Mô tả

Hạt nhựa PBT là gì?

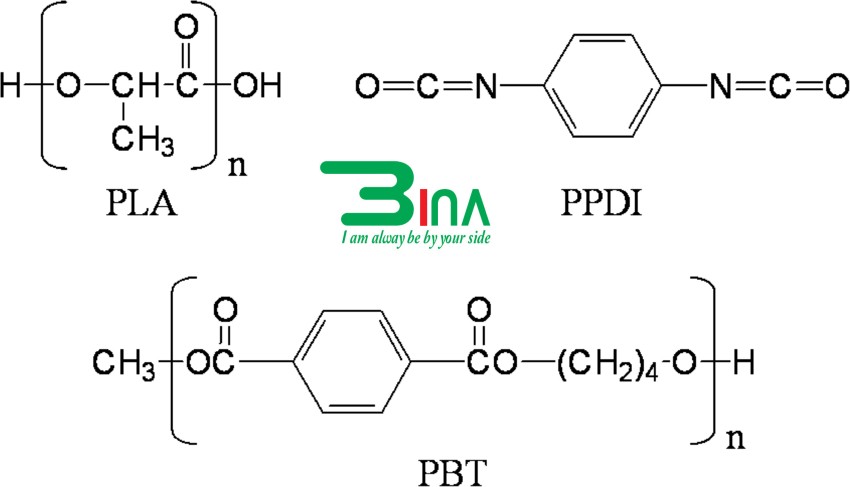

Hạt nhựa PBT (polybutylene terephthalate) là nhựa kỹ thuật nhiệt dẻo gốc polyester có tính chất điện và khả năng chống hóa chất tuyệt vời. Nhựa PBT được sản xuất từ nguyên liệu đầu vào chính là 1,4-butanediol và axit terephthalic và là nhựa polyester bão hòa nhiệt dẻo tuyến tính có liên kết este trong chuỗi chính.

Có thể dễ dàng tạo ra các tính năng độc đáo bằng cách kết hợp nhiều chất phụ gia, sợi thủy tinh, chất chống cháy và sử dụng các kỹ thuật hòa tan. Có nhiều loại để sử dụng. Hơn nữa, có thể dễ dàng thêm bất kỳ màu nào.

Sản phẩm được sử dụng trong nhiều ứng dụng trải dài trên nhiều lĩnh vực, bao gồm thiết bị điện và điện tử, đầu nối và vỏ tụ điện, thiết bị điện tử ô tô, thiết bị OA, vật liệu xây dựng và các bộ phận máy móc công nghiệp.

|

|

|

◆Tìm hiểu thêm:

- https://hadupack.com/san-pham/hat-nhua-pla/

- https://hadupack.com/san-pham/hat-nhua-pc/

- https://hadupack.com/san-pham/hat-nhua-tpe/

Tính năng hạt nhựa PBT

- Chất lượng chu kỳ cao dựa trên tốc độ kết tinh cao.

- Độ bóng bề mặt vượt trội.

- Độ ổn định kích thước vượt trội.

- Đặc tính chống mài mòn và chống mài mòn vượt trội.

- Khả năng chống hóa chất vượt trội.

- Tính chất điện tốt.

- Dễ dàng cải thiện các đặc tính với cốt sợi thủy tinh.

- Tính chất chống biến dạng và chống mỏi vượt trội.

- Có thể sử dụng liên tục ở nhiệt độ từ 120 đến 140°C.

- Dễ dàng tạo ra chất chống cháy.

- Hấp thụ nước thấp.

PBT bao gồm nhiều loại khác nhau rất phù hợp cho các quy trình như ép phun.

Các loại này bao gồm:

- ● Hiệu chỉnh va đập

- ● Làm đầy nâng cao

- ● Không cháy

Khi so sánh với nhựa không gia cường, độ bền kéo, uốn và nén và mô đun của PBT được gia cường bằng sợi thủy tinh tăng gấp hai đến ba lần. Hơn nữa, các loại PBT không được gia cường có phạm vi độ nhớt nóng chảy rộng. Điều này giúp cung cấp khả năng tự do xử lý lớn hơn cho công nghệ đùn và ép phun. Bao gồm sợi PBT được thổi nóng chảy và sản xuất ống sợi quang, thanh, tấm và lớp lót cáp phanh, ví dụ.

PBT có đặc tính chống cháy, cũng như các biến thể PBT được bôi trơn, cũng có thể được mua ở dạng không gia cố hoặc gia cố. Khi so sánh với nhựa không gia cố, cường độ nén, độ bền kéo, phạm vi uốn và mô đun của các loại được gia cố bằng sợi thủy tinh tăng gấp hai đến ba lần.

Hơn nữa, việc sử dụng rộng rãi PBT được phản ánh trong một số phê duyệt theo quy định ở nhiều cấp độ khác nhau. Các phê duyệt này bao gồm VDE và UL cho thị trường trong ngành điện và điện tử hoặc phê duyệt của FDA cho thị trường y tế và dinh dưỡng. Các phê duyệt như vậy chứng minh rõ ràng rằng PBT là một vật liệu đáng tin cậy.

Tính chất PBT

Polyme này cho thấy các tính chất cơ học và điện tuyệt vời, cũng như:

- ● PBT cung cấp các tính chất cơ học tuyệt vời để sử dụng trong thời gian ngắn, bao gồm độ dẻo dai, độ bền cao, độ cứng và độ va đập

- ● PBT có độ ổn định kích thước đáng khen ngợi, khả năng chống biến dạng và khả năng hấp thụ độ ẩm hạn chế

- ● PBT có thể sử dụng vật liệu hiệu quả để giảm cả chi phí và trọng lượng

- ● Các đặc tính gia công vượt trội

- ● Khả năng chống ố tuyệt vời

- ● Có độ bền tốt dưới ứng suất nhiệt và/hoặc môi trường hóa chất khắc nghiệt, đặc biệt là dưới mui xe

- ● Nhiệt độ biến dạng nhiệt cao và chỉ số nhiệt độ cao của PBT giúp các thành phần chịu được các biến động nhiệt ngắn hạn và tiếp xúc nhiệt dài hạn

- ● Khả năng chống biến dạng tốt ở nhiệt độ ổn định và cao

- ● Khả năng chống bức xạ cực tím tốt và hiệu suất lão hóa nhiệt tuyệt vời

- ● Tuân thủ các phê duyệt của nhiều cơ quan và cơ quan quản lý đối với các ứng dụng thực phẩm, y tế và nước uống, cũng như các thông số kỹ thuật về hiệu suất chuyên nghiệp

- ● Polybutylene terephthalate giúp bảo vệ các thành phần điện và điện tử, có khả năng chống chịu cực cao và sức mạnh điện môi và có thể ngăn ngừa rò rỉ và sự cố trong mạch điện

- ● Tổn thất điện môi thấp giúp giảm thiểu sự hấp thụ năng lượng trong các ứng dụng điện tử tần số cao

- ● Nếu cần, có thể cung cấp một loại chất chống cháy phù hợp

Như bạn thấy, PBT có rất nhiều đặc tính và phẩm chất thiết yếu mà các nhà sản xuất sẽ muốn lưu ý và sử dụng trong quá trình sản xuất các thành phần và sản phẩm khác nhau.

- Tuy nhiên, PBT có một số hạn chế đáng được đề cập. Đầu tiên, độ co ngót khuôn của nó khá cao. Điều này có nghĩa là nếu bạn sản xuất các bộ phận đúc phun, rất có khả năng chúng sẽ mất hình dạng và co lại theo thời gian.

- Hơn nữa, PBT rất nhạy cảm khi tiếp xúc với nước nóng. Ngoài ra còn có độ co ngót khác biệt mà bạn cần lưu ý, cũng như độ nhạy khía.

Tin tốt là PBT có khả năng chống lại nhiều loại hóa chất. Đây là một đặc tính rất quan trọng đối với các công ty sản xuất thiết bị hoặc bộ phận điện tử và ô tô. Khả năng chống chịu bao gồm các hóa chất như:

- ● Hydrocacbon thơm

- ● Axit loãng

- ● Dung môi

- ● Rượu

- ● Xeton

- ● Mỡ

- ● Dầu

Nếu bạn cần tạo ra một bộ phận nhựa sẽ tiếp xúc với bất kỳ loại hóa chất nào ở trên, PBT có thể là vật liệu tốt nhất cho nhu cầu của bạn. Sử dụng PBT sẽ đảm bảo hiệu suất lâu dài hơn cũng như hiệu suất cao.

Bất kỳ sự can thiệp nào từ nhiệt hoặc hóa chất đều có thể làm giảm đáng kể chất lượng hiệu suất của các bộ phận của bạn. Do đó, điều rất quan trọng là bạn phải chọn vật liệu phù hợp nhất với môi trường mà nó sẽ hoạt động.

Nếu cần, bạn luôn có thể sử dụng chất độn hoặc vật liệu gia cố bổ sung. Những chất này sẽ đảm bảo rằng các bộ phận của bạn có thành phần chắc hơn để chịu được nhiều lần sử dụng và hao mòn hơn. Các chất phụ gia như thế này sẽ cần được đưa vào trong giai đoạn pha trộn của quá trình sản xuất.

Bạn luôn có thể điều chỉnh các chất phụ gia của mình để đáp ứng các yêu cầu của bạn. Nhưng bất kể bạn sử dụng chất phụ gia nào, điều quan trọng là phải nghĩ đến bất kỳ thay đổi nào mà nó có thể tạo ra cho thành phần của bạn. Ví dụ, một số chất phụ gia có thể làm thay đổi màu sắc của bộ phận của bạn.

Nếu đây không phải là lựa chọn dành cho bạn và thành phần của bạn phải giữ nguyên màu ban đầu, hãy xem xét các tác động của nhiều loại hóa chất khác nhau và xác định phương án hành động tốt nhất trong quá trình sản xuất.

PBT có phù hợp với bạn không?

Cho dù bạn là người tiêu dùng hay chủ doanh nghiệp, PBT đều sở hữu những phẩm chất thiết yếu có thể phục vụ tốt cho bạn trong sản xuất. Nếu bạn là người có sở thích tự làm các bộ phận của mình cho nhiều mục đích khác nhau, PBT có thể cung cấp cho bạn độ bền và độ tin cậy.

Điều quan trọng cần nhớ là PBT hoạt động tốt trong các điều kiện phù hợp. Vì vậy, cần phải cân nhắc đến bối cảnh mà các bộ phận của bạn sẽ được sử dụng và điều chỉnh bằng các chất phụ gia nếu cần.

Đánh giá

Chưa có đánh giá nào.