Mô tả

Khám phá thế giới kỳ diệu của băng keo tesa – chuyên gia về chất kết dính chất lượng cao

Trong cuộc sống hiện đại, băng dính đã trở thành một trong những công cụ không thể thiếu của chúng ta. Cho dù đó là bảo trì nhà cửa, công việc văn phòng hay sản xuất công nghiệp, bạn đều có thể nhìn thấy. Trong số rất nhiều thương hiệu, băng keo tesa chắc chắn là một trong những nhà cung cấp băng keo đáng tin cậy nhất. Hôm nay, chúng ta sẽ khám phá sâu hơn về thương hiệu đến từ Đức này và tìm hiểu về những câu chuyện cũng như công nghệ tiên tiến đằng sau các sản phẩm của hãng.

|

◆Tìm hiểu thêm:

- https://hadupack.com/san-pham/bang-dinh-kraft/

- https://hadupack.com/san-pham/bang-dinh-nhom/

- https://hadupack.com/san-pham/bang-dinh-phan-quang/

Lịch sử và di sản của tesa

Tesa được thành lập vào năm 1894 và có trụ sở tại Hamburg, Đức. Là công ty gia đình có lịch sử hơn 100 năm, tesa luôn cam kết cung cấp các sản phẩm và dịch vụ chất lượng cao, thân thiện với môi trường. Trong những năm qua, công ty đã tạo được danh tiếng tốt trên toàn thế giới nhờ khả năng đổi mới vượt trội và không ngừng theo đuổi chất lượng sản phẩm.

|

Các loại và ứng dụng của băng keo tesa

Băng keo tesa nổi tiếng thế giới với nhiều ứng dụng đa dạng. Từ băng keo trong suốt thông thường đến băng keo công nghiệp chuyên nghiệp, dòng sản phẩm của tesa đáp ứng hầu hết mọi mục đích sử dụng có thể. Dưới đây là một số băng tesa phổ biến và ví dụ về ứng dụng của chúng:

- Băng trong suốt: Loại băng cơ bản nhất này phù hợp với nhiều tình huống khác nhau trong cuộc sống hàng ngày, chẳng hạn như đóng gói, sửa chữa, v.v.

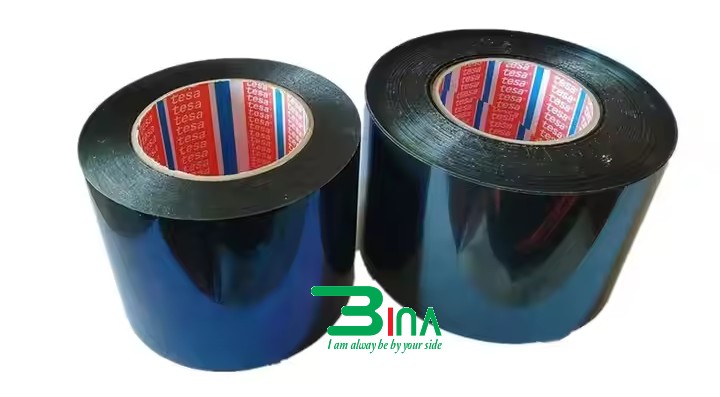

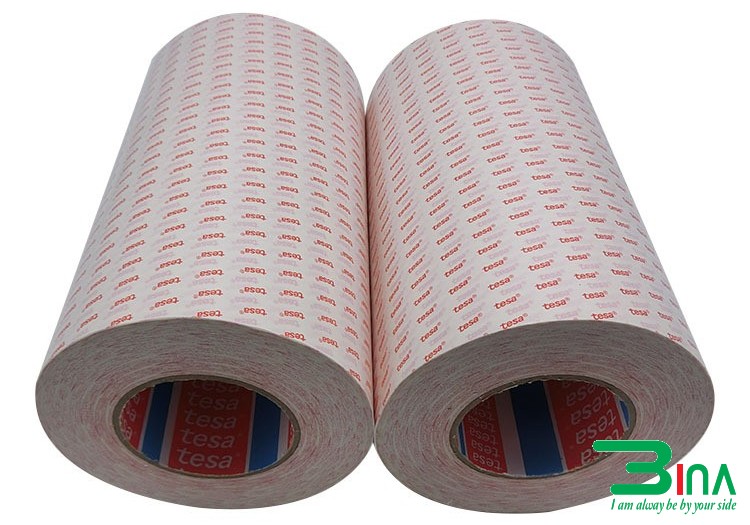

- Băng keo hai mặt: Loại băng keo có đặc tính kết dính ở cả hai mặt, thường được sử dụng để dán áp phích, ảnh và các vật dụng khác.

- Băng keo: có khả năng xé rách tốt và chống trơn trượt, thích hợp để đánh dấu và cố định giấy hoặc vải.

- Băng keo sợi thủy tinh: Được làm bằng sợi thủy tinh, bền và chịu được nhiệt độ cao, thích hợp để cách nhiệt trong các thiết bị điện tử.

- Băng chống thấm: Nó có đặc tính bịt kín và chống thấm tuyệt vời và có thể được sử dụng để chống thấm đường ống, bể chứa nước, v.v.

- Băng không dấu vết: Được thiết kế để dễ dàng gỡ bỏ mà không để lại dấu vết, lý tưởng để dán tạm thời hoặc trưng bày.

- Băng tiêu tán tĩnh điện: Nó có thể giải phóng tĩnh điện và ngăn chặn các sản phẩm điện tử bị hư hỏng do tĩnh điện.

|

Công nghệ tiên tiến của tesa Tape

Để đáp ứng nhu cầu thay đổi của thị trường, tesa tiếp tục đầu tư vào nghiên cứu, phát triển và phát triển một loạt sản phẩm băng keo cải tiến. Ví dụ, băng keo “thông minh” của công ty có thể tự động điều chỉnh độ nhớt theo nhiệt độ môi trường, giúp sử dụng thuận tiện và an toàn hơn. Ngoài ra, tesa còn tích cực quảng bá các ý tưởng bảo vệ môi trường và ra mắt hàng loạt sản phẩm băng keo làm từ vật liệu tái tạo.

|

Trải nghiệm và đánh giá của người dùng

Theo phản hồi của người dùng, trải nghiệm sử dụng băng keo tesa nhìn chung là tốt. Nhiều người tiêu dùng khen ngợi sản phẩm của hãng có chất lượng ổn định, dễ vận hành và khả năng ứng dụng mạnh mẽ. Đồng thời, một số chuyên gia cho rằng băng keo chuyên nghiệp của tesa có thể đóng vai trò quan trọng trong các môi trường phức tạp và giúp nâng cao hiệu quả công việc.

|

Phần kết luận về băng keo tesa

Qua phần giới thiệu trên, chúng ta có thể thấy băng keo tesa không chỉ là một công cụ mà còn là một giải pháp. Dù trong cuộc sống gia đình hay sản xuất công nghiệp, tesa đều có thể cung cấp các sản phẩm băng keo phù hợp để đáp ứng nhu cầu của nhiều người dùng khác nhau. Trong tương lai, với sự phát triển hơn nữa của công nghệ và sự mở rộng của thị trường, tôi tin rằng tesa sẽ tiếp tục dẫn đầu xu hướng phát triển của ngành băng keo và mang đến cho chúng ta nhiều bất ngờ hơn nữa.

Đánh giá

Chưa có đánh giá nào.