Mô tả

Túi chống tĩnh điện là gì, chúng hoạt động như thế nào?

Túi chống tĩnh điện ngăn cản điện tích bằng cách giúp chống lại và kiểm soát phóng tĩnh điện – dòng electron tích điện đột ngột giữa các vật thể khác nhau. Có nhiều loại túi khác nhau với các mức độ bảo vệ khác nhau. Điều quan trọng là phải hiểu được sự khác biệt và chọn loại túi phù hợp với nhu cầu của bạn.

|

Rất nhiều linh kiện điện tử rất nhạy cảm và có nguy cơ bị hư hỏng khi xảy ra hiện tượng phóng tĩnh điện. Tĩnh điện này có thể gây hư hỏng lớn cho mạch điện bên trong của các linh kiện hoặc bộ vi xử lý khiến chúng trở nên vô dụng hoặc “bị cháy”.

|

|

Tích điện do ma sát là yếu tố phổ biến nhất gây ra sự tích tụ tĩnh điện. Chúng ta có thể định nghĩa tích điện do ma sát là một dạng nhiễm điện tiếp xúc, đây là nơi các vật liệu có thể bị tích điện khi chúng tiếp xúc ma sát với một vật liệu khác.

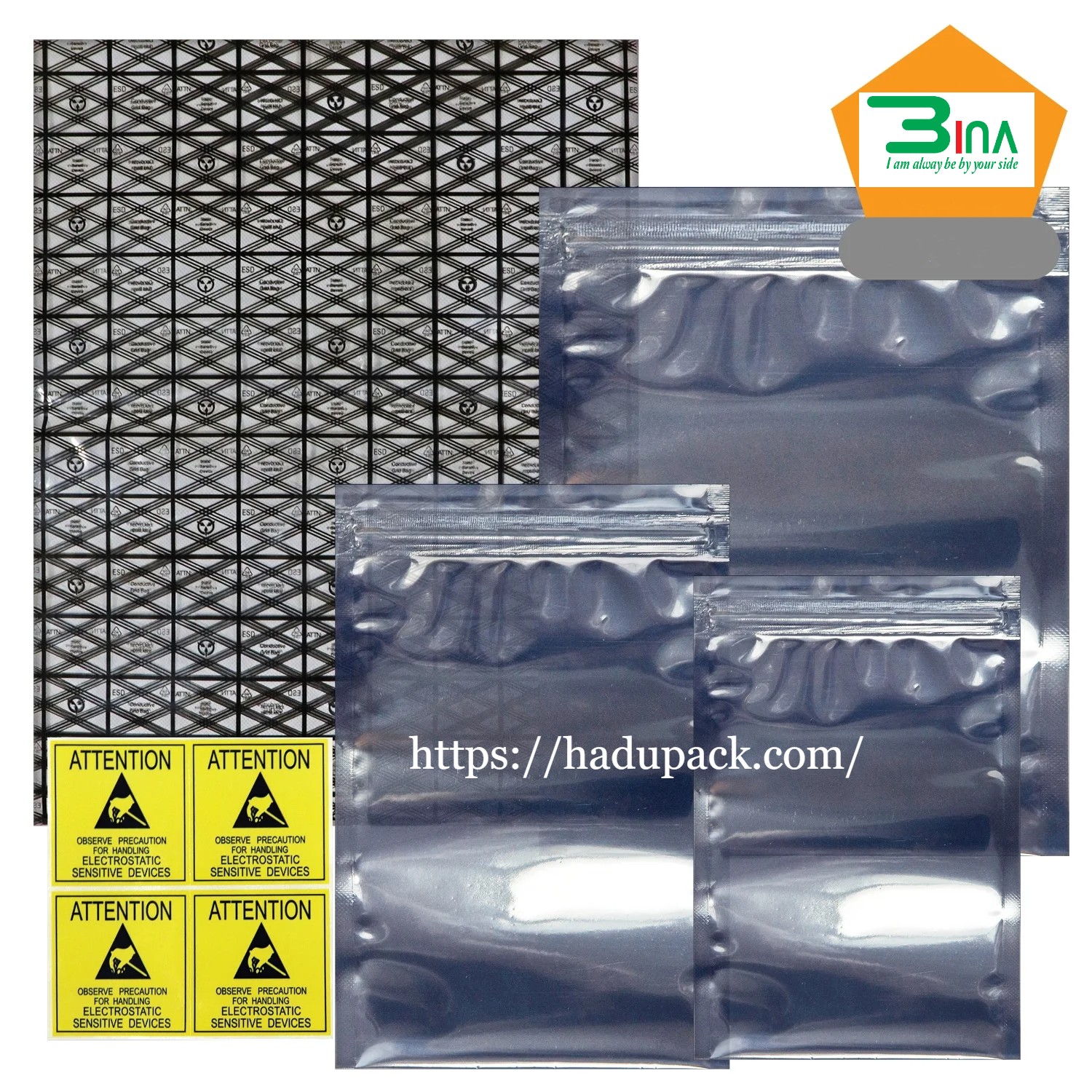

Để ngăn các linh kiện của chúng ta bị hư hỏng, chúng ta sử dụng túi chống tĩnh điện để giúp bảo vệ chúng khỏi hiện tượng này. Hai loại túi chống tĩnh điện phổ biến nhất được sử dụng là túi chống tĩnh điện phân tán và túi chống tĩnh điện, tuy nhiên, hầu hết mọi người sẽ chỉ gọi chúng bằng thuật ngữ chung là “túi chống tĩnh điện”.

|

|

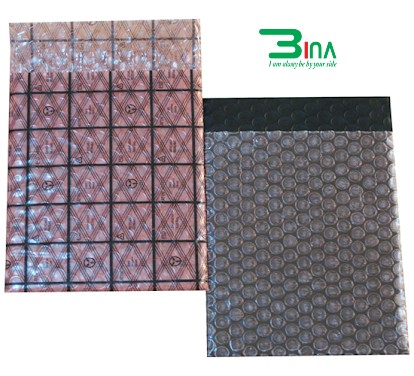

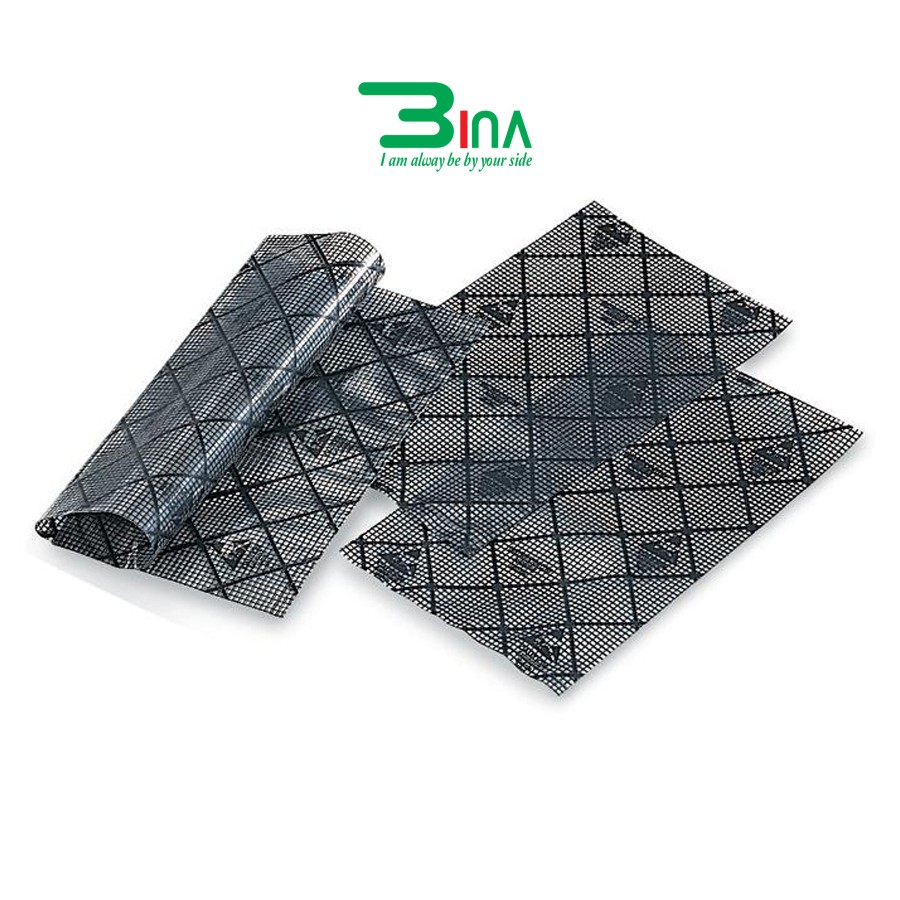

Túi chống tĩnh điện PE phân tán:

Những loại túi này được làm từ vật liệu nhựa polyethylene thường có màu hồng hoặc đen. Nhựa polyethylene không tạo ra hoặc giữ bất kỳ dạng điện tích nào, điều này có nghĩa là nếu đồ bên trong túi di chuyển hoặc bất kỳ thứ gì bên ngoài cọ xát vào nó, hiệu ứng tích điện ma sát sẽ không xảy ra nên không tạo ra điện tích tĩnh.

|

|

Trong quá trình vận chuyển đồ điện tử, nhựa polyethylene không chỉ được sử dụng làm túi. Nhựa polyethylene cũng được sử dụng để tạo ra màng bọc bong bóng polyethylene và bọt poly để tăng thêm lớp bảo vệ trong bao bì.

Tuy nhiên, trong khi những chiếc túi này có hiệu quả trong việc ngăn ngừa sự tích tụ tĩnh điện, chúng sẽ không bảo vệ các linh kiện điện tử khỏi sự phóng tĩnh điện trực tiếp nên chỉ được sử dụng trên các linh kiện không thể bị hư hỏng do sự phóng tĩnh điện, nhưng có thể được mang vào môi trường mà sự tích tụ của sự phóng tĩnh điện có thể ảnh hưởng đến các linh kiện nhạy cảm hơn.

|

|

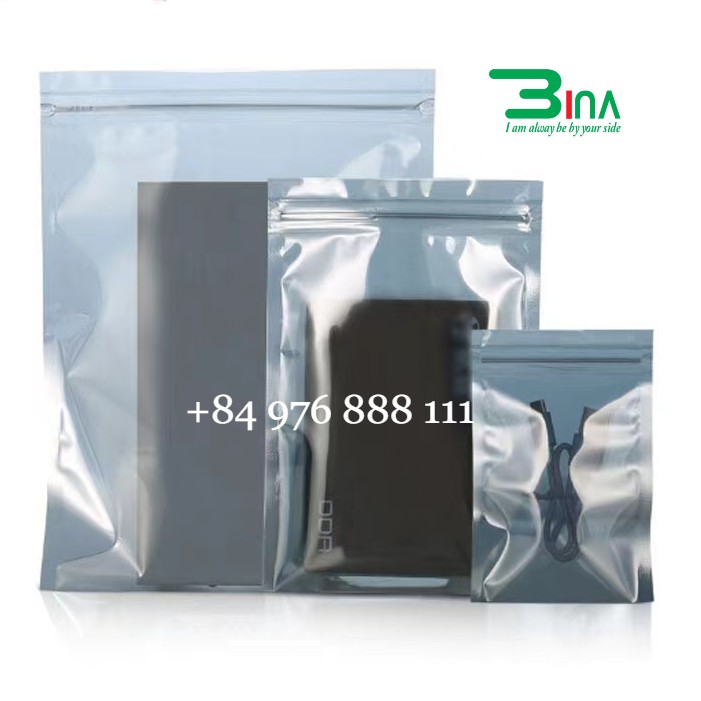

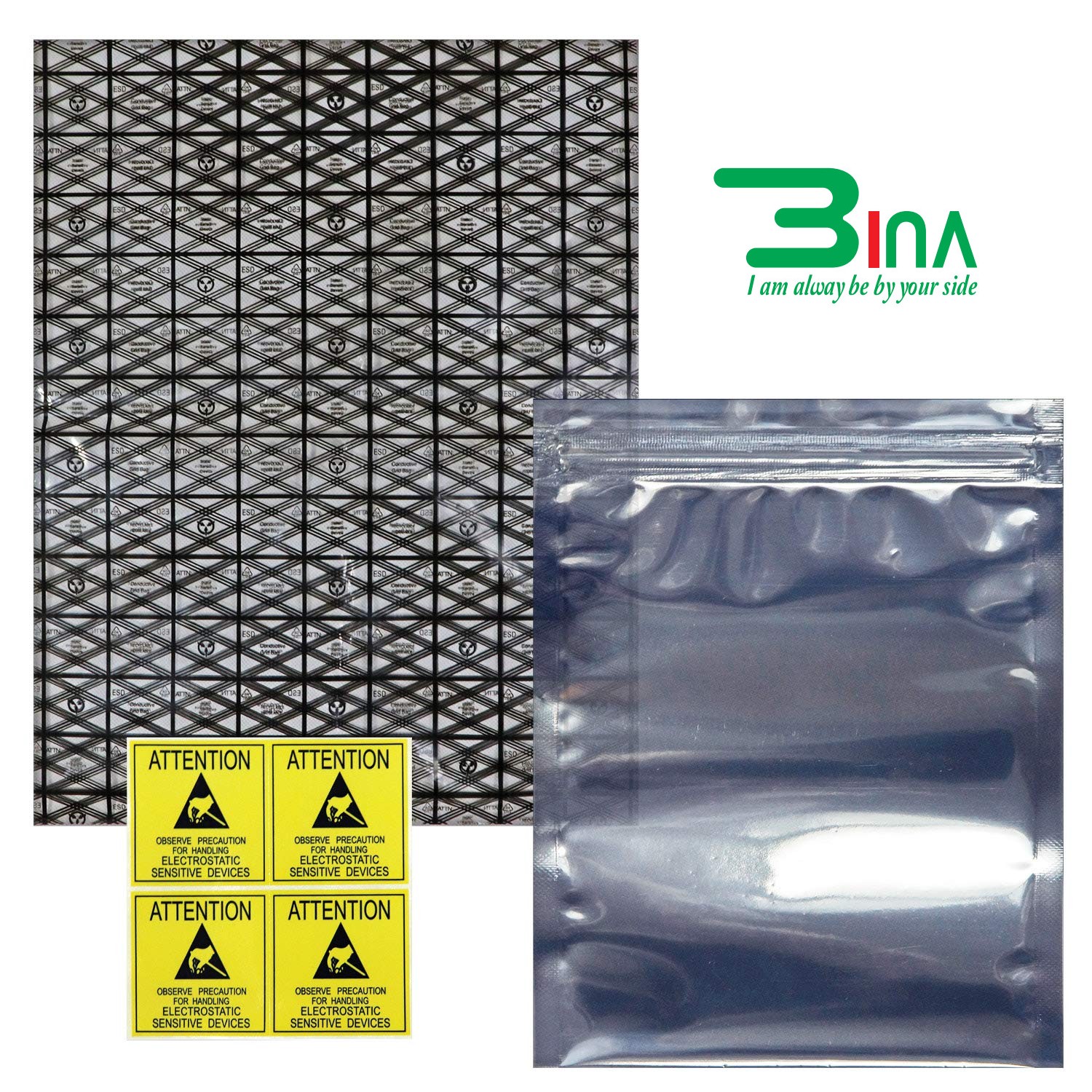

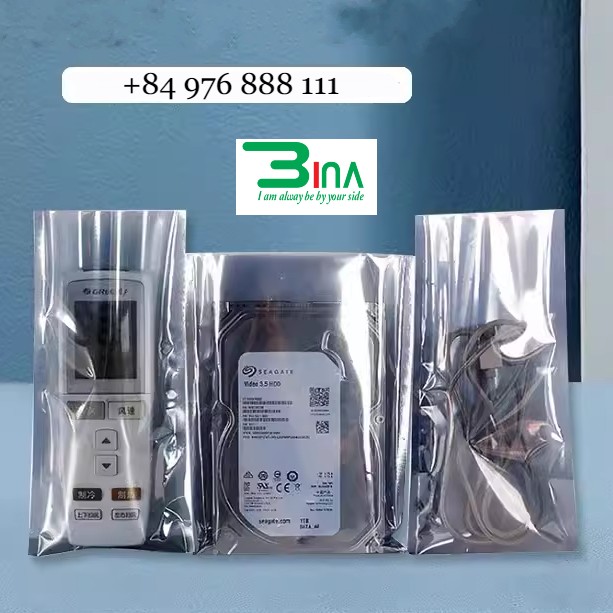

Túi chống tĩnh điện ESD nhiều lớp:

Được tạo thành từ nhiều lớp vật liệu khác nhau, những chiếc túi này nặng hơn và cồng kềnh hơn so với túi chống tĩnh điện tản nhiệt. Túi chống tĩnh điện mô phỏng hiệu ứng lồng Faraday cho các thiết bị điện tử bên trong chúng, bảo vệ hoàn toàn chúng khỏi sự phóng tĩnh điện trực tiếp và tích tụ tĩnh điện. Túi chống tĩnh điện được sử dụng cho các thiết bị điện tử nhạy cảm có thể bị hư hỏng do sự phóng tĩnh điện.

|

|

- Lớp đầu tiên (bên trong) của chiếc túi này được tạo thành từ cùng một loại nhựa polyethylene tản nhiệt như túi chống tĩnh điện, tạo ra một lớp mềm để linh kiện điện tử nằm trên đó đồng thời ngăn ngừa sự tích tụ tĩnh điện có thể phát sinh do chuyển động của linh kiện bên trong.

- Lớp thứ hai (ở giữa) của chiếc túi này được làm bằng nhôm, tạo thành một lớp chắn chống lại sự phóng tĩnh điện, lớp này được sử dụng như một chất dẫn điện để tiếp nhận điện tích tĩnh trực tiếp một cách an toàn và nối đất, nghĩa là đồ vật bên trong túi vẫn an toàn.

- Lớp thứ ba (bên ngoài) của chiếc túi này được tạo thành từ một dạng polyester có lớp phủ tản nhiệt tương tự như lớp phủ trên nhựa polyethylene. Lớp này được sử dụng để thêm một lớp bảo vệ nữa cho chiếc túi và đồ vật bên trong vì nó giúp bảo vệ lớp giữa và ngăn chặn mọi sự tích tụ tĩnh điện ở bên ngoài túi.

|

|

Tìm nguồn cung cấp túi chống tĩnh điện

Khi tìm nguồn cung cấp túi chống tĩnh điện cho doanh nghiệp của bạn, có một số điểm chính cần lưu ý.

- Chất lượng của túi; mặc dù túi giá rẻ có vẻ hấp dẫn, nhưng có thể không phải là khoản đầu tư tốt nhất; đặc biệt là khi nói đến chất lượng túi. Khi tìm kiếm túi, hãy luôn kiểm tra chương trình chất lượng của nhà cung cấp, khả năng truy xuất nguồn gốc vật liệu và tiêu chuẩn thử nghiệm. Nhà sản xuất phải kiểm tra vật liệu và túi trước khi vận chuyển.

- Chuỗi cung ứng; tính ổn định và giao hàng.

- Các đặc tính kỹ thuật và thông số kỹ thuật.

- Tuân thủ các tiêu chuẩn; hãy xem xét Tiêu chuẩn quốc tế IEC 61340-1-5.

- Lựa chọn kích thước tiêu chuẩn.

- Khả năng tùy chỉnh; nếu đây là điều bạn yêu cầu.

- Cuối cùng là giá cả.

|

|

Bảo vệ các thành phần bằng bao bì túi chống tĩnh điện ESD

Mặc dù việc sử dụng các sản phẩm kiểm soát ESD, như bộ tiếp địa và dây đeo cổ tay ESD là điều quan trọng trong EPA, nhưng cũng cần cân nhắc cách vận chuyển các thành phần và thiết bị nhạy cảm với ESD mà không bị hư hỏng. May mắn thay, dòng sản phẩm túi chống tĩnh điện và bao bì chống tĩnh điện của chúng tôi giúp bạn dễ dàng tìm thấy vật tư vận chuyển và lưu trữ cần thiết cho bất kỳ thành phần nào. Đừng quên thêm biểu tượng cảnh báo vào không gian làm việc được EPA bảo vệ để nhắc nhở mọi người đeo dây đeo cổ tay chống tĩnh điện.

Để được tư vấn về túi chống tĩnh điện, hãy liên hệ với Hadupack. Để tìm hiểu thêm, hãy duyệt qua dòng sản phẩm túi chống tĩnh điện và túi chắn tĩnh điện của chúng tôi ngay trên trang web của chúng tôi, hãy liên hệ với nhóm thân thiện của chúng tôi theo số 0976 888 111 hoặc gửi email cho chúng tôi theo địa chỉ sales@binavietnam.com.

Đánh giá

Chưa có đánh giá nào.