PLASTIC STRAPPING

What is plastic strapping?

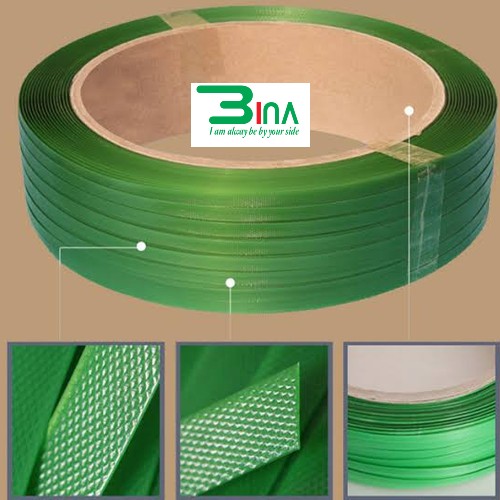

Plastic strapping can be understood simply as a product made from plastic resin (usually PP and PET plastic). Create filament or flat belts for the purpose of assisting in packing cartons, packing goods and fixing goods in a professional and efficient manner. Products are widely used in all markets such as industrial parks, business parks, domestic and foreign companies.

Plastic strapping is one of the packaging materials with high strength and breaking force used in many different types of packaging including cartoning, packing, tote security, plastic bricking and tying together both The material is packed for refrigeration and not refrigerated to be transported outside and transported within the factory. Plastic belts include 2 types: pet straps and pp straps. Plastic strapping is very economical, offers a unique combination of high strength with elasticity, is cost effective and recyclable. Plastic straps are moisture resistant and effective over a wide temperature range. Plastic straps can be used outdoors for limited periods with stable UV levels.

Raw materials for the production of plastic belts

Plastic straps are made primarily from one of two different types of flexible plastic: Polypropylene (PP) or Polyester (PET). Nylon is another option but much less popular these days. Polypropylene straps are usually made from virgin plastic or a virgin/recycled blend depending on the quality required for the intended use of the pp belt. Packing Solution’s straps only use virgin PP for our machine belts because of the impact of strap quality on the machine and the efficiency of packaging.

PET straps are made from up to 100% recycled plastic, including recycled bottle flakes or recycled plastic beads because PET plastic can be reused continuously and the quality is almost unchanged between each use.

How are plastic straps produced?

Commercial PP and strapping PET are produced using either extrusion processes. Multi-strand extrusion belts, the most common, are individually extruded through a multi-hole die, and then heated, stretched, annealed, cooled, and rolled. Stretching aligns the polymer chains in the plastic to its length, increasing the tensile strength of the fiber and making it an effective packaging material. Sheet extrusion belting starts with a wide extrusion sheet oriented to both length and width and slit to the final width. Its tensile strength is less than that of a similar sized filament extrusion strap but other characteristics may make it a good choice for operation in some older machine designs.

Are plastic straps competitive with steel straps?

The low cost of PP strapping and the significantly differentiating properties help to minimize overlap and competition between PP and steel straps. However, PET and steel straps compete in some cases, typically to secure larger, heavier loads in transit.

Advantages of PET straps over steel straps include:

- Lower cost

- Safer to use thanks to softer edges and less kink when the belt is cut to remove

- Ability to absorb shock loads

- Less damage to product edges

- Leaves no rust

- Longer, lighter-weight coils are easier to handle and more efficient to handle

- Less wear and tear on applied machinery

Advantages of steel straps include:

- Resistance to elongation provides stability for very heavy products that are difficult to protect

- Less sensitive to sharp product edges, if corner guards are not used

- Effective over a wider temperature range

- Less sensitive to UV degradation if the product is stored outside for a long time

- Can be fabricated at higher breaking strength than PET for extremely heavy duty applications

Are plastic straps recyclable?

PET is the No. 1 recycled plastic, and PP is the 5th most recycled plastic. Because the quality of PET can be improved after recycling, PP belts decompose with each use and the recycling of PP belts is less. more common but still widespread. Many items from lawn furniture to carpets use recycled PP. Most recyclers require the strap to be chopped into small particles.

What other products compete with plastic belts?

Self-adhesive plastic and adhesive tapes, tapes and staples, effective for gluing conventional slotted cartons (where the lid edges align). Glue and pins keep the flaps closed while the tape seals the joints. They are widely used in parcel transportation. Plastic strapping is the packaging material of choice for larger or heavier boxes where package reinforcement is required. It is also a preferred solution for protecting and reinforcing cartons (the lid slides over the bottom).

Rolling film is a popular and effective material for securing transport units. It is especially preferred for unstable multi-layer loads, where it provides a compartment cover to maintain load integrity and cleanliness during handling and transportation. Straps are also used to secure the transport unit, often along with stretch wrap to stabilize additional product stacks for the added benefit of increased stretch wrap stability and cleanliness. Straps could be a lower cost, less plastic alternative to wrapping stretch and provide faster handling for shippers, while simplifying post-waste handling and recycling. used by the receiver.

Shrink film is a more specialized type of packaging that is usually used in conjunction with another device that applies heat to it. In a typical application, a “shrink bag” is placed over the packaged object, and when heat is applied, the bag shrinks to form a tight, seamless shell around the package providing strength and Monolithic. This is the appropriate packaging method for products that require a high degree of protection for reasons of product integrity, cleanliness or security. This technology is available for a wide range of products from small cosmetic packages to glass bottles for winter storage. It can be applied by hand holding the heating tool. Plastic strapping and shrink film are rarely in direct competition but sometimes work together.

Buy plastic straps at hadupack

Cost saving: With certified product quality, the plastic belt is tough, strong, less prone to wear, and can be used for a long time. Especially, it can be reused many times, reducing the cost of buying new wires.

- Reduce inventory costs: Hadupack has a warehouse larger than 2000m2, always available, needed, delivered within 24 hours, without interrupting the production process.

- Free shipping: BiNa Vietnam International Co., Ltd has a nationwide distribution system, free shipping when the quantity is enough. For remote provinces, the company will guide and send the goods to the reputable car dealership. For custom-made goods, delivery time is from 2 to 3, available goods can be shipped up to 24 hours from the time of receiving the order.

- Preferential payment: There is a debt policy, discounts, and special discounts for agents, distributors and retail customers who order in large quantities.

- Guaranteed quality: The product is always the latest and has a free return policy if the quality does not meet the technical requirements as announced by Hadupack.

Showing all 6 results