Mô tả

Màng căng PE co giãn cần thiết trong mọi ngành công nghiệp

Nhiều sản phẩm của nhiều ngành công nghiệp khác nhau có thể bị hư hỏng trong quá trình vận chuyển. Màng căng PE co giãn giúp giữ chặt hàng hóa tại chỗ và bảo vệ hàng hóa khỏi mọi hư hỏng có thể xảy ra. Điều này khiến màng co giãn trở thành loại vật liệu đóng gói được sử dụng rộng rãi nhất. Những loại nylon đàn hồi này là giải pháp đơn giản nhưng hiệu quả để đóng gói sản phẩm đúng cách.

|

|

|

Màng co giãn là gì?

Màng co giãn là một loại màng bọc nhựa co giãn được sử dụng để đóng gói sản phẩm nhằm giữ chặt sản phẩm tại chỗ. Màng co giãn tương tự như giấy bóng kính dùng trong nhà bếp, điểm khác biệt là màng co giãn nặng và có lớp phủ chắc chắn để giữ chặt sản phẩm tại chỗ.

|

|

|

Loại màng phủ này có thể dễ dàng sử dụng cho nhiều loại hàng hóa có hình dạng và kích thước khác nhau. Nó rất nhanh và dễ mở. Ngoài ra, bạn có thể dễ dàng giảm thể tích đóng gói càng nhiều càng tốt để tiết kiệm không gian. Lớp bọc này được mở bằng tay và sau khi mở, bạn có thể tái chế để tái sử dụng. Vật liệu phổ biến nhất cho màng căng là polyethylene mật độ thấp tuyến tính, được sản xuất bằng cách đồng trùng hợp ethylene với alpha-olefin.

|

|

|

Màng căng PE polyethylene được sử dụng ở đâu?

Xem xét rằng màng căng được cung cấp trên thị trường với nhiều lớp khác nhau, chúng có thể đáp ứng được kỳ vọng của các doanh nghiệp khác nhau về việc đóng gói các sản phẩm khác nhau. Những màng polyethylene này được sử dụng trong việc đóng gói các sản phẩm thực phẩm, sản phẩm chăm sóc sức khỏe, nông nghiệp, xây dựng và nhiều trường hợp khác.

Vì những màng căng này được đặt trên sản phẩm, chúng tôi sử dụng chúng khi chúng tôi có ý định ngăn chặn ngay cả bụi bẩn và độ ẩm xâm nhập vào sản phẩm. Một trong những công dụng quan trọng nhất của màng căng là trong vận chuyển đến những nơi rất xa. Do khả năng chống chịu và hiệu quả cao của màng căng, nên sản phẩm hiếm khi bị hư hỏng.

|

|

|

Các loại màng căng do Hadupack sản xuất tại Hà Nội

Màng căng có nhiều loại khác nhau để đáp ứng nhiều nhu cầu đóng gói khác nhau. Ví dụ, màng căng có khả năng chống tia UV có các chất phụ gia hóa học trung hòa ánh sáng. Trong trường hợp các mặt hàng được bọc ở ngoài trời và tiếp xúc với thời tiết khắc nghiệt và các yếu tố môi trường khác như ánh sáng mặt trời, các chất phụ gia này cung cấp khả năng bảo vệ tối ưu. Trong phân loại chung, chúng có thể được chia thành các loại sau:

- Màng căng máy: Màng căng máy được sử dụng để đóng gói và bảo vệ các sản phẩm cần được thực hiện bằng máy móc. Tất nhiên, cần phải nói rằng những màng căng máy gắn trên máy này cũng có các loại khác nhau.

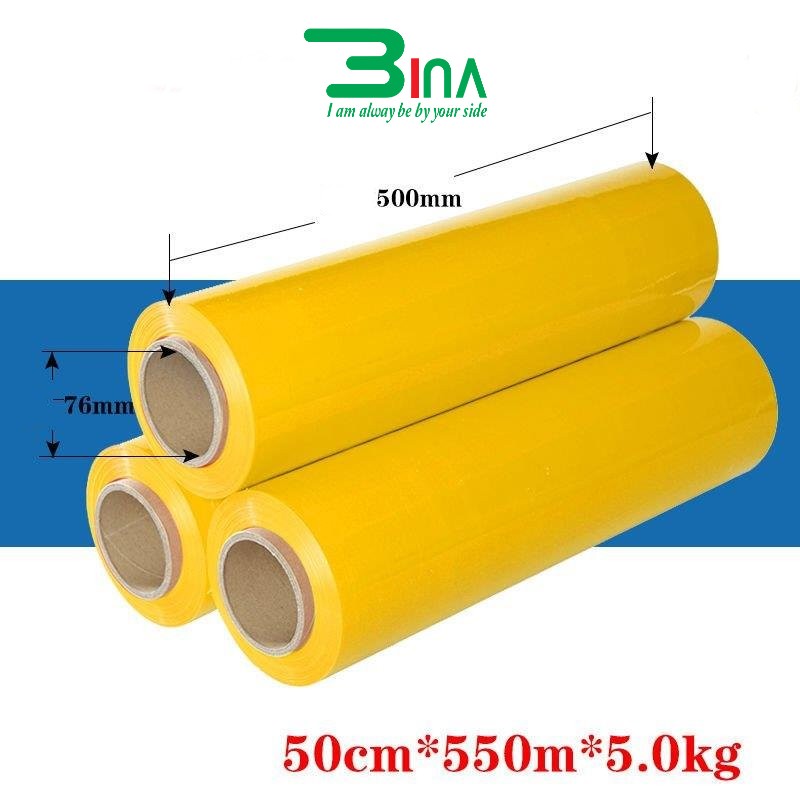

- Màng căng thủ công: Loại màng căng này được sử dụng khi chúng ta có kế hoạch đóng gói sản phẩm thủ công. Độ dày của màng căng thủ công nằm trong khoảng từ 17 đến 30 micromet. Chiều dài và chiều rộng của màng căng này được đo và cắt với độ chính xác cao.

|

|

|

Màng căng polyetylen có đặc điểm gì?

Trong số các đặc điểm rất quan trọng của màng căng polyetylen là chúng rất bền. Bên cạnh đó, chúng cũng rất linh hoạt. Mặt khác, chúng không thấm ẩm. Vì lý do này, màng căng rất hiệu quả.

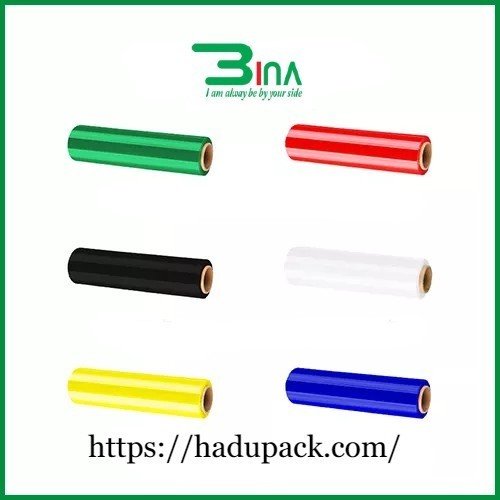

Bạn có thể nghĩ rằng mặc dù có những ưu điểm này, màng căng có giá cao, nhưng chúng có giá thấp hơn nhiều so với các mặt hàng tương tự. Bạn có thể đặt hàng màng căng với nhiều màu sắc và kích cỡ khác nhau theo nhu cầu của mình, hoàn toàn phụ thuộc vào nhu cầu của khách hàng.

Ngoài ra, màng căng polyethylene cũng có thể được đặt hàng với nhiều độ dày khác nhau. Ví dụ, màng căng dùng cho thực phẩm, màng căng dùng trong xây dựng và màng căng dùng cho ô tô hoàn toàn khác nhau. Bạn có thể thay đổi độ dày và đặt hàng số lớp theo nhu cầu của mình. Do tất cả các tiện ích và tính năng này, màng căng polyethylene rất được nhiều người ưa chuộng. Các tính năng khác của màng căng polyethylene như sau:

|

|

|

- Loại: kéo thủ công và kéo máy

- Ứng dụng: đóng gói pallet thủ công hoặc máy, đóng pallet dễ dàng bằng cuộn ngắn và nhẹ, bảo vệ hàng hóa lâu dài

- Tăng độ bền của bao bì để bảo mật tốt hơn khi vận chuyển và lưu trữ hàng hóa

- Tăng cường quản lý hàng tồn kho trong kho

- Khả năng chống đâm thủng cao do cấu trúc nhiều lớp

- Độ phân giải cao để kiểm tra sản phẩm

- Bảo vệ chống trượt

Loại màng này có những đặc điểm độc đáo giúp nó phù hợp với những ứng dụng cụ thể, bao gồm đảm bảo độ bền của bao bì để tăng cường tính bảo mật và vận chuyển, lưu trữ hàng hóa, tăng cường tính bảo mật và quản lý hàng tồn kho, khả năng chống đâm thủng cao do cấu trúc nhiều lớp, độ phân giải cao để kiểm tra sản phẩm, chống tia UV và bảo vệ chống trượt.

Đánh giá

Chưa có đánh giá nào.