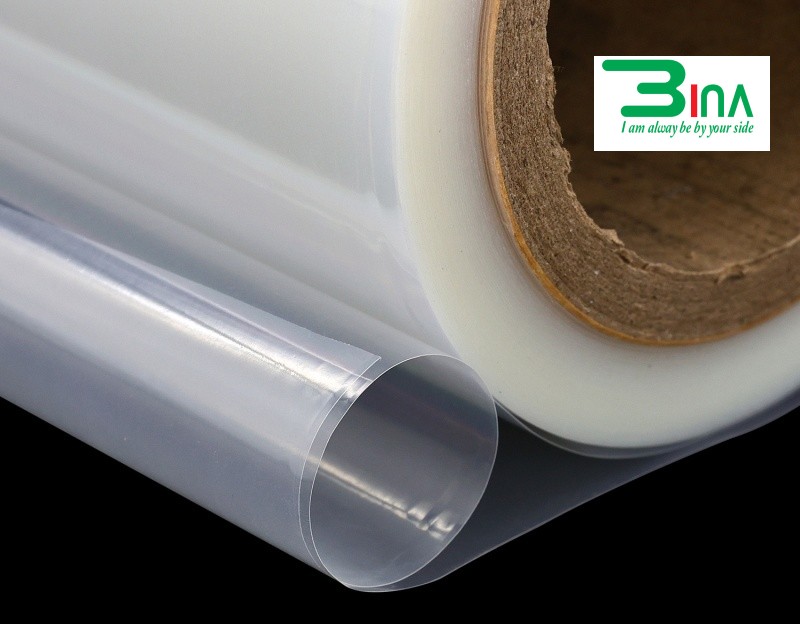

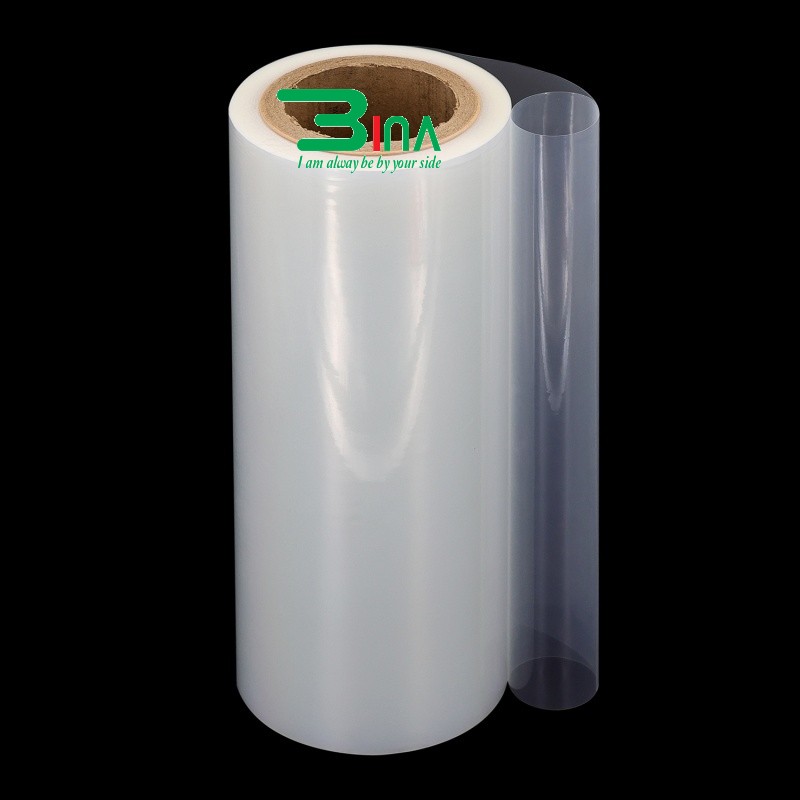

Màng PA là gì?

Màng PA trong ngành bao bì nhựa, thường có nghĩa là màng Polyamide định hướng hai trục (viết tắt là BOPA), vì quy trình định hướng hai trục sẽ cho phép sắp xếp phân tử ở trạng thái có trật tự hơn, giúp màng PA cuối cùng có độ bền cơ học, khả năng chịu nhiệt, độ trong suốt, v.v. tốt hơn, một màng nền tốt hơn cho mục đích đóng gói.

|

Màng nylon (viết tắt là NY), là biệt danh phổ biến nhất của màng PA, vì vậy khi bạn đến NY hoặc PA trong bao bì mềm, chỉ cần làm cho chúng giống nhau (thậm chí là các thương hiệu khác nhau trong một số trường hợp).

|

Nhựa PA – Polyamide (nylon)

Vật liệu PA, Polyamide hay thường gọi là nylon, là một loại nhựa nhiệt dẻo bán tinh thể có mật độ thấp và độ ổn định nhiệt cao. Nhựa nylon là một trong những loại nhựa xây dựng quan trọng nhất do khả năng chống mài mòn tuyệt vời, hệ số ma sát tốt và khả năng chịu nhiệt và độ bền va đập rất tốt. Các ký hiệu cho nhựa Polyamide thường đi kèm với các số như PA 6, PA 66, PA 12 và PA 46. Các số này đề cập đến cấu trúc phân tử của polyme PA. Mỗi loại cấu trúc cung cấp các đặc tính khác nhau. Các đặc tính polyamide này thay đổi từ PA 6.6 cứng và dai đến Polyamide loại 6 đến vật liệu polyamide 12 mềm và dẻo. Tùy thuộc vào loại, điểm nóng chảy của PA nằm trong khoảng từ 220 °C đến 260 °C. Các polyme nylon được sử dụng phổ biến nhất là PA 6 và PA 66. Nhựa PA 6 có thể thu được dưới dạng nylon đùn, đúc phun hoặc đúc khuôn.

|

Vì vật liệu nylon có thể dễ dàng được xử lý do đặc tính của nó, nên có nhiều biến thể polyamide. Bằng cách thêm các chất phụ gia như sợi thủy tinh cho nylon chứa thủy tinh hoặc sợi carbon cho nylon chứa carbon, độ bền và độ cứng ở cấp độ cụ thể có thể tăng lên nhiều lần khi cần thiết.

Vật liệu PA cũng được đặc trưng bởi khả năng chống hóa chất rất tốt và là loại nhựa đặc biệt chống dầu. Nhờ các đặc tính tuyệt vời của nhựa Polyamide này, đặc biệt là sự kết hợp giữa độ bền cao, độ dẻo dai và trọng lượng thấp, nhựa PA lý tưởng để thay thế kim loại. Các bộ phận ô tô, van công nghiệp, vật liệu cách nhiệt cho tà vẹt đường sắt và các ứng dụng kỹ thuật khác được làm từ polyme polyamide. Đối với các ứng dụng trong ngành thực phẩm, nylon cấp thực phẩm được sử dụng.

Một đặc tính điển hình của nylon là hấp thụ nước. Tùy thuộc vào loại, polyamide hấp thụ các lượng độ ẩm khác nhau. Do đó, thiết kế của các bộ phận như vậy phải tính đến khả năng hấp thụ nước của nylon và sự thay đổi liên quan về kích thước và tính chất cơ học.

Đánh giá

Chưa có đánh giá nào.