Mô tả

Màng BOPP là gì?

Màng BOPP là viết tắt của polypropylen định hướng hai trục. Một loại polypropylen (PP). Polypropylen là một loại polyme nhiệt dẻo còn được gọi là polypropene. Nó có bề mặt in lý tưởng và có thể được làm thành nhãn và nhãn dán cũng như hàng dệt may và một số

bộ phận và vật liệu nhựa khác nhau. BOPP là polypropylen, về cơ bản là được làm phẳng kéo dài. BOPP được hướng dẫn bởi một hệ thống kéo dài nó theo hai hướng. Đây là nơi phần định hướng hai trục (BO) của BOPP xuất hiện. Ba quy trình phổ biến nhất để

thực hiện BOPP là hoạt động tuần tự khung căng, hướng khung căng đồng bộ và quy trình bong bóng đôi. Vật liệu chính của BOPP PP là nhựa tổng hợp được sản xuất rộng rãi nhất trên thế giới sau polyetylen (PE). Sản xuất tiết kiệm trong khi vẫn mang lại các tính năng hiệu suất vô cùng hữu ích. Các ứng dụng phổ biến của polypropylen và BOPP là:

- • Nhãn bao bì

- • Hộp đựng thực phẩm

- • Sợi nhựa

- • Nhựa cấp y tế

- • Sản phẩm phòng thí nghiệm

- • Vải hiệu suất

◆Tìm hiểu thêm:

- https://hadupack.com/san-pham/mang-pe-mau/

- https://hadupack.com/san-pham/mang-bao-ve/

- https://hadupack.com/san-pham/khay-xop-pe-foam/

Đặc điểm của màng nhựa BOPP là gì?

BOPP có chung các đặc tính của các loại nhựa PP khác, bao gồm độ bền, khả năng chống mỏi, khả năng chống ẩm, độc tính rất thấp, các tùy chọn hoàn thiện linh hoạt và độ trong suốt có thể kiểm soát (nhà sản xuất có thể làm cho BOPP trong suốt, mờ đục hoặc tạo bất kỳ độ trong suốt nào giữa chúng). Trong khi nhãn dán và đề can dễ làm và dễ in, hầu hết các loại keo dán sẵn khó để lắp vào vật liệu. Những đặc điểm này rất tuyệt vời cho các nhãn an toàn thực phẩm lâu dài và các ứng dụng màng BOPP chung khác.

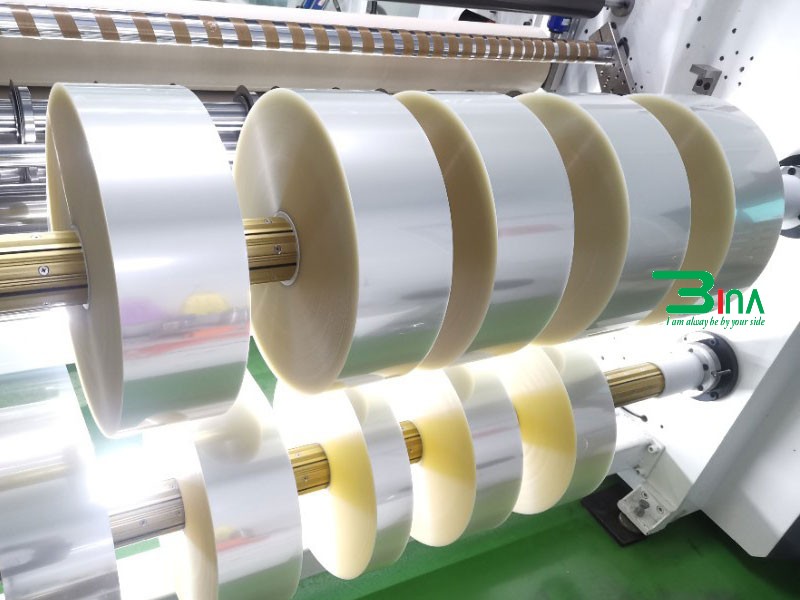

Quy trình sản xuất màng BOPP thường trải qua các bước sau:

- Đùn/thổi màng

- Định hướng màng theo 2 hướng

- Cắt màng/cuộn

- Tráng kim loại, hoặc tách 2 (nếu có).

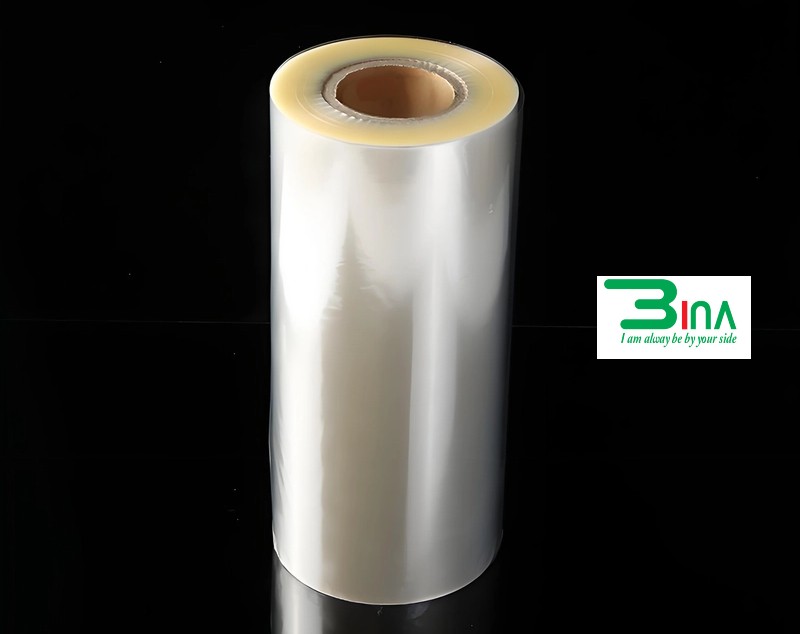

Với những đặc tính tốt như mịn, trong suốt, nhẹ và dễ in ấn, màng BOPP đã trở thành vật liệu không thể thiếu và được sử dụng rộng rãi trong nhiều ứng dụng nông nghiệp và công nghiệp như đóng gói, thực phẩm, dệt sợi, nhuộm vải, in ấn, văn phòng phẩm…

Kích thước màng tiêu biểu:

- Độ dày: 12mic, 15mic, 20mic, 25mic, 30mic, 35mic…

- Chiều rộng: theo yêu cầu của khách hàng

- Chiều dài: 6.000m, 8.000m, 12.000m,…

- Xử lý corona 1 mặt, 2 mặt…

Đánh giá

Chưa có đánh giá nào.