Mô tả

Túi xốp PE foam là gì?

Túi xốp PE foam là giải pháp đóng gói nhẹ, cung cấp lớp đệm bảo vệ xung quanh sản phẩm của bạn. Được làm từ polyethylene, túi xốp của chúng tôi cung cấp mức độ bảo vệ cao nhất để tạo ra một gói vận chuyển hiệu quả cao. Túi xốp lý tưởng để bảo vệ các sản phẩm dễ vỡ dễ bị trầy xước trong quá trình vận chuyển, chẳng hạn như các sản phẩm sơn hoặc thủy tinh.

|

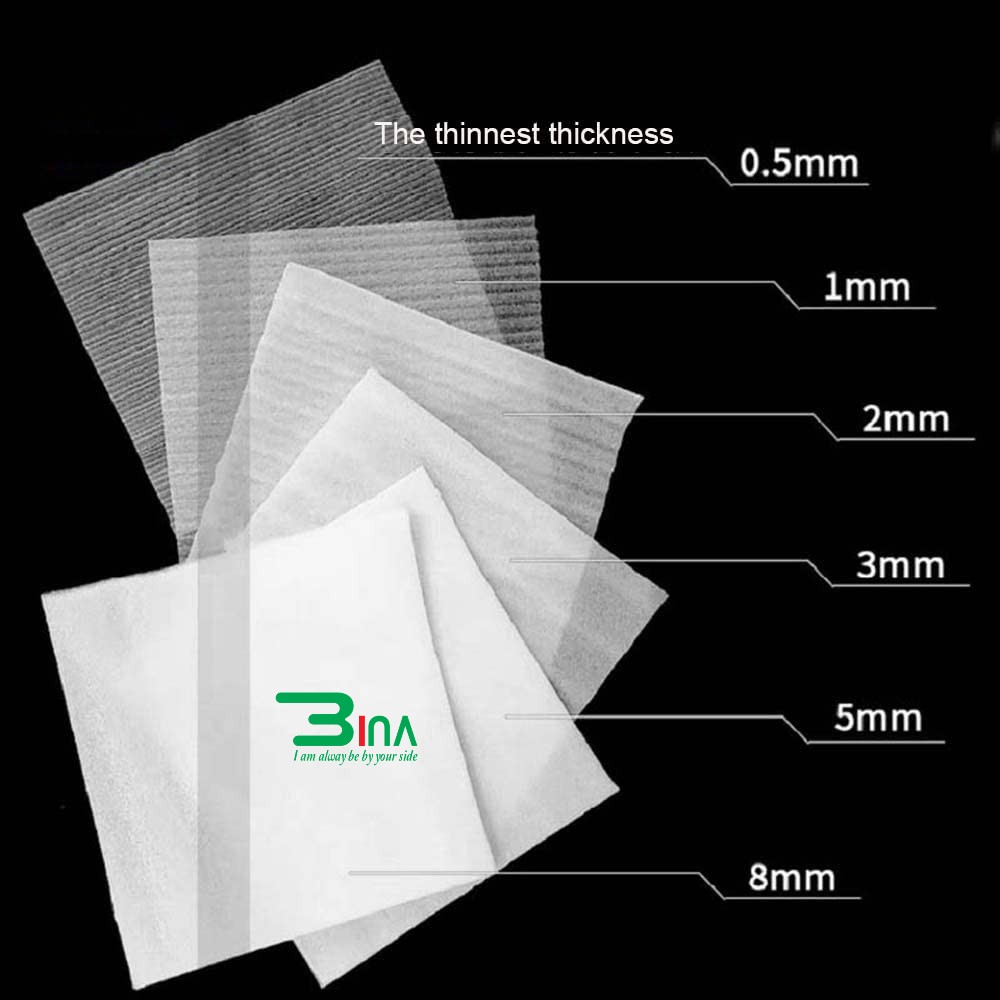

Túi xốp nhanh chóng và dễ sử dụng và có thể thêm các dải tự niêm phong để tăng hiệu quả đóng gói. Điều này có thể tiết kiệm thời gian đóng gói quý giá nếu bạn đang cắt và dán các tấm xốp rời. Chúng tôi cung cấp nhiều độ dày xốp và sẽ đề xuất mật độ tối ưu dựa trên yêu cầu về hiệu suất và các biến số của chuỗi cung ứng của bạn.

|

Để nâng cao khả năng trình bày sản phẩm, túi xốp có thể được cung cấp với nhiều màu sắc khác nhau. Chúng tôi cũng cung cấp túi xốp in, tạo cơ hội để truyền đạt và quảng bá bất kỳ thông tin về thương hiệu hoặc sản phẩm nào. Vì túi xốp nhẹ nên chúng cũng giúp giảm thiểu chi phí vận chuyển và lượng khí thải carbon.

|

Hiệu quả túi xốp PE foam

- Bao bì bảo vệ mềm và nhẹ

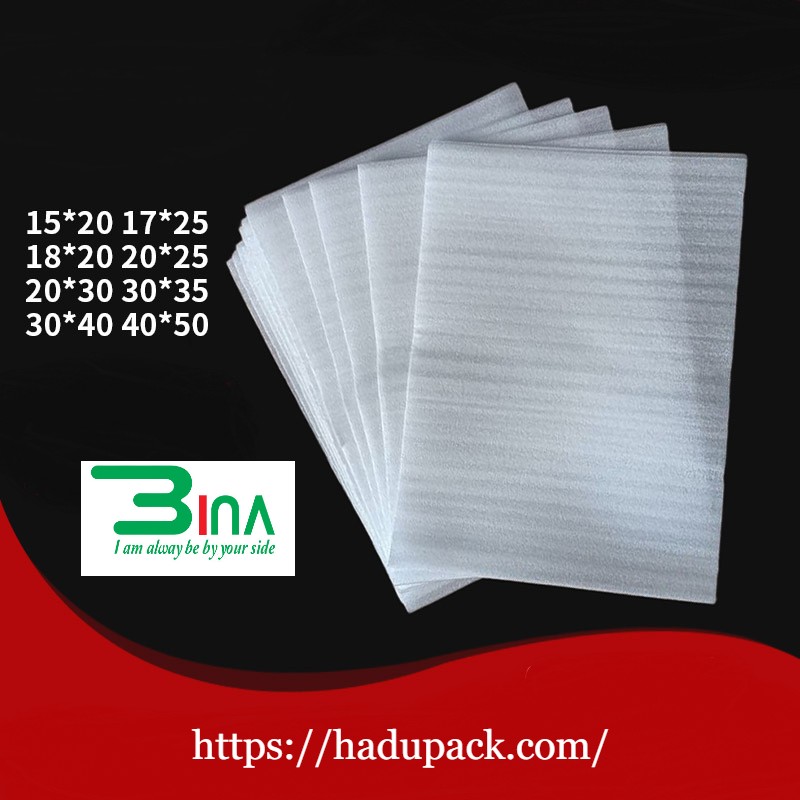

- Nhiều kích cỡ có sẵn trong kho, sẵn sàng giao hàng ngay

- Bảo vệ khỏi bụi, ẩm và trầy xước

- Tiết kiệm khi đặt hàng số lượng lớn với mức chiết khấu số lượng nổi tiếng của chúng tôi!

- Túi xốp có mép gấp 30mm

- Có thể tái chế và tái sử dụng

|

Những túi xốp này cung cấp khả năng bảo vệ mềm mại, không mài mòn cho các mặt hàng mỏng manh và dễ bị trầy xước hoặc bị đánh dấu của bạn. Được làm từ xốp polyethylene 1,5mm, chúng là một trong những lựa chọn đóng gói nhẹ nhàng nhất hiện có trên thị trường và cũng sẽ cung cấp khả năng bảo vệ đáng tin cậy và lâu dài khỏi bụi và độ ẩm. Xốp là vật liệu đóng gói cực kỳ nhẹ và lý tưởng để bảo vệ kính, gốm sứ, gỗ, crôm và bề mặt sơn. Có nhiều kích cỡ có sẵn ngay từ kho, mỗi kích cỡ có mép gấp 30mm.

Kích thước tiêu chuẩn: 4 x 6″; 6 x 9″; 8 x 10″; 9 x 12″; 10 x 13″; 12 x 15″

Đánh giá

Chưa có đánh giá nào.