Mô tả

Hạt nhựa LLDPE là gì?

Hạt nhựa LLDPE là copolymer ethylene-butene được sản xuất bằng quy trình pha khí áp suất thấp với khả năng gia công và tính chất cơ học tốt. Chúng chủ yếu được sử dụng cho các ứng dụng đùn màng như túi chịu lực nặng, màng căng, màng bọc ngoài và màng nông nghiệp cũng như ứng dụng đúc quay cho bể chứa nước, thùng chứa công nghiệp và rào chắn giao thông.

◆Tìm hiểu thêm:

- https://hadupack.com/san-pham/hat-nhua-gpps/

- https://hadupack.com/san-pham/hat-nhua-hdpe/

- https://hadupack.com/san-pham/hat-nhua-hips/

Tính chất:

- Dễ hàn & khả năng gia công bằng máy

- Ép nhiệt tốt

- Khả năng chống ăn mòn cao

- Hấp thụ độ ẩm thấp

- Khả năng chống mài mòn tốt

- Tính chất cách điện

- Độ bền cao

- Độ giãn dài khi đứt cao

- Có thể sử dụng ở nhiệt độ từ -50°C đến + 85°C

- Không hấp thụ nước

Thông số kỹ thuật:

1. Lớp màng LLDPE

| Đơn vị | giá trị | thử nghiệm |

| Tốc độ dòng chảy nóng chảy (MFR) | 2.0±0.4 | g/10min |

| Tỉ trọng | 920±2 | Kg/cm3 |

| Độ bền kéo tại giới hạn chảy | 8 | Mpa ≥ |

| Độ bền kéo khi đứt | 12 | Mpa ≥ |

| sương mù | 15 | %≤ |

3. Cấp đúc quay bột LLDPE dùng cho bể chứa

| Đơn vị | giá trị | thử nghiệm |

| Tốc độ chảy chảy (MFR) | 3.2 | g/10min |

| Mật độ | 0.939 | g/cm3 |

| Điểm nóng chảy | 127 | C |

| Độ bền kéo đứt | 21 | Mpa |

| Độ bền kéo đứt | 28 | Mpa |

| Độ giãn dài đứt | 1,100 | % |

| Mô đun uốn | 750 | Mpa |

| Nhiệt độ giòn | <-60 | C |

2. LLDPE dùng cho Master Batch

| Kiểm tra | giá trị | thử nghiệm |

| Tốc độ chảy chảy (MFR) | 20 | g/10min |

| Mật độ | 0.924 | g/cm3 |

| Độ bền kéo | MD12 | Mpa |

| Độ bền kéo | TD 10 | Mpa |

| Độ giãn dài khi giới hạn chảy | 13 | % |

| Độ giãn dài khi đứt | 200 | % |

| Độ va đập khi rơi tối | 105 | g |

| Nhiệt độ giòn | -70 | c |

| Điểm làm mềm Vicat | 90 | c |

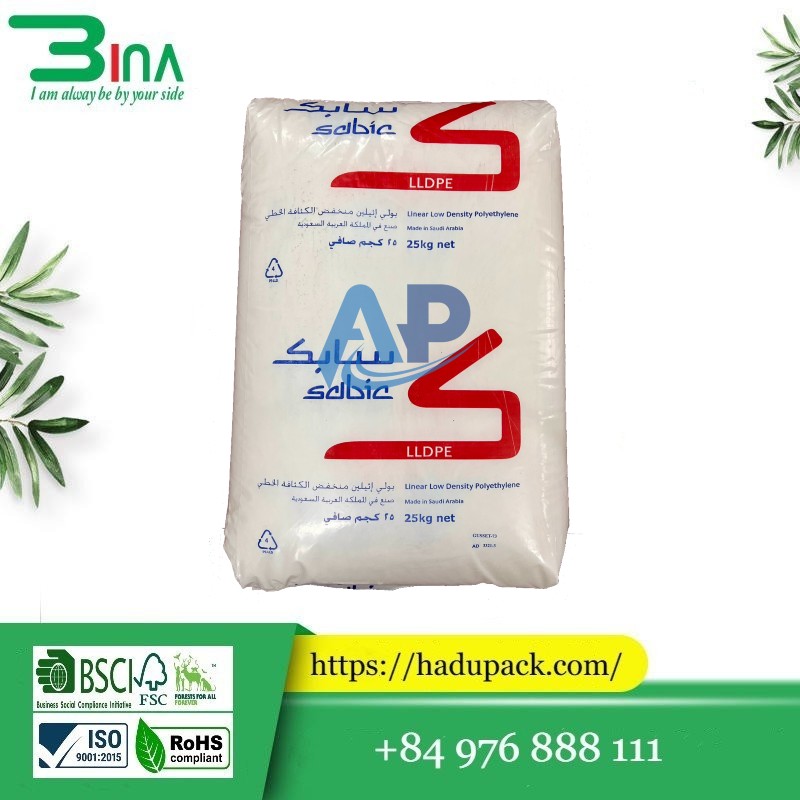

Đóng gói:

Trong bao dệt PP 25kg, hoặc theo yêu cầu của bạn. 17-20mt/20’FCL 24-28mt/40’FCL

2. Bảo quản:

Nhựa phải được bảo quản trong kho khô ráo, thoáng gió, tránh xa lửa và ánh nắng trực tiếp. Không được chất đống ngoài trời.

3. Vận chuyển:

Trong quá trình vận chuyển, không được để sản phẩm tiếp xúc với ánh nắng mạnh hoặc mưa và không được vận chuyển cùng với cát, đất, phế liệu kim loại, than hoặc thủy tinh. Nghiêm cấm vận chuyển cùng với chất độc hại, ăn mòn và dễ cháy.

Đánh giá

Chưa có đánh giá nào.