Mô tả

Vai trò và lợi ích túi PP (polypropylene)

Điều gì khiến túi nhựa PP polypropylene trở thành lựa chọn hàng đầu cho các doanh nghiệp trên toàn cầu? Câu trả lời nằm ở những đặc tính đáng chú ý và khả năng thích ứng với nhiều nhu cầu đóng gói khác nhau của chúng. Việc hiểu rõ đặc điểm, ứng dụng và lợi ích của túi polypropylene là rất quan trọng để đưa ra quyết định sáng suốt phù hợp với từng nhu cầu sản xuất khác nhau. Bài viết sau đây sẽ là chìa khóa mở ra góc nhìn chi tiết về các khía cạnh trên!

|

◆Tìm hiểu thêm:

- https://hadupack.com/san-pham/tui-opp/

- https://hadupack.com/san-pham/in-tui-nhua/

- https://hadupack.com/san-pham/tui-chong-gi/

1. Túi polypropylene là gì?

Túi polypropylene là sự lựa chọn phổ biến của người tiêu dùng trong nhiều lĩnh vực khác nhau của cuộc sống. Điều này là do tính chất bền, nhẹ và cực kỳ linh hoạt của chúng. Về mặt cấu trúc, túi polypropylene được sản xuất từ một loại polyme nhiệt dẻo gọi là polypropylene (PP). Về mặt tính chất, túi polypropylene pp có độ bền cao, khả năng chống hóa chất và khả năng chịu tải cực kỳ lý tưởng.

Các ứng dụng phổ biến của túi polypropylene bao gồm từ túi đựng ngũ cốc, phân bón, cát đến túi mua sắm. Trên thực tế, túi polypropylene tiết kiệm chi phí và thân thiện với môi trường do có thể tái chế.

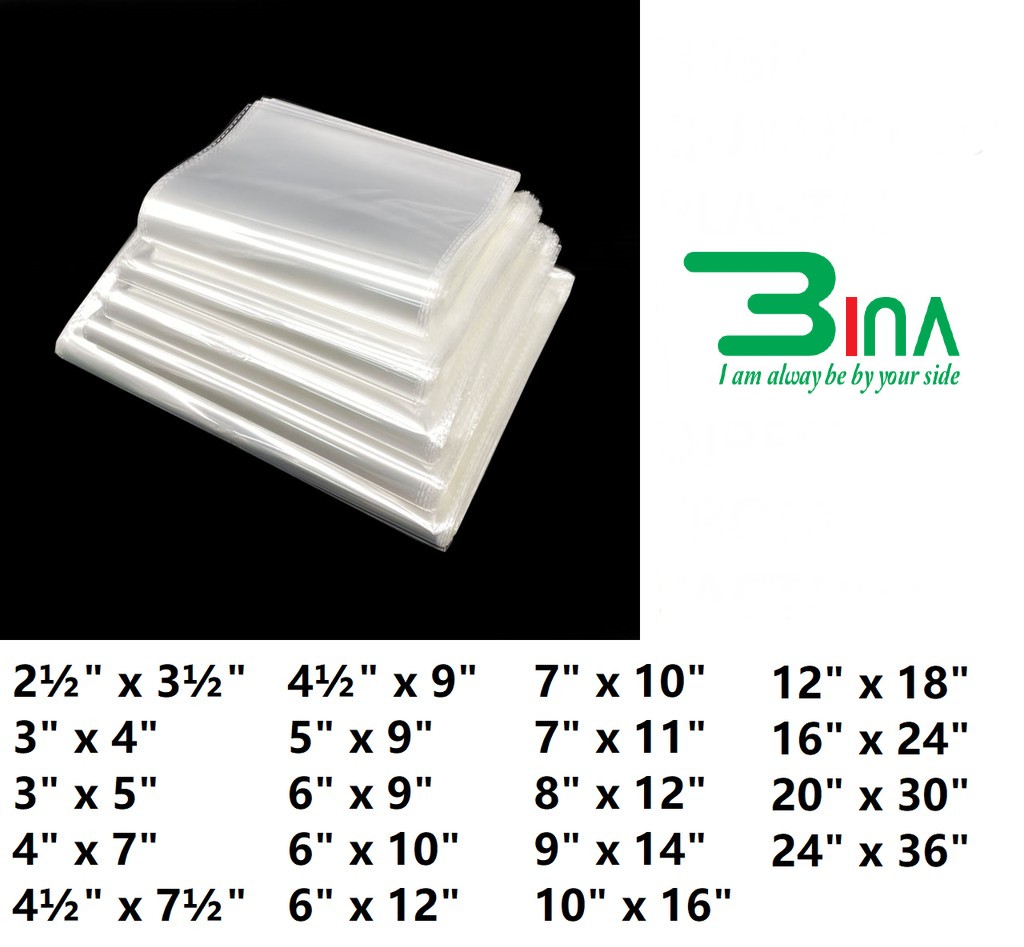

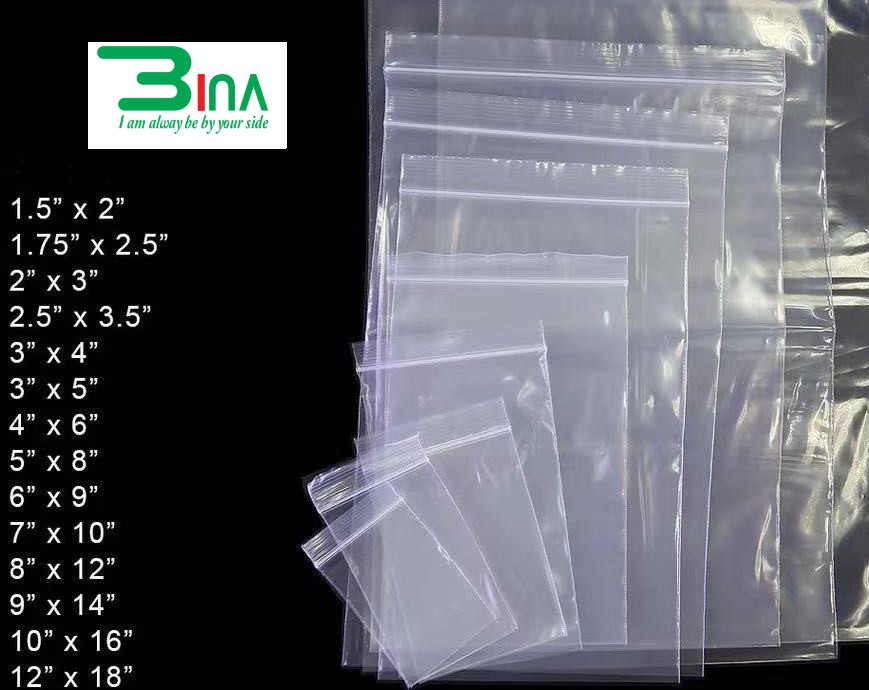

Ngoài ra, túi polypropylene cũng được coi là cực kỳ linh hoạt. Chúng có thể được sản xuất theo nhiều kích thước và kiểu dáng khác nhau, đảm bảo hiệu suất tối ưu và tính thẩm mỹ hấp dẫn cho người sử dụng.

|

2. Các loại túi nhựa PP polypropylene

Túi polypropylene là giải pháp tuyệt vời cho nhiều mục đích sử dụng. Trên thực tế, túi polypropylene cũng được chia thành nhiều loại khác nhau. Mỗi loại túi PP sẽ có những đặc điểm nổi bật riêng. Chúng ta hãy cùng khám phá một số biến thể phổ biến của túi polypropylene:

2.1. Túi polypropylene dệt

Túi polypropylene dệt được tạo ra bằng cách đan các sợi polypropylene lại với nhau. Do đó, những chiếc túi PP này sẽ được gia cố chắc chắn về mặt cấu trúc giúp chúng luôn bền và chắc. Túi polypropylene dệt được sử dụng để đóng gói các loại hàng hóa nặng như ngũ cốc, phân bón và vật liệu xây dựng.

|

|

2.2. Túi Polypropylene không dệt

Không giống như túi dệt, túi polypropylene không dệt được tạo ra bằng cách liên kết các sợi với nhau mà không cần dệt. Túi polypropylene được sản xuất theo cách này thường có ưu điểm là nhẹ. Một số loại túi PP không dệt mà chúng ta dễ dàng bắt gặp là túi mua sắm, túi đựng thực phẩm, v.v. Đặc biệt, chúng thường được tái sử dụng, khiến chúng trở thành lựa chọn thân thiện với môi trường phổ biến.

|

2.3. Túi BOPP (Biaxially Oriented Polypropylene)

Túi BOPP (Biaxially Oriented Polypropylene) là loại túi polypropylene được sản xuất thông qua bước kéo căng vật liệu theo hai hướng. Điều này giúp tăng độ bền và độ trong suốt của túi. Túi BOPP luôn là sự lựa chọn lý tưởng cho bao bì thương hiệu. Lý do chính là những chiếc túi pp polypropylene này có khả năng in chất lượng cao và cực kỳ linh hoạt trong thiết kế.

|

2.4. Túi FIBC (Flexible Intermediate Bulk Container)

Các vật liệu mà những túi Polypropylene này chứa thường là những vật liệu nặng như cát, hóa chất hoặc một số vật liệu xây dựng khác

Các vật liệu mà những túi Polypropylene này chứa thường là những vật liệu nặng như cát, hóa chất hoặc một số vật liệu xây dựng khác

Túi FIBC (Flexible Intermediate Bulk Container) được thiết kế để mang tải trọng nặng, thậm chí có thể chịu được tải trọng hơn một tấn. Túi FIBC thường được sử dụng để vận chuyển các vật liệu rời như cát, hóa chất và các vật liệu xây dựng khác.

|

3. Ưu điểm và nhược điểm của túi Polypropylene

Nhờ độ bền mà vẫn đảm bảo trọng lượng nhẹ, túi Polypropylene được sử dụng rộng rãi trong nhiều ngành công nghiệp khác nhau

3.1. Ưu điểm của túi Polypropylene (PP)

- Độ bền: Túi nhựa Polypropylene có cấu trúc chắc chắn, có khả năng chống mài mòn và rách cực tốt.

- Trọng lượng nhẹ: Nhờ độ bền mà vẫn đảm bảo trọng lượng nhẹ, túi Polypropylene (PP) được sử dụng rộng rãi trong nhiều ngành công nghiệp khác nhau. Điều này giúp chúng góp phần giảm chi phí vận chuyển và dễ dàng di chuyển.

- Khả năng chống ẩm: Khả năng chống ẩm của túi PP đã được ngành công nghiệp đóng gói thực phẩm chứng minh. Chúng giúp bảo quản thực phẩm khỏi bị hư hỏng và nấm mốc trong quá trình lưu trữ hoặc vận chuyển.

- Tính linh hoạt trong sản xuất: Túi polypropylen (PP) có thể được sản xuất với nhiều kiểu dáng, mẫu mã, màu sắc, hình ảnh và kích thước khác nhau để đáp ứng nhu cầu đóng gói đa dạng.

- Khả năng tái sử dụng và tái chế: Túi polypropylen được coi là một trong những giải pháp đóng gói thân thiện với môi trường nhất. Chúng có thể được tái sử dụng hoặc tái chế rất linh hoạt. Nhờ đó, túi polypropylen có độ bền cao, góp phần giảm thiểu lượng rác thải ra môi trường.

|

4.Ứng dụng phổ biến của túi Polypropylene (PP)

Nhờ độ bền, khả năng chịu tải cao và thân thiện với môi trường, túi nhựa polypropylene được sử dụng rộng rãi trong nhiều lĩnh vực khác nhau. Sau đây là một số lĩnh vực phổ biến mà túi PP vượt trội:

4.1. Nông nghiệp

- Nông nghiệp là một trong những ngành công nghiệp ghi nhận ứng dụng cao của túi polypropylene. Một số ứng dụng phổ biến của túi polypropylene trong lĩnh vực này bao gồm túi để lưu trữ và vận chuyển ngũ cốc, túi đựng hạt giống, thức ăn chăn nuôi, v.v.

- Túi polypropylene cung cấp cho ngành công nghiệp bao bì nông nghiệp khả năng chống ẩm, độ bền và sức chứa lớn tuyệt vời. Chúng góp phần bảo vệ các sản phẩm nông nghiệp khỏi nấm mốc, hư hỏng và ô nhiễm trong quá trình vận chuyển và lưu trữ.

4.2. Ngành xây dựng

Túi polypropylene là một trong những giải pháp lý tưởng để đóng gói và vận chuyển các vật liệu rời như cát, sỏi và xi măng. Chúng có sức chứa lớn và dễ dàng xử lý bằng các máy móc như xe nâng, xe kéo.

Hơn nữa, độ bền của túi PP đảm bảo rằng vật liệu xây dựng được bảo vệ an toàn, ngăn ngừa sự cố tràn và mất mát không cần thiết trong quá trình vận chuyển và lưu trữ.

4.3. Ngành bán lẻ

Từ túi mua sắm hàng ngày đến quà tặng khuyến mại, túi nhựa polypropylene cung cấp giải pháp tối ưu trong bán lẻ. Bản chất nhẹ, độ bền và khả năng tái sử dụng của chúng khiến túi PP trở thành sản phẩm được người tiêu dùng ưa chuộng.

Đối với các doanh nghiệp, nhiều công ty cũng tận dụng túi PP để quảng bá thương hiệu. Chúng rất linh hoạt nên thường được thiết kế với logo, màu sắc hoặc khẩu hiệu của các thương hiệu.

|

4.4. Ngành công nghiệp bao bì thực phẩm

- Túi polypropylen (PP) là lựa chọn hàng đầu để đóng gói đồ ăn nhẹ, bánh kẹo và thức ăn cho thú cưng, v.v. Người ta biết rằng túi polypropylen có chất lượng in cao, màu sắc tươi sáng và khả năng chống ẩm tốt, khiến chúng trở nên lý tưởng cho các ứng dụng bảo quản thực phẩm.

- Ngoài ra, do thiết kế bắt mắt, túi PP còn có tác dụng tích cực trong việc thu hút sự chú ý của người tiêu dùng. Túi polypropylen được coi là góp phần tiếp thị thương hiệu và tăng sức hấp dẫn của hàng hóa đóng gói.

4.5. Ngành công nghiệp hóa chất và phân bón

- Khả năng chống hóa chất mạnh của túi polypropylen khiến chúng trở nên lý tưởng để đóng gói và vận chuyển nhiều loại hóa chất và phân bón. Chúng góp phần bảo vệ các sản phẩm được chứa bên trong khỏi các yếu tố bên ngoài và bên trong.

- Túi polypropylen (PP) hoạt động bền bỉ trong môi trường hóa chất mà không bị mài mòn hoặc phân hủy. Ngoài ra, chúng còn giúp sản phẩm chống lại các tác động bên ngoài của môi trường như độ ẩm, tia UV, v.v.

5. Lựa chọn túi polypropylen (PP) phù hợp

Với nhiều loại túi polypropylene có sẵn, việc lựa chọn loại phù hợp với nhu cầu cụ thể của bạn là rất quan trọng. Sau đây là hai yếu tố chính cần cân nhắc:

- Trọng lượng và loại sản phẩm: Việc lựa chọn túi PP phù hợp bắt đầu bằng việc hiểu trọng lượng, kích thước, hình dạng và tính chất hóa học của sản phẩm. Đặc biệt, túi polypropylene không dệt thường phù hợp với các mặt hàng nhẹ. Ngược lại, nếu sản phẩm có kích thước lớn hoặc nặng, bạn cần cân nhắc các loại còn lại.

- Môi trường hoạt động: Chú ý đến các điều kiện môi trường mà túi sẽ tiếp xúc, chẳng hạn như độ ẩm, nhiệt độ và tia UV.

Một số môi trường hoạt động của túi polypropylene mà chúng ta cần cân nhắc là môi trường hóa chất mài mòn, môi trường ẩm ướt, môi trường ngoài trời, v.v. Hiểu được những thách thức về môi trường sẽ giúp bạn chọn loại túi bảo vệ hiệu quả các mặt hàng bên trong.

|

6. Tối ưu hóa sản xuất túi polypropylene với Masterbatch Filler PP

Masterbatch Filler PP là một trong những vật liệu nhựa phổ biến nhất trong sản xuất hiện nay. Chúng là hỗn hợp cô đặc của canxi cacbonat (CaCO₃) hoặc các chất độn khoáng khác, được phân tán trong nhựa mang polypropylene.

PP Filler Masterbatch là một trong những vật liệu đóng vai trò rất lớn trong sản xuất túi Polypropylene. Những lợi ích tuyệt vời mà chúng mang lại cho quy trình sản xuất túi PP có thể kể đến như:

- Tiết kiệm chi phí: Việc kết hợp PP Filler Masterbatch vào quy trình sản xuất sẽ giúp giảm lượng polypropylene nguyên chất cần thiết. Điều này giúp các nhà sản xuất tiết kiệm được một khoản chi phí đáng kể.

- Cải thiện tính chất cơ học: PP Filler Masterbatch giúp cải thiện độ cứng và độ bền kéo của túi polypropylene. Điều này giúp đảm bảo rằng túi polypropylene sẽ luôn đảm bảo hình dạng và tính toàn vẹn khi chịu áp suất hoặc tải trọng cao.

- Cải tiến trong sản xuất: PP Filler Masterbatch là một yếu tố quan trọng trong việc cải thiện quy trình tạo hình về mặt giảm co ngót, độ dày túi đồng đều hơn, bề mặt hoàn thiện mịn hơn và cải thiện độ ổn định của sản phẩm.

- Khả năng in được cải thiện: Vật liệu này cải thiện các đặc tính bề mặt của bao PP, giúp chúng dễ in hơn với chất lượng cao.

|

7. Câu hỏi thường gặp về túi Polypropylene (PP)

Túi polypropylene có phân hủy sinh học không?

Không, túi polypropylene không phân hủy sinh học. Chúng được làm từ vật liệu nhựa không phân hủy tự nhiên trong môi trường.

Túi polypropylene có thể tái chế không?

Có, túi polypropylene có thể tái chế. Chúng có thể được tái chế và sử dụng để tạo ra các sản phẩm nhựa mới, giúp giảm thiểu chất thải.

Túi nhựa có được làm từ polypropylene không?

Có, một số túi nhựa được làm từ polypropylene, đặc biệt là túi mua sắm có thể tái sử dụng và một số loại túi đóng gói.

Làm thế nào để biết một chiếc túi có phải là polypropylene không?

Bạn thường có thể nhận dạng túi polypropylene bằng mã tái chế của nó, thường được đánh dấu bằng số “5” hoặc “PP”. Vật liệu này cũng bền, hơi cứng và chống nước và hóa chất.

|

8. Kết luận về túi PP

Tóm lại, vai trò thiết yếu của túi polypropylene trong cuộc sống con người là không thể phủ nhận. Túi polypropylene (PP) hoàn toàn xứng đáng với danh hiệu vật liệu ưu tú vì độ bền, đặc tính nhẹ và khả năng chống chịu tuyệt vời với các yếu tố môi trường. Bằng cách sử dụng và tái chế túi polypropylene, họ cũng góp phần giảm thiểu chất thải ra môi trường. Bằng cách hiểu các loại túi polypropylene khác nhau và những lợi ích cụ thể của chúng, các doanh nghiệp có thể đưa ra những kế hoạch tuyệt vời cho chiến lược sản xuất của mình. Đây là một bước quan trọng trong việc tối ưu hóa chi phí sản xuất và hiệu suất sản phẩm.

Đánh giá

Chưa có đánh giá nào.