Mô tả

Màng co nhiệt PVC – POF – PE là gì?

Màng co nhiệt vật liệu được tạo thành từ màng nhựa polyme. Khi được áp dụng nhiệt, nó co lại chặt chẽ trên bất cứ thứ gì nó bao phủ. Có nhiều cách sử dụng màng co và màng co. Một số ứng dụng màng co thông thường là để bọc thực phẩm, giỏ quà, hộp, đồ chơi, sách, xà phòng, v.v. Dưới đây là phân tích về hai loại màng co được sử dụng phổ biến nhất.

|

|

|

Màng co PVC – Một loại màng co được sử dụng cho nhiều ứng dụng khác nhau. PVC là viết tắt của Polyvinyl clorua. Polyvinyl clorua là loại nhựa được sản xuất nhiều thứ ba trên thế giới. Màng co PVC là loại màng co được sử dụng phổ biến nhất cho đến khi được thay thế bằng màng co polyolefin (POF) cách đây vài năm.

Công dụng phổ biến của màng co PVC – Các ứng dụng của màng co PVC bao gồm hộp đóng gói, bao bì CD và DVD, phần mềm, hộp nhỏ và các mặt hàng không ăn được khác.

Nhược điểm của màng co PVC – Độ bền bịt kín, vấn đề lưu trữ và các sản phẩm phụ bịt kín là những nhược điểm phổ biến của màng co PVC. Chất hóa dẻo trong màng co PVC cứng lại trong điều kiện lạnh và mềm ra trong điều kiện nóng, do đó làm giảm độ bền của lớp niêm phong và nhựa. Màng co PVC cũng giải phóng một lượng nhỏ hydro clorua vào không khí và cặn cacbon bám vào chất bịt kín. Cần thông gió thích hợp khi niêm phong màng co PVC.

|

Màng co polyolefin – Một loại màng co đã trở thành lựa chọn ưa thích để đóng gói các sản phẩm, cả thực phẩm ăn được và không ăn được. Màng co polyolefin được ưa chuộng vì nhiều lý do, bao gồm ít mùi hơn khi niêm phong, độ kín chắc hơn và lưu trữ linh hoạt hơn. Màng co polyolefin không có bất kỳ chất hóa dẻo nào, do đó, chúng không tạo ra khí hydro clorua. Màng co polyolefin không có bất kỳ chất hóa dẻo nào, do đó nhiệt độ không phải là vấn đề. Polyolefin có thể được lưu trữ trong nhiều phạm vi nhiệt độ khác nhau và không cứng lại hoặc mềm ra trong các môi trường khác nhau như màng co PVC.

Công dụng phổ biến của màng co polyolefin – Màng co polyolefin được sử dụng cho hầu hết mọi loại ứng dụng. Các ứng dụng bao gồm đồ chơi, đồ dùng thể thao, màng in, thực phẩm, văn phòng phẩm và thiệp, chỉ kể đến một vài ứng dụng.

Nhược điểm của màng co Polyolefin – Chi phí và khả năng tương thích với máy là hai nhược điểm đáng kể của màng co Polyolefin. Polyolefin thường đắt hơn màng co PVC. Nhiều nhà đóng gói thích PVC vì lý do này. Có nhiều loại màng co polyolefin tương thích hơn với máy móc, nhưng khả năng tương thích với máy móc Polyolefin là vấn đề của các nhà đóng gói.

Màng co polyolefin liên kết chéo – Chiếu xạ được áp dụng cho màng co polyolefin tiêu chuẩn để làm cho màng chắc hơn và có khả năng bịt kín tốt hơn. Màng co liên kết chéo là vô trùng và được FDA chấp thuận cho tiếp xúc trực tiếp với thực phẩm. Nó mang lại độ trong tuyệt vời để trưng bày các sản phẩm đóng gói. Để xem chi tiết về quá trình sản xuất và lịch sử của màng co liên kết chéo, hãy xem bài đăng trên blog của chúng tôi có tiêu đề Màng co liên kết chéo là gì.

|

Màng co liên kết chéo cũng để lại ít cặn hơn trên máy dán, giúp lưỡi cắt hoặc dây dán kéo dài tuổi thọ. Màng co liên kết chéo được sản xuất để sử dụng với máy tốc độ cao và hoạt động năng suất cao.

Công dụng phổ biến của màng co polyolefin liên kết chéo – Màng co liên kết chéo được sử dụng với các sản phẩm giống như màng co polyolefin tiêu chuẩn. Màng liên kết chéo thường được sử dụng trong các hoạt động sản lượng cao. Nó cũng có thể được sử dụng cho các sản phẩm nặng hơn; màng co polyolefin thông thường không thể đóng gói đúng cách.

Nhược điểm của màng co polyolefin liên kết chéo – Màng co liên kết chéo yêu cầu nhiệt độ co và niêm phong cao hơn so với màng co polyolefin tiêu chuẩn. Nhiệt độ cao hơn có thể làm hỏng và biến dạng các sản phẩm nhạy cảm với nhiệt. Nhiệt độ co và niêm phong cao hơn. Ngoài ra, yêu cầu chi phí năng lượng cao hơn.

|

Màng co Polyethylene – Màng co Polyethylene được sử dụng để đóng gói các sản phẩm nặng hơn. Màng co Polyethylene (màng bó) thường được đùn thành các cuộn đơn hoặc cuộn phẳng. Các cuộn được sử dụng trên các máy bó co có thanh niêm phong và đường hầm co.

Nhược điểm của màng co Polyethylene – Màng co Polyethylene yêu cầu phải có máy bó co để vận hành sản phẩm hiệu quả. Máy bó co có đường hầm co có thể đắt và tốn hàng nghìn đô la. Màng co Polyethylene cũng yêu cầu tiếp xúc với nhiệt trong thời gian dài hơn để co hoàn toàn. Các sản phẩm nhạy cảm với nhiệt có thể tan chảy hoặc bị hư hỏng trong khi màng co đang co hoàn toàn. Màng co Polyethylene có tỷ lệ co thấp là 15% trở xuống. Các phép đo sản phẩm là điều cần thiết để đảm bảo mua đúng kích thước cuộn co.

|

|

| Độ dày | Vật liệu | Đặc điểm | Nhiệt độ co trung bình | Tốc độ co trung bình | Công dụng chung |

| 45 gauge | Polyolefin liên kết chéo | Màng mỏng có khả năng chống đâm thủng tối thiểu và mềm mại khi chạm vào, Độ trong tuyệt vời | 300°-350° F | 25%-35% | Danh thiếp, đồ nướng, sản phẩm đồng phục nhẹ |

| 60 gauge | Polyolefin | Màng mỏng mềm mại khi chạm vào với độ bền niêm phong nhẹ, Độ trong tuyệt vời | 300°-350° F | 30% | Sản phẩm in, đồ chơi nhỏ, trò chơi cờ bàn, đồ nướng |

| 60 gauge | Polyolefin liên kết chéo | Màng mỏng mềm mại khi chạm vào với lớp niêm phong chắc chắn hơn và tăng khả năng chống thủng, Độ trong suốt tuyệt vời | 300°-350° F | 25%-35% | Bao bì sản lượng cao hơn cho đồ chơi nhẹ, đồ thủ công, đồ lưu niệm và các vật dụng nhẹ khác |

| 75 gauge | PVC | Độ dày màng tiêu chuẩn trở nên cứng sau khi chịu nhiệt, Độ trong suốt tốt | 200°-300° F | 30%-40% | DVD, CD, hàng hóa không tiêu thụ |

| 75 gauge | Polyolefin | Độ dày màng tiêu chuẩn, mềm khi chạm vào, có khả năng chống đâm thủng và độ bền niêm phong tốt. Độ trong suốt tuyệt vời | 300°-350° F | 30% | Màng co nhiệt phổ biến nhất, Mọi thứ từ pizza đến các sản phẩm gỗ và kim loại |

| 75 gauge | Polyolefin liên kết chéo | Mạnh hơn polyolefin 75 gauge tiêu chuẩn, tốt hơn với máy tốc độ cao. Độ trong tuyệt vời | 325°-400° F | 25%-35% | Nhiều loại sản phẩm thường có trọng lượng dưới 12-15 lbs. |

| 100 gauge | PVC | Một lớp màng dày và bền, cứng lại và trở nên cứng sau khi chịu nhiệt, độ trong suốt tuyệt vời | 275°-325° F | 30%-40% | Sách nặng hơn, xương chó, băng co xung quanh các sản phẩm chai lên đến 20 lbs. |

| 100 gauge | Polyolefin | Mềm mại khi chạm vào, có khả năng chống đâm thủng và độ bền niêm phong tốt. Độ trong suốt tuyệt vời | 350°-375° F | 30% | Được sử dụng để vận chuyển sản phẩm và đóng gói sản phẩm lên đến 25 lbs. |

| 100 gauge | Polyolefin liên kết chéo | Giống như polyolefin 100 ga. với khả năng chống đâm thủng và độ bền niêm phong mạnh hơn. Độ trong suốt tuyệt vời | 350°-425° F | 25%-35% | Các sản phẩm nặng hơn lên đến 30 lbs, trong các hoạt động sản lượng cao |

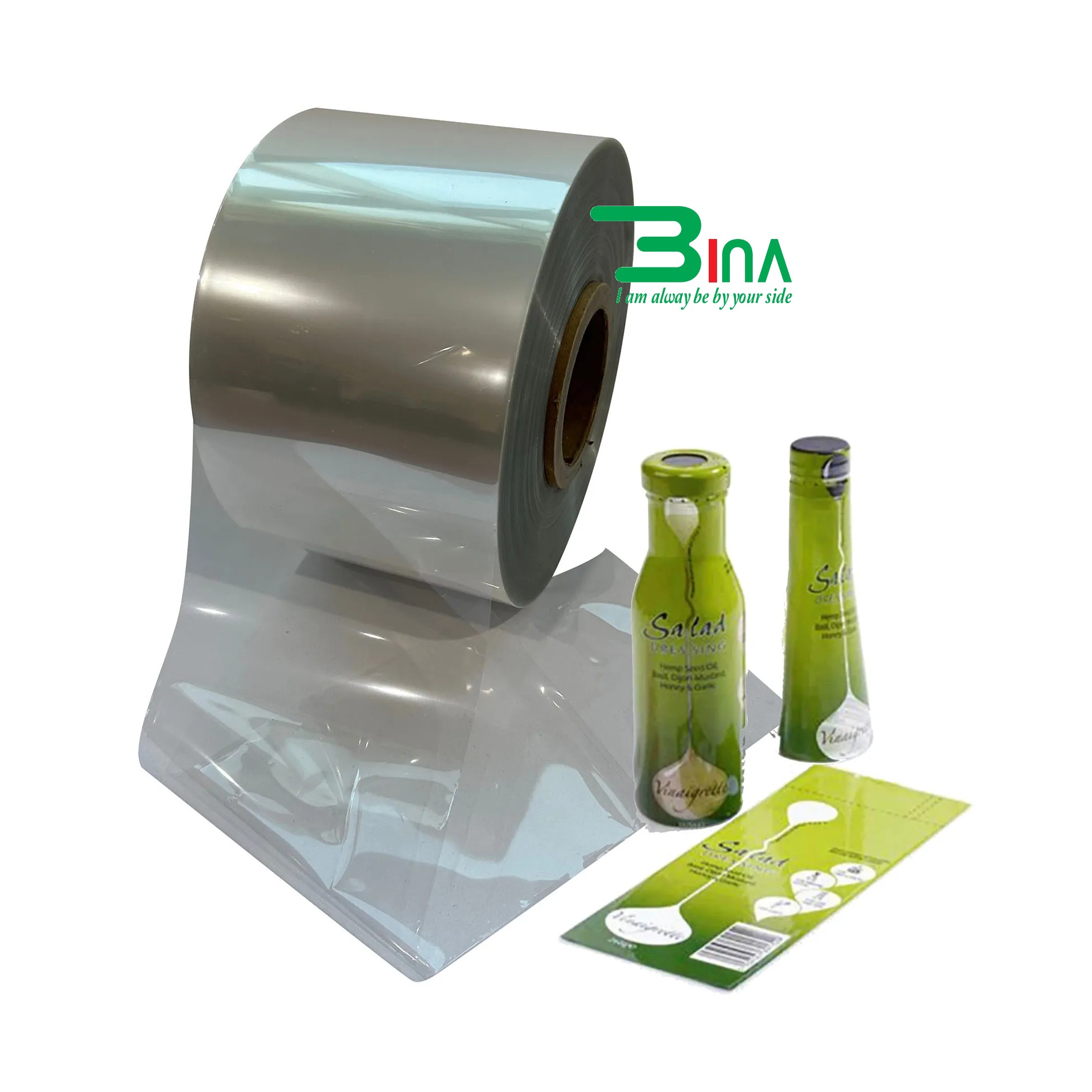

| 200 gauge | PVC | Màng phim cứng, bền với khả năng chống rách và đâm thủng tuyệt vời. Độ trong tương đối | 300°-325° F | 25%-35% | Dán quanh chai và ống co nhiệt |

| 2-20 Mil | Polyethylene hoặc Polypropylene | Phim chịu lực có thể dao động từ độ trong suốt khá đến không có | 300°+ F | 20% trở xuống | Ứng dụng chịu lực từ chai nước đến thuyền và tòa nhà |

Câu hỏi thường gặp về màng co nhiệt

Màng co nhiệt dùng để làm gì?

Màng co nhiệt là thuật ngữ chung có thể dùng để chỉ nhiều loại vật liệu. Màng co để bọc pallet hàng hóa thường được gọi là màng co nhiệt. Màng co nhiệt là một loại vật liệu khác co lại khi chịu nhiệt, thường được dùng để bảo vệ các sản phẩm thương mại, bán lẻ và cá nhân. Cả hai đều cần thiết để ngăn ngừa hư hỏng hoặc mất mát sản phẩm.

Bạn có thể tự làm màng co nhiệt không?

Có, bạn có thể tự làm màng co nhiệt với các vật dụng gia đình hàng ngày, nhưng vẻ ngoài hoàn thiện không chuyên nghiệp bằng. Túi màng co nhiệt PVC và máy sấy tóc sẽ co lại quanh sản phẩm. Dán băng keo trước khi dùng nhiệt có thể giúp vá màng co lại với nhau. Vẻ ngoài hoàn thiện sẽ không sạch như chất bịt kín, nhưng màng co sẽ bám chặt vào sản phẩm. Chúng tôi khuyên bạn nên mua máy bịt kín, súng nhiệt và túi co nhiệt để bọc nhiều sản phẩm hơn một số ít.

Sự khác biệt giữa màng bọc nhựa và màng co nhiệt là gì?

Màng bọc nhựa và màng co nhiệt là những thuật ngữ mơ hồ dùng để chỉ nhiều loại vật liệu khác nhau. Màng bọc nhựa có thể là màng bọc thực phẩm nhà bếp, màng căng, giấy bóng kính và các vật liệu khác. Màng co nhiệt cũng có thể là một số vật liệu như vậy. Màng co nhiệt khác với tất cả các vật liệu khác do có các chất phụ gia được sử dụng trong quá trình đùn. Các chất phụ gia đó cho phép hợp chất hóa học của vật liệu co lại khi nhiệt được áp dụng mà không bị tan chảy qua nhựa.

Màng co nhiệt có giống với màng bọc thực phẩm không?

Mặc dù cả hai đều có thể được làm từ các hợp chất tương đương, nhưng màng co nhiệt có các chất phụ gia đặc biệt để co lại khi nhiệt được áp dụng. PVC từng được ưa chuộng trong cả màng bọc thực phẩm và màng co nhiệt. Trong những năm gần đây, polyolefin đã trở thành vật liệu được ưa chuộng trong màng co nhiệt. Không áp dụng nhiệt vào màng bọc thực phẩm; nó sẽ tan chảy.

|

Tôi đo màng co nhiệt như thế nào?

Đo màng co nhiệt tương đối đơn giản nhưng được xác định bởi loại sản phẩm co nhiệt mà bạn định sử dụng. Xem bên dưới để biết công thức đo lường cho mọi loại màng. Hãy nhớ rằng, nếu không có kích thước chính xác cần thiết, hãy chuyển sang kích thước tiếp theo. Tất cả các loại màng co nhiệt của chúng tôi đều có tỷ lệ co ít nhất là 30%.

- Công thức đo màng co ở giữa: Chiều rộng + Chiều sâu x 2 x 1,1÷2 = Chiều rộng màng co ở giữa cần thiết

- Công thức đo túi co: Công thức tương tự như trên để xác định chiều rộng túi, đối với chiều dài, hãy thêm 1-2 inch để có đủ chỗ để tạo lớp niêm phong.

- Công thức đo ống co: Đối với các vật thể hình vuông, hãy sử dụng cùng công thức như trên, nhưng hầu hết mọi người sử dụng ống cho mục đích hình trụ. Nếu đo cho vật thể hình tròn, hãy sử dụng phương trình bên dưới. Chu vi x 2 x 1,1÷2 = Chiều rộng ống cần thiết

Khi nào tôi sử dụng màng co và khi nào tôi sử dụng màng co?

Màng co thường được sử dụng để bảo vệ và đóng gói một sản phẩm duy nhất, như đồ chơi hoặc đĩa CD. Nó cũng được sử dụng để giúp bó nhiều sản phẩm lại với nhau. Nó được sử dụng để bó soda, chai nước và nhiều sản phẩm đóng gói khác lại với nhau. Thông thường, màng co được sử dụng để giữ các hộp và sản phẩm lại với nhau trên một pallet để vận chuyển. Nó cũng có thể được sử dụng để giữ các vật thể khác lại với nhau để vận chuyển hoặc lưu trữ. Màng co giãn có thể có nhiều loại màng chuyên dụng. Một số ví dụ là màng co giãn UV, màng quấn pallet có lỗ thông hơi, màng co giãn chống tĩnh điện, màng co giãn màu, màng co giãn đã kéo căng trước, v.v. Màng co giãn và màng co giãn có thể tái chế được không? Cả màng co giãn và màng co giãn đều có thể tái chế được. Kiểm tra với trung tâm tái chế tại địa phương của bạn và đảm bảo rằng họ chấp nhận nhựa mềm.

Tôi có cần một máy co màng cụ thể không?

Các ứng dụng khác nhau đòi hỏi máy móc. Khi sử dụng màng co, cần có dụng cụ gia nhiệt để co màng. Có nhiều loại thiết bị để sử dụng, tùy thuộc vào mục đích bạn muốn đạt được. Các công cụ thông thường là súng nhiệt, máy dán L-Bar, máy dán I-Bar và đường hầm co màng.

Máy co màng có cắt và dán màng co cùng một lúc không?

Có, hầu hết các máy dán màng co đều cắt và dán màng co trong một chuyển động. Sau khi dán và cắt, có thể bóc các mảnh vụn ra và có thể áp dụng nhiệt vào màng co. Nhiệt sẽ làm giảm kích thước của màng co và giúp màng co phù hợp với sản phẩm.

Máy sấy tóc có thể thay thế súng nhiệt cho màng co không?

Súng nhiệt cho màng co Không, nếu bạn muốn có vẻ ngoài chuyên nghiệp, bạn nên sử dụng súng nhiệt. Màng co cần đạt nhiệt độ 300 độ F để co màng đúng cách. Súng nhiệt cho màng co rất phải chăng.

Tôi cần loại màng co nào?

Chúng tôi khuyên dùng màng co 75 cho các sản phẩm dưới 12 pound. Màng co 100 được khuyên dùng cho các sản phẩm có trọng lượng lên đến 30 pound. Để xem biểu đồ chuyển đổi kích thước của chúng tôi, hãy nhấp vào đây.

Túi màng co là gì?

Túi co là loại túi được đo sẵn, thường được làm từ màng co PVC và có nhiều kích cỡ khác nhau. Chúng có khả năng đặt một hoặc nhiều sản phẩm vào bên trong túi để đóng gói nhanh chóng và an toàn. Túi co được sử dụng để đóng gói nhiều loại sản phẩm khác nhau, bao gồm CD, DVD, giỏ quà, các sản phẩm hỗn hợp, v.v. Nếu bạn đang đóng gói các sản phẩm sẽ tiếp xúc trực tiếp với thực phẩm, thì cần phải có túi polyolefin.

Tôi đo ống màng co như thế nào?

Bắt đầu bằng cách đo chu vi của vật thể sẽ được quấn màng co. Sau khi xác định được chu vi, hãy cộng thêm 10% vào chu vi. Chia số cuối cùng cho hai và con số đó sẽ là chiều rộng của ống màng co mà bạn cần. Nếu không có sẵn chiều rộng của ống co nhiệt cần thiết, bạn có thể sử dụng kích thước lớn hơn. Ống co nhiệt PVC có thể co lại tới 40% — xem: Cách đo ống co nhiệt.

Tôi đo túi co nhiệt như thế nào?

Đo sản phẩm được quấn co nhiệt xung quanh điểm rộng nhất của sản phẩm. Cộng thêm 10% vào chu vi đó và chia số đó cho hai. Con số này sẽ cho bạn biết chiều rộng của túi co nhiệt mà bạn cần. Tiếp theo, đo sản phẩm cần quấn co nhiệt xung quanh từ trên xuống dưới. Khi đã xác định được con số đó, hãy cộng thêm 10% rồi chia cho hai. Con số này sẽ cho bạn biết chiều dài của túi co nhiệt cần thiết.

|

Thuật ngữ phổ biến về màng co nhiệt

- Màng co nhiệt gấp đôi theo chiều dọc: Màng được gấp đôi theo chiều dọc để việc đóng gói dễ dàng và nhanh hơn.

- Chân chim: Nếp nhăn phân kỳ ra từ các góc của gói hàng đã hoàn thiện

- Tai chó: Các phần nhô ra hình tam giác của màng chưa co ở các góc của gói hàng hoàn chỉnh. Phổ biến trong các gói hàng được bọc bằng màng co nhiệt PVC.

- Đo lường: Một phép đo được sử dụng để mô tả độ dày của màng. Một thước đo bằng .254 Micron. Xem biểu đồ chuyển đổi thước đo của chúng tôi để biết thêm thông tin chi tiết.

- Máy hàn xung: Một máy hàn sử dụng một bộ phận gia nhiệt được xung điện áp trong quá trình hàn. Nhiệt từ máy hàn sẽ hàn gắn các vật liệu polyme lại với nhau.

- Máy hàn thanh chữ L: Một máy hàn có bề mặt hàn có hình chữ “L” ngược. Một máy hàn đa năng dành cho những người muốn hàn nhanh hơn so với máy hàn xung.

- Hàn chồng: Làm mối hàn bằng cách sử dụng hai lớp màng co chồng lên nhau.

- Hướng máy: Hướng màng được sản xuất và di chuyển qua thiết bị hàn.

- Bộ nhớ: Khả năng của màng co để duy trì các đặc tính sau khi niêm phong

- Quang học: Các đặc tính trực quan của màng co hoặc màng căng.

- Polyolefin: Một loại polyme được sản xuất từ olefin đơn giản (còn gọi là anken với công thức chung là CnH2n) dưới dạng monome. Màng co được làm từ loại này và thường được gọi là màng co POF.

- PVC: Polyvinyl Clorua, là một loại polyme nhiệt dẻo, là loại nhựa được sản xuất nhiều thứ ba trên thế giới. Màng co PVC là màng co phổ biến được sử dụng cho nhiều ứng dụng khác nhau.

- Đường hầm co: Thiết bị sử dụng buồng để tạo nhiệt với băng tải liên tục chạy qua buồng.

- Khả năng chống rách: Khả năng của màng chống rách khi tác động lực mạnh lên màng. Sử dụng màng co có khả năng chống rách cao hơn là điều quan trọng khi bọc các sản phẩm nặng hoặc các sản phẩm có cạnh sắc.

|

Các ngành công nghiệp thường sử dụng màng co nhiệt

- Đồ chơi & Đồ thể thao: Các nhà sản xuất, đại lý bán lẻ, nhà bán buôn và nhà bán lẻ thường sử dụng màng co để đóng gói nhiều loại hàng hóa và sản phẩm. Màng co PVC thường được sử dụng cho các mặt hàng này. Nó giúp tránh va chạm và phát hiện sự giả mạo và là một hình thức đóng gói giá cả phải chăng.

- In ấn & Sản phẩm giấy: Nhiều công ty trong ngành này sử dụng màng co để bảo vệ sản phẩm và hàng hóa của họ, tránh va chạm và phát hiện sự giả mạo. Thực phẩm – Một trong những ngành công nghiệp lớn nhất thường sử dụng màng co. Việc đóng gói bằng màng co giúp loại bỏ tiếp xúc oxy với thực phẩm và có thể giảm thiểu chất thải. Màng co POF (Polyolefin) là màng co thông thường được sử dụng để đóng gói thực phẩm. Hãy đảm bảo rằng màng co POF bạn chọn được FDA chấp thuận để tiếp xúc với thực phẩm.

- Thực phẩm đóng gói co: Thực phẩm – Một trong những ngành công nghiệp lớn nhất thường sử dụng màng co. Việc đóng gói bằng màng co giúp loại bỏ tiếp xúc oxy với thực phẩm và có thể giảm thiểu chất thải. Màng co POF (Polyolefin) là màng co tiêu chuẩn được sử dụng để đóng gói thực phẩm. Hãy đảm bảo màng co POF mà bạn chọn được FDA chấp thuận cho tiếp xúc với thực phẩm.

- Đồ kim khí & Đồ gia dụng: Nhiều nhà sản xuất và nhà bán lẻ trong các ngành này thường sử dụng màng co để tránh và phát hiện sự giả mạo. Họ cũng thường sử dụng màng co để bó nhiều sản phẩm lại với nhau.

- Điện tử: Ngành điện tử thường sử dụng ống co và màng co. Ống co được sử dụng trong điện tử để chống mài mòn và bảo vệ môi trường cho dây điện hở trong nhiều thành phần khác nhau. Họ cũng thường sử dụng túi co PVC và màng co PVC gấp giữa để đóng gói nhiều loại sản phẩm trong các ngành dưới đây.

- Dược phẩm: Ngành này sử dụng màng co để giúp niêm phong nắp và có khả năng phát hiện sự giả mạo.

- Lặt vặt: Có nhiều ngành công nghiệp và công dụng khác nhau của màng co. Ngành hàng hải thường sử dụng màng co để bảo vệ thuyền khỏi các yếu tố môi trường và chống đông.

|

-

Các vấn đề phổ biến khi bọc màng co nhiệt

- Nếp nhăn: Một trong những vấn đề phổ biến nhất mà các công ty mới sử dụng màng co gặp phải. Các đường kẻ trên màng co sau khi được làm nóng, cần phải làm nóng màng nhiều hơn. Nếu sử dụng súng bọc màng co, hãy làm nóng nhiều hơn ở các vùng nhăn. Nếu sử dụng đường hầm nhiệt, hãy làm chậm tốc độ băng tải hoặc tăng nhiệt độ.

- Tai chó: Màng co bị tụ lại ở các góc của gói hàng. Một vấn đề phổ biến khác khi bọc màng co. Tai chó sẽ xảy ra ở hầu hết mọi gói hàng được bọc màng co, nhưng có thể ngăn ngừa tình trạng tai chó quá mức bằng cách làm nóng nhiều hơn cho màng co.

- Bong bóng: Không khí dư thừa bị kẹt bên trong màng co đã được niêm phong. Bong bóng xảy ra sau khi các miếng dán được tạo ra và nhiệt được áp dụng. Thật khó để xác định sản phẩm nào sẽ bị bong bóng. Nếu gặp phải tình trạng bong bóng, có thể sử dụng các lỗ thông hơi nhỏ bằng kim để ngăn ngừa tình trạng bong bóng trong tương lai. Chúng tôi bán các cuộn và túi màng co có lỗ để ngăn ngừa tình trạng bong bóng.

- Lỗ cháy: Lỗ cháy là khi quá nhiều nhiệt được áp dụng cho màng co đang sử dụng. Nếu sử dụng súng nhiệt, hãy lùi súng nhiệt ra xa sản phẩm hơn. Nếu sử dụng đường hầm co, hãy tăng tốc băng tải hoặc giảm nhiệt.

- Rách màng co: Rách màng co thường do loại màng co đang sử dụng hoặc độ dày của màng co đang sử dụng. Nếu bị rách, hãy cân nhắc sử dụng màng dày hơn hoặc áp dụng một loại màng khác. Nếu sử dụng PVC, hãy chuyển sang polyolefin hoặc polyethylene.

Đánh giá

Chưa có đánh giá nào.