Mô tả

Màng bảo vệ bề mặt là gì?

Ngay cả khi bạn chưa từng sử dụng màng bảo vệ cho mục đích riêng của mình, bạn có thể đã quen thuộc với sự hiện diện của chúng trên nhiều sản phẩm mà bạn mua hàng ngày. Đến bây giờ, bạn có thể thực sự mong đợi tìm thấy màng bảo vệ trên mọi i-Something, TV, màn hình máy tính hoặc thiết bị gia dụng lớn mới mà bạn mua. Rất có thể khách hàng của bạn cũng mong đợi tìm thấy màng bảo vệ kỳ diệu đó trên các sản phẩm của bạn.

|

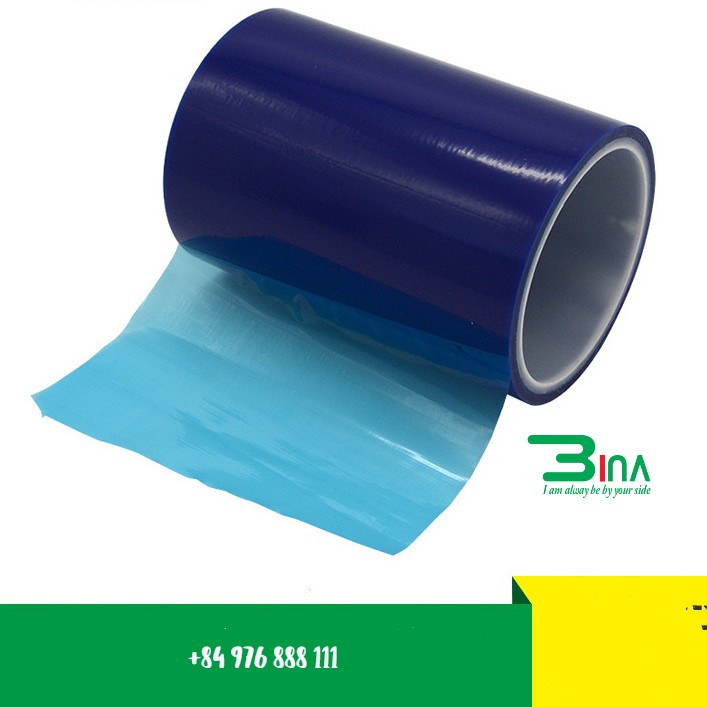

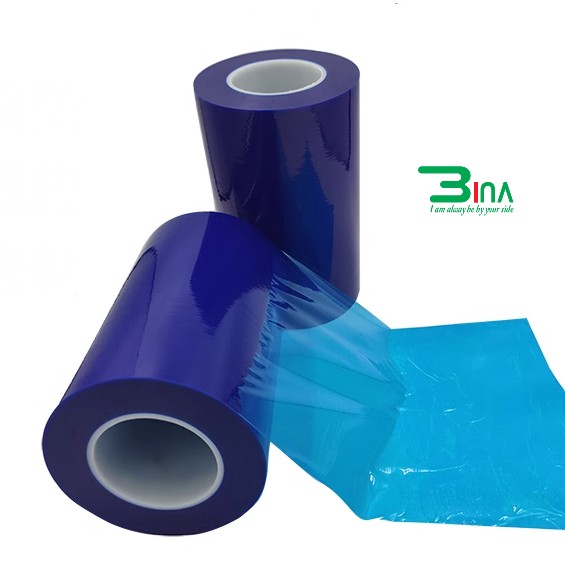

Ở dạng đơn giản nhất, màng bảo vệ bề mặt tạm thời là một lớp nhựa dày được phủ một lớp keo dán nhạy áp suất chuyên dụng (PSA). Một từ khóa khi mô tả chất kết dính màng bảo vệ là “tạm thời”. Theo thiết kế, màng bảo vệ bề mặt tạm thời không có ý định để lại trên bề mặt vô thời hạn. Tất cả chúng ta đều đã từng trải qua cảm giác khó chịu khi cố gắng gỡ bỏ một nhãn giá tạm thời khỏi một tiện ích mới và nhãn giá bị rách thành từng dải và/hoặc để lại cặn dính. Điều đó khá không mong muốn đối với một màng bảo vệ. Đọc Cách chọn màng bảo vệ để tránh điều đó xảy ra với màng bảo vệ của bạn.

|

|

◆Tìm hiểu thêm:

- https://hadupack.com/san-pham/mang-cang-pe/

- https://hadupack.com/san-pham/khay-xop-pe-foam/

- https://hadupack.com/san-pham/mang-bao-ve/

Sau đây là một số loại vật liệu cụ thể, chủ yếu là nhựa, thường được sử dụng để tạo màng bảo vệ:

- Màng polythene mật độ thấp có độ đàn hồi và độ linh hoạt được cải thiện và thường có trọng lượng nhẹ

- Polyvinyl clorua bóng mượt với mức độ đàn hồi tương đối cao hơn, khiến nó trở thành lựa chọn lý tưởng để bảo vệ bề mặt kim loại

- Polypropylene ít đàn hồi hơn và giữ chặt ngay cả ở nhiệt độ cao hơn

- Polyolefin hoạt động đặc biệt tốt với kính hoặc kim loại sơn và các biến thể cụ thể được sử dụng để đóng gói

- Polythene mật độ thấp được đùn đồng thời cung cấp mức độ bảo vệ cao hơn bằng cách sử dụng các kỹ thuật xếp lớp

- Giấy thường được sử dụng để bảo vệ chống lại thiệt hại do tác động rất thấp

PVC thường đắt hơn một chút và được sử dụng trong các ứng dụng đặc biệt, chẳng hạn như tạo hình kim loại và bảo vệ cửa sổ bên ngoài, nơi màng sẽ tiếp xúc với ánh sáng mặt trời trong tối đa một năm. LDPE đã được xử lý bằng chất ức chế tia UV cũng có thể được sử dụng cho các ứng dụng bên ngoài. Để tránh sự cố, không sử dụng màng được đánh giá là nội thất cho các ứng dụng bên ngoài.

|

Độ dày của màng thường được mô tả là độ dày kết hợp của nhựa và độ dày của chất kết dính. Ở Hoa Kỳ, màng được đo bằng hàng nghìn inch hoặc mils. (Không giống như milimét). Độ dày của màng thông thường dao động từ 1 mil đến 6 mil, đôi khi cao hơn. Màng càng dày thì khả năng bảo vệ chống mài mòn, trầy xước, v.v. càng cao. Màng dày hơn có xu hướng cứng hơn và có thể khó áp dụng hơn cho các bề mặt có đường viền.

Loại chất kết dính cũng là một cân nhắc quan trọng. Các bề mặt có kết cấu thường yêu cầu chất kết dính dày hơn và mềm hơn. Nếu keo chỉ tiếp xúc với “đỉnh” của bề mặt, keo có thể chỉ chạm tới dưới 5% tổng diện tích bề mặt và dễ bị rơi ra khỏi bề mặt. Keo dán cho bề mặt có kết cấu cũng có xu hướng có giá trị độ bám dính cao hơn.

Độ bám dính, hay độ dính của keo, được đo bằng ounce trên inch. Để có hiệu suất tốt nhất, nên sử dụng giá trị độ bám dính thấp nhất, bám dính đủ tốt để giữ lớp màng trên bề mặt trong suốt vòng đời của nó. Sử dụng mức độ bám dính cao hơn mức cần thiết có thể làm tăng nguy cơ lớp màng khó gỡ bỏ hoặc để lại cặn keo. Ví dụ, lớp màng bảo vệ được sử dụng để bảo vệ màn hình LCD trên điện thoại di động có độ bám dính khoảng một ounce/inch. Lớp màng được sử dụng để bảo vệ thảm có độ bám dính là 25 ounce/inch hoặc cao hơn. Sử dụng lớp màng thảm trên màn hình LCD có thể sẽ kéo màn hình ra khi lớp màng được gỡ bỏ.

|

|

|

|

|

|

|

|

|

|

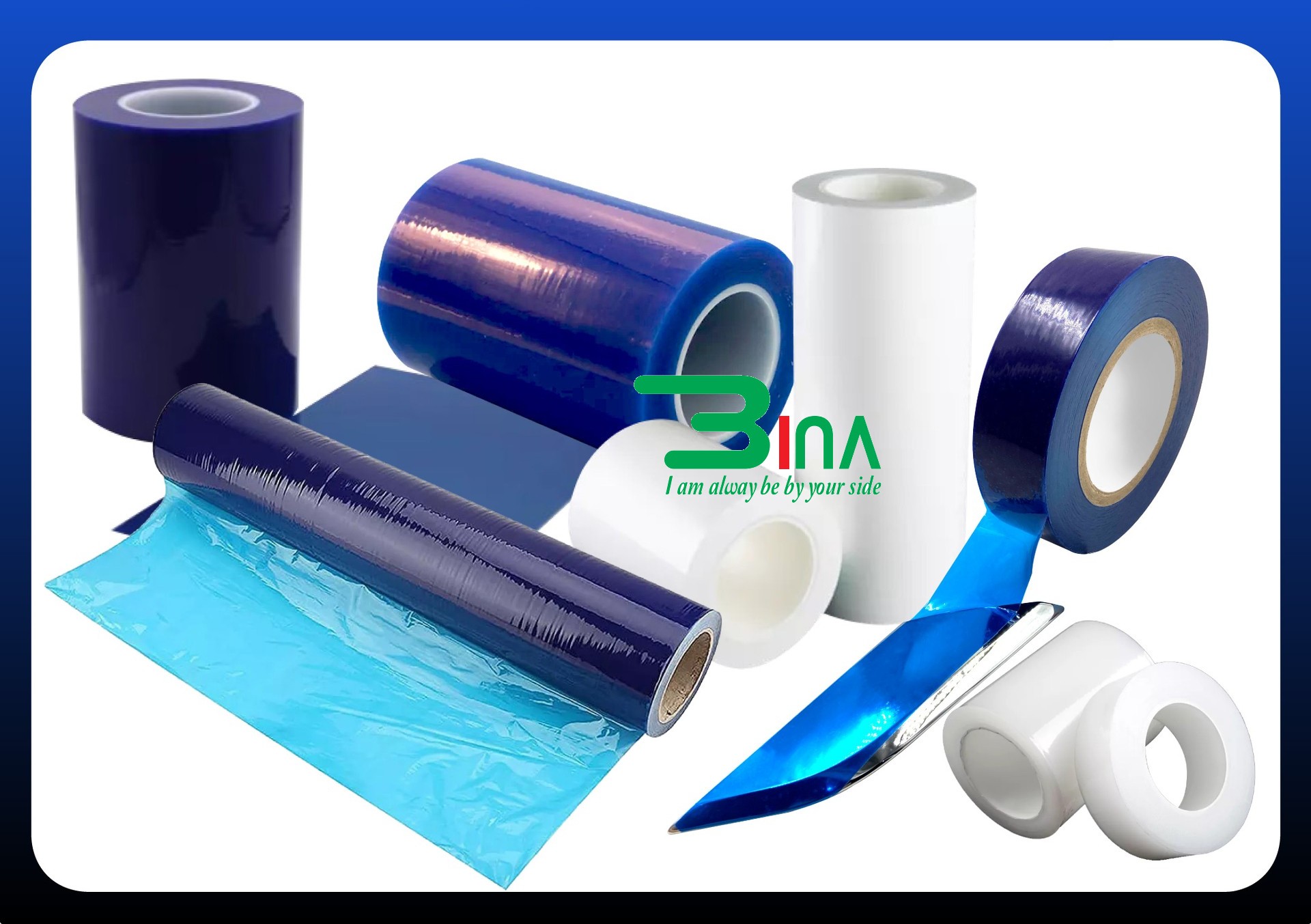

Các loại màng bảo vệ

Màng bảo vệ có nhiều kiểu dáng khác nhau, mỗi kiểu được thiết kế riêng cho một ứng dụng và chúng thường khác nhau tùy theo độ dày, vật liệu và độ bám dính. Đây là hai loại màng bảo vệ phổ biến nhất mà bạn sẽ gặp:

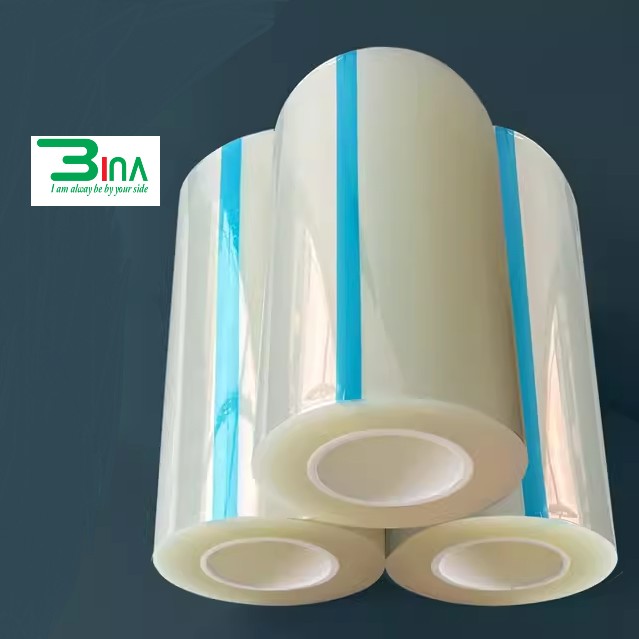

1. MÀNG BẢO VỆ BỀ MẶT

Màng bảo vệ bề mặt chất lượng cao có thể dễ dàng dán và tháo ra trong khi vẫn tạo được lớp hoàn thiện bóng bẩy cho bề mặt được sử dụng. Những màng này bảo vệ các bề mặt dễ bị tổn thương: kính, kính thương mại, nhựa, đá, gạch, đá granit, đá cẩm thạch, v.v.

Các ngành công nghiệp tập trung vào sản xuất và phân phối các sản phẩm đóng gói thường thấy mình cần loại bảo vệ này. Tuy nhiên, việc cắt những màng này thành các hình dạng phù hợp để phù hợp với nhiều bề mặt khác nhau trở nên khó khăn. Ngoài ra, người dùng phải đảm bảo không có bọt khí khi dán, điều này thường đòi hỏi chuyên môn của một chuyên gia về màng bảo vệ bề mặt.

|

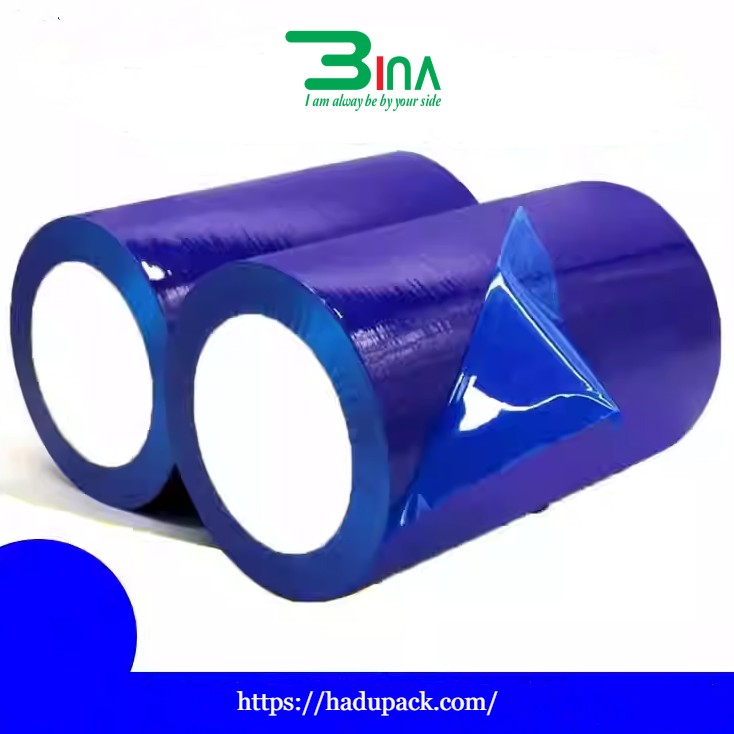

2. MÀNG BẢO VỆ CHO BỀ MẶT SƠN

Màng bảo vệ sơn thường có khả năng chống va đập cao hơn. Các biến thể như màng bảo vệ sơn trong suốt (PPF) có đặc tính “tự phục hồi” cho phép chúng trở lại hình dạng tự nhiên sau khi va chạm hoặc trầy xước.

Những loại màng này thường được làm từ polyme đàn hồi, mang lại độ đàn hồi cho màng. Theo truyền thống, chúng vô hình, cho phép vật thể duy trì giá trị thẩm mỹ của nó trong khi tăng thêm một mức độ bảo vệ. Đó là lý do tại sao những ứng dụng phổ biến bao gồm điện thoại di động, đồ điện tử, ô tô, máy bay và các thiết bị khác.

Mặc dù PPF không chống đạn, nhưng nó cung cấp khả năng bảo vệ vượt trội chống lại đá dăm và các chất gây ô nhiễm môi trường khác. Nó cũng có khả năng chống hóa chất, cho phép bạn rửa hoặc vệ sinh thiết bị của mình mà không sợ mất chất kết dính hoặc không thể thực hiện các biện pháp bảo trì.

|

Những lợi ích của việc sử dụng màng bảo vệ trong ngành là gì?

Các ứng dụng của màng bảo vệ rất đa dạng và gần như vô hạn. Tuy nhiên, trong các ngành hàng không vũ trụ, điện tử, công nghiệp, ô tô, y tế và quốc phòng, màng bảo vệ có thể đặc biệt quan trọng đối với chức năng. Trong các ngành công nghiệp sau, màng bảo vệ mang lại những lợi ích như bảo vệ khỏi trầy xước và mài mòn, bảo vệ khỏi độ ẩm và bụi bẩn, chống chịu nhiệt độ nóng hoặc lạnh, chống tia cực tím và chống hóa chất.

- HÀNG KHÔNG: Kỹ thuật hàng không vũ trụ luôn nỗ lực tạo ra thiết bị êm hơn, nhẹ hơn và chống hư hỏng. Trong ngành hàng không vũ trụ, màng bảo vệ rất cần thiết để kéo dài tuổi thọ và nâng cao chất lượng vật liệu máy bay.

- ĐIỆN TỬ: Các thiết bị điện tử như điện thoại di động và phần cứng khác dễ bị hư hỏng vật lý, đặc biệt là màn hình. Ngoài ra còn có nhiều khả năng ứng dụng cho các công ty sản xuất tivi, công ty vận chuyển hàng điện tử và các doanh nghiệp tương tự khác.

- CÔNG NGHIỆP: Nhìn chung, các ngành công nghiệp có nhiều ứng dụng rộng rãi cho màng bảo vệ và thường yêu cầu các miếng màng bảo vệ tùy chỉnh để phù hợp với thiết bị hoặc sản phẩm mới sản xuất. Các sản phẩm cuối cùng có thể bị hư hỏng nhiều khi di chuyển đến các trung tâm phân phối hoặc kho hàng.

- Ô TÔ: Từ bánh xe và cửa đến chắn bùn và cản, ô tô cần được bảo vệ toàn diện. Màng bảo vệ là một cách tuyệt vời để đạt được khả năng bảo vệ bề mặt chung mà không ảnh hưởng đến tính thẩm mỹ của xe.

- Y TẾ: Thiết bị y tế thường đắt tiền và cần bảo dưỡng nhiều để ngăn ngừa ăn mòn kim loại. Thêm lớp bảo vệ giúp ngăn ngừa hao mòn sớm và giúp máy móc hoạt động trơn tru.

- QUỐC PHÒNG: Thiết bị quốc phòng có thể cần các loại bảo vệ bề mặt mạnh hơn. Màng bảo vệ giúp đảm bảo thiết bị, vũ khí và máy móc quân sự quan trọng hoạt động hiệu quả.

|

|

Nên chọn loại phim bảo vệ nào?

Để chọn đúng loại phim phù hợp với nhu cầu của mình, bạn nên cân nhắc các yếu tố sau:

- Độ bền: Việc lắp đặt phim giá rẻ sẽ hỏng sau vài tháng là phản tác dụng. Thay vào đó, hãy đầu tư vào một loại phim có thương hiệu chất lượng cao, có độ bền cao.

- Bảo hành: Đảm bảo rằng sản phẩm bạn đang đầu tư có dịch vụ chăm sóc khách hàng uy tín và chế độ bảo hành tốt. Nhìn chung, Pregis PPF sẽ có thời hạn bảo hành lên đến mười năm. Điều này rất tuyệt vời đối với các thiết bị như ô tô mà bạn có thể sẽ sử dụng lâu dài.

- Chất lượng: Bây giờ bạn đã biết về vai trò của vật liệu trong việc xác định chất lượng của phim, hãy đảm bảo rằng bạn đặt câu hỏi về nó. Ít nhất, bạn phải có thể mua được loại PPF đáp ứng được tất cả các yêu cầu cơ bản về khả năng chống trầy xước, chống mài mòn và chống tia UV.

- Tất nhiên, chất lượng phụ thuộc vào ngân sách bạn có, nhưng nhìn chung, việc mua được loại phim chất lượng cao với giá cả hợp lý tương đối dễ dàng.

- Ứng dụng: Việc ứng dụng hoặc lắp đặt phim bảo vệ có thể là một thách thức, đặc biệt là khi bạn không có kinh nghiệm. Lý tưởng nhất là bạn nên thuê một chuyên gia để đảm bảo tránh được bọt khí trên bề mặt.

|

|

Cách sử dụng màng bảo vệ thành công

Không còn nghi ngờ gì nữa, chất lượng của vật liệu màng quyết định phần lớn đến việc nó có phù hợp với nhiệm vụ cần thiết hay không. Tuy nhiên, có hai khía cạnh quan trọng cần ghi nhớ về màng bảo vệ.

- Đầu tiên, hãy hợp tác với người hiểu về lựa chọn vật liệu nhiều kích thước và độ dày khác nhau, một số loại cung cấp khả năng bảo vệ nhiều lớp, mạnh hơn. Đối tượng càng phức tạp thì nhu cầu tùy chỉnh càng cao, đây là khía cạnh quan trọng thứ hai.

- Thứ hai, hãy lập kế hoạch thực hiện dự án của bạn: những tiến bộ hiện đại trong công nghệ cắt khuôn quay cho phép các bộ chuyển đổi đạt được kết quả chính xác ngay cả khi xử lý máy bay chuyên dụng cao và các đối tượng được thiết kế phức tạp khác. Việc ứng dụng màng bảo vệ cho các đối tượng phức tạp đòi hỏi phải có chuyên môn về làm việc với súng nhiệt, đèn khò, máy vẽ, lắp phun và các kỹ thuật lắp đặt khác.

Bạn có thể hình dung được cách màng bảo vệ sẽ mang lại lợi ích cho ngành cụ thể của mình, nhưng bạn có thể đang tự hỏi nên sử dụng loại nào hoặc khi nào bộ phận của bạn sẽ đạt đến thiết kế cuối cùng. Với kinh nghiệm làm việc với nhiều loại vật liệu, các kỹ sư của chúng tôi tại Hadupack biết rằng việc tìm đúng loại màng phim và tối ưu hóa thiết kế cho giải pháp sáng tạo của bạn là điều cần thiết.

Nếu bạn có ứng dụng màng phim bảo vệ, bước tiếp theo của bạn có thể là tìm một bộ chuyển đổi đáp ứng nhu cầu cụ thể của bạn. Tại Hadupack, chúng tôi tự hào về khả năng cung cấp các bộ phận được tùy chỉnh cao phù hợp với nhu cầu cụ thể của sản phẩm và ứng dụng của bạn.

Đánh giá

Chưa có đánh giá nào.