Mô tả

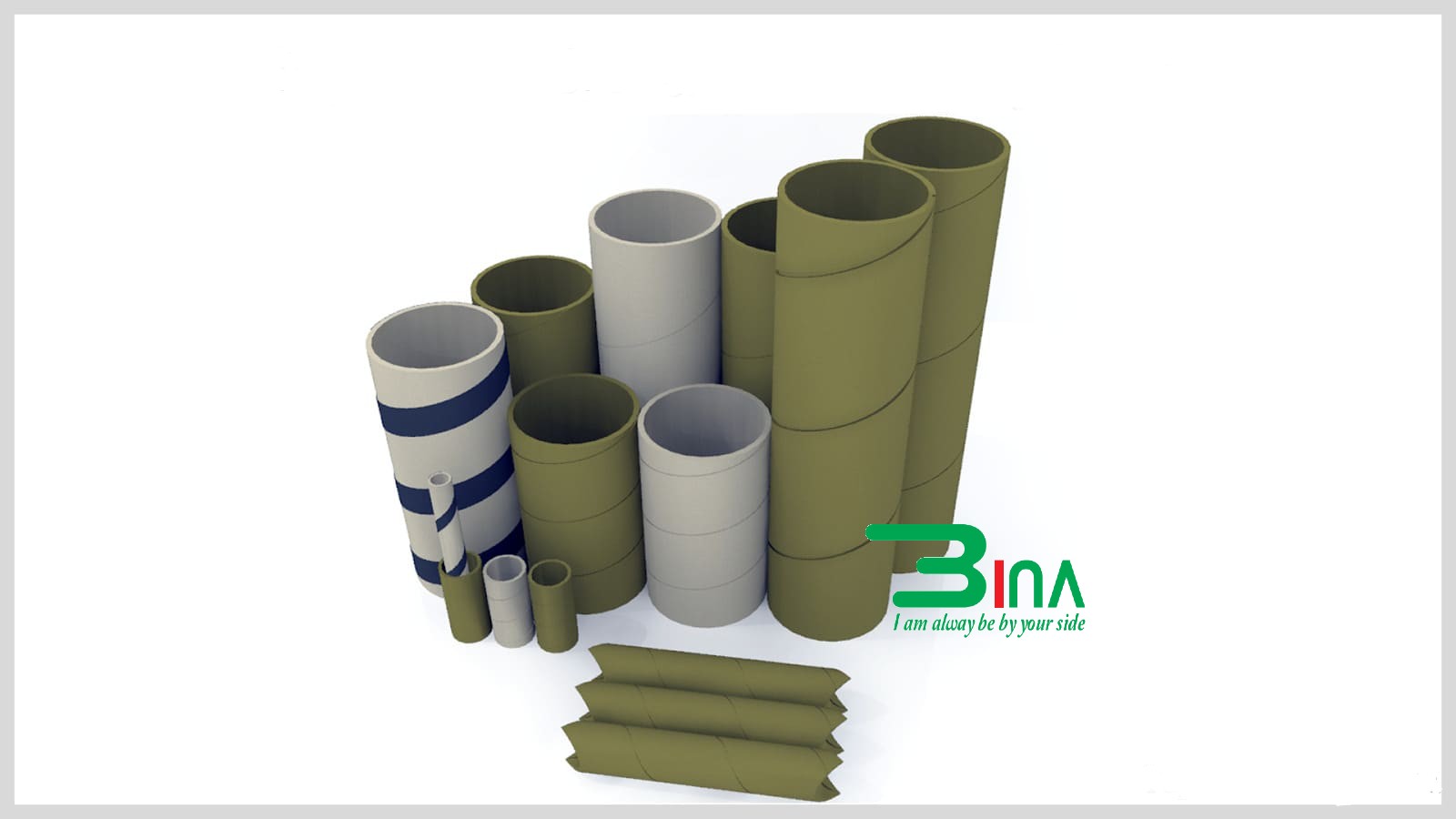

Ống lõi giấy carton là gì?

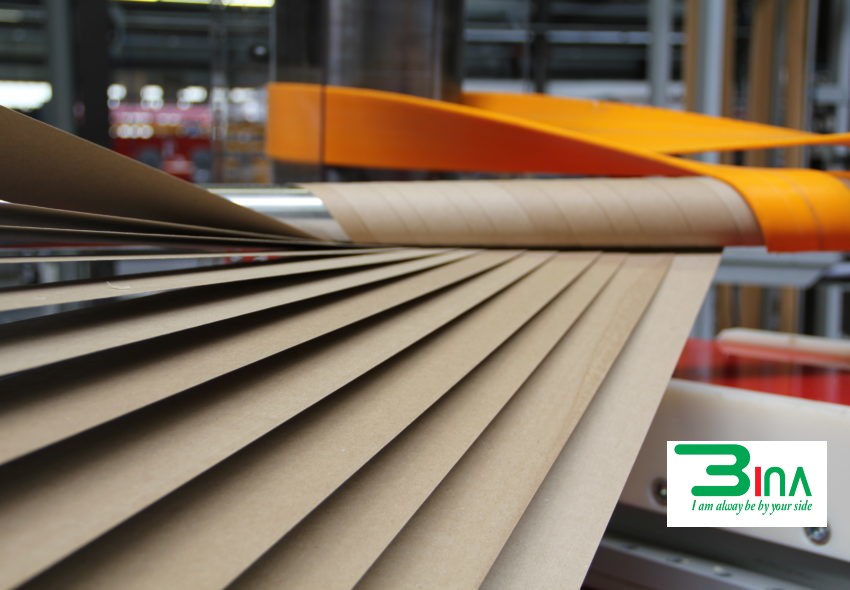

Ống lõi giấy carton được làm bằng cách quấn các lớp giấy hoặc tấm bìa cứng lại với nhau để tạo thành các hình dạng rỗng, chắc chắn, thường là hình trụ. Các lớp được cán mỏng hoặc liên kết bằng keo dán. Độ dày của thành ống có thể thay đổi tùy theo số lớp được sử dụng trong quá trình sản xuất.

Ống giấy, còn được gọi là lõi giấy, ống bìa cứng, hộp giấy, trống sợi, ống sợi, ống giấy, ống quấn, hộp composite, ống lõi và ống bìa cứng, thường được sử dụng trong nhiều ứng dụng khác nhau. Tuy nhiên, thuật ngữ “ống bìa cứng” là không chính xác, vì bìa cứng thường bao gồm ba lớp giấy kraft, với lớp ở giữa được làm gợn sóng.

|

Các loại và hình dạng ống giấy là gì

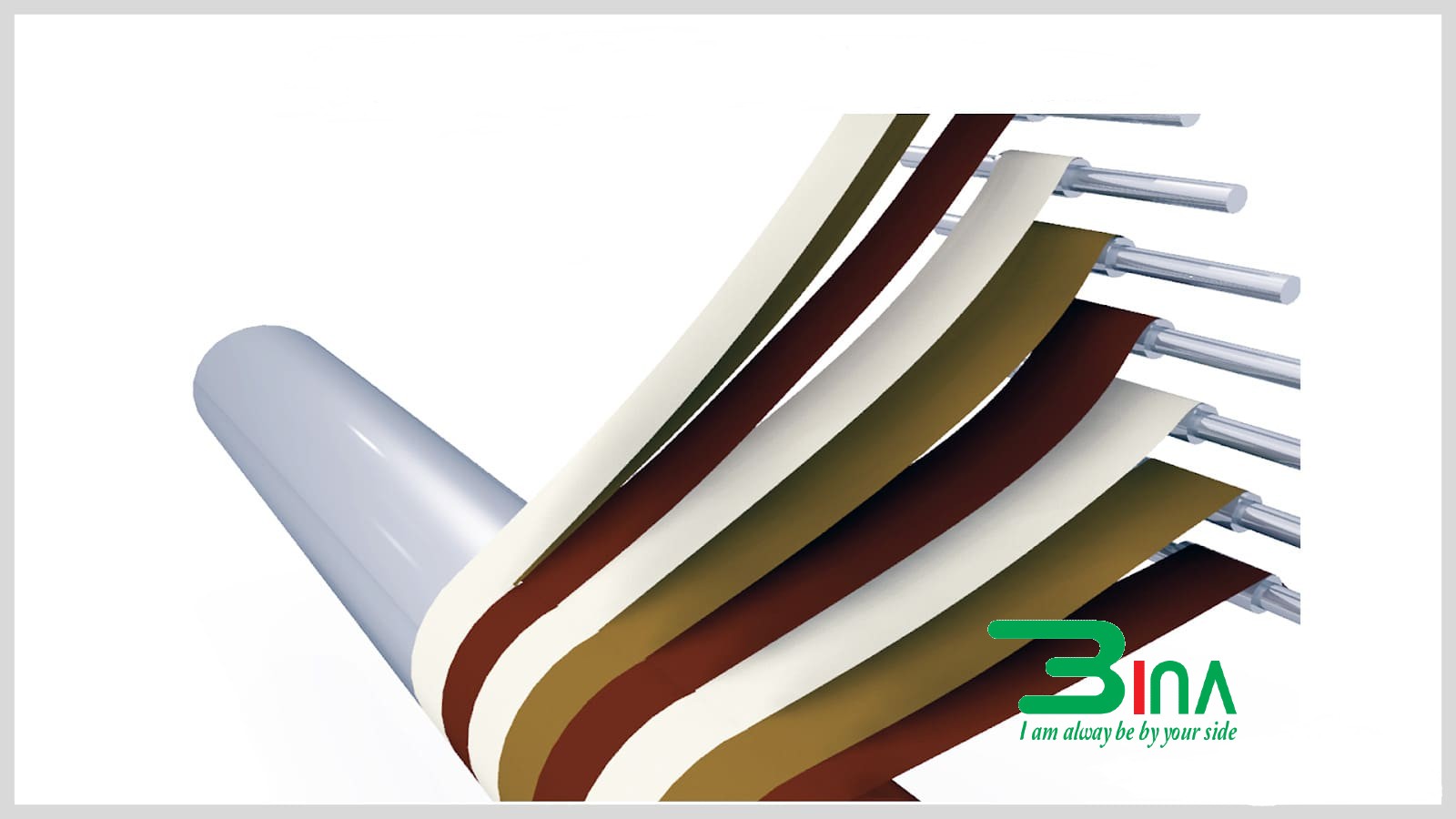

Trong khi ống giấy, lõi giấy và các sản phẩm liên quan được làm từ các lớp giấy hoặc bìa cứng quấn. Ống giấy hoặc lõi giấy có thể được chế tạo từ một, hai hoặc nhiều lớp giấy kraft nâu hoặc bìa cứng.

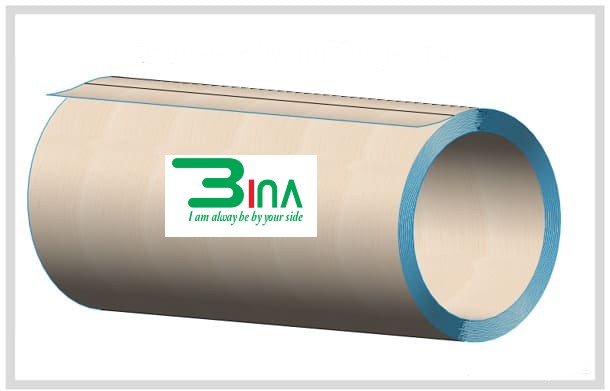

Lớp trong cùng, được gọi là lớp lót, và lớp ngoài cùng, được gọi là lớp bọc, có thể được làm từ nhiều loại vật liệu khác nhau như giấy bạc, màng hoặc giấy chuyên dụng. Các vật liệu này có thể có các tính năng như chống thấm nước, đồ họa hoặc nhãn mác và màu sắc cụ thể.

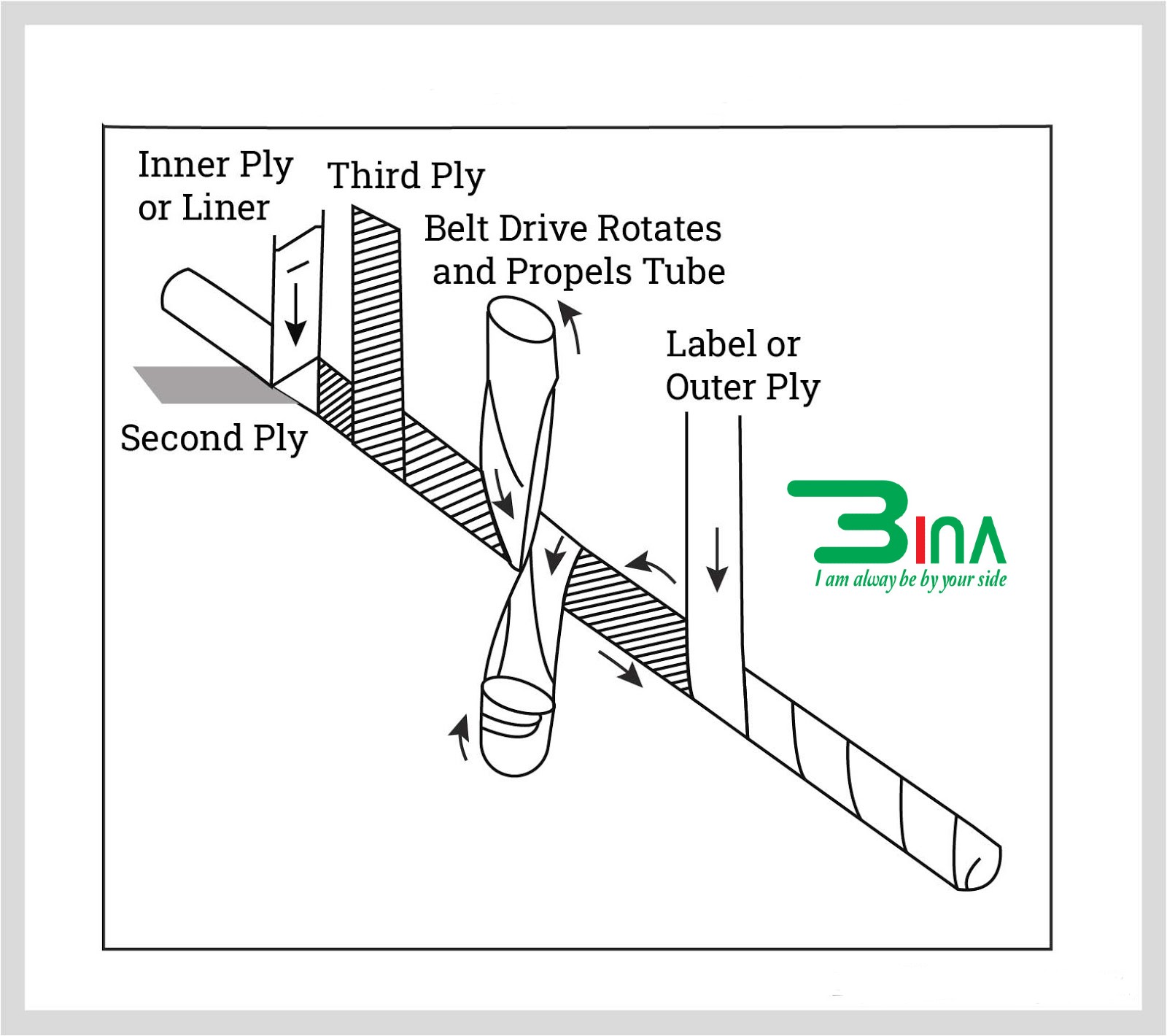

Hai loại ống giấy và lõi chính là ống giấy quấn xoắn ốc và ống giấy xoắn (hoặc quấn song song). Ống quấn xoắn được sử dụng trong các ứng dụng đòi hỏi độ bền uốn cao, khả năng chống nghiền và độ bền động.

Trong ống quấn xoắn ốc, các lớp giấy được quấn quanh ống theo một góc so với trục của ống. Trong ống xoắn, các cạnh của dải giấy được quấn song song hoặc theo góc 90 độ so với trục của ống.

|

Ống giấy có thành mỏng hơn và được sử dụng rộng rãi làm vật chứa hoặc bao bì cho sản phẩm.

Lõi giấy về cơ bản là ống giấy có thành dày. Thành dày hơn của lõi giấy khiến chúng phù hợp để cuộn các tấm hoặc tấm vật liệu mềm thành cuộn trong quá trình chuyển đổi.

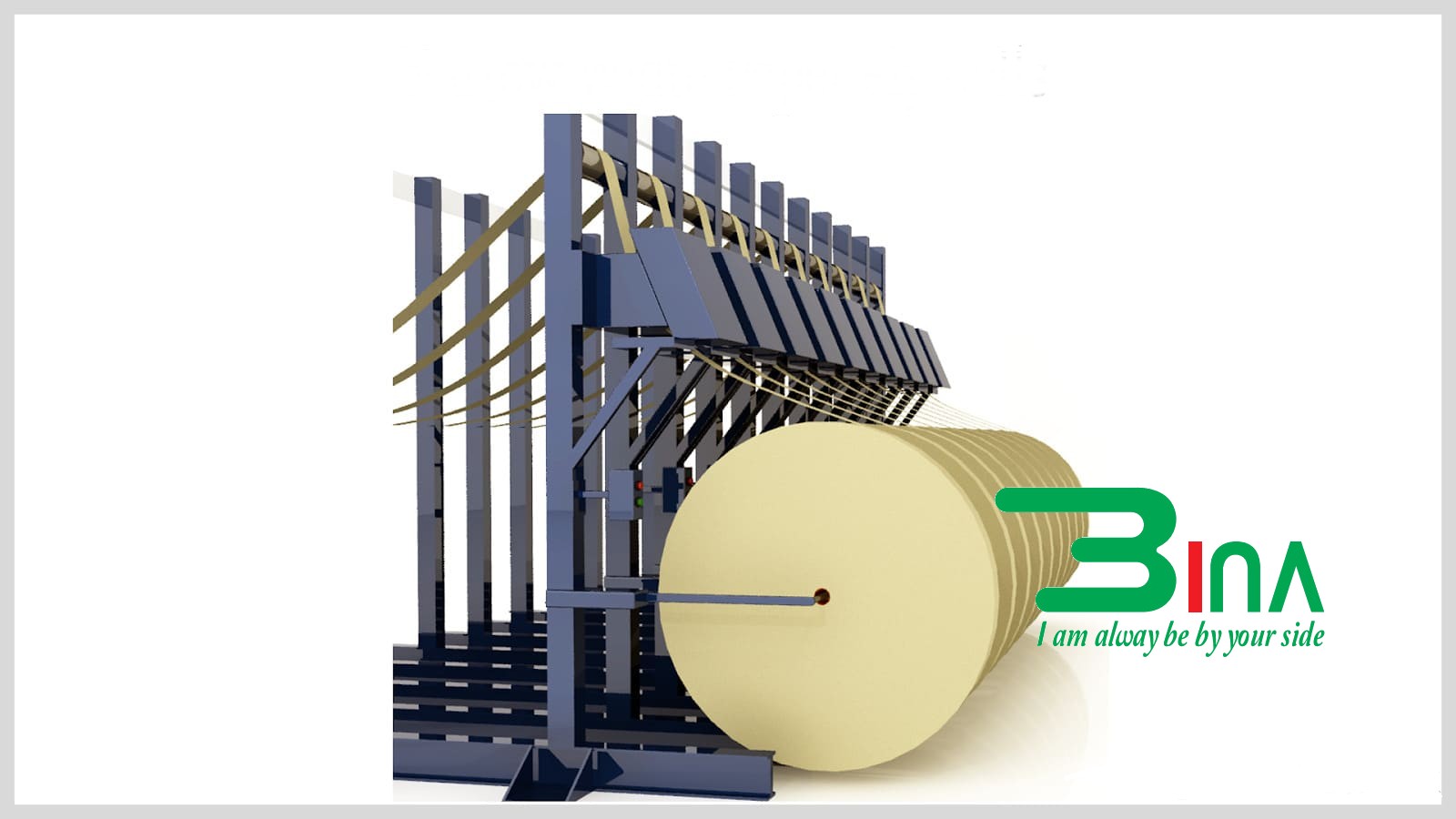

Máy giấy sản xuất các cuộn rất lớn, còn được gọi là cuộn máy, cuộn lớn, cuộn tambour hoặc cuộn mẹ. Các cuộn lớn này có thể được cắt quay hoặc được chuyển thành nhiều cuộn hẹp hơn bằng cách sử dụng máy cuộn có lõi bìa cứng. Các cuộn lớn tương tự cũng được sử dụng trong các nhà máy màng nhựa, giấy bạc, dệt may và mài mòn tráng phủ.

Bạn có thể ngạc nhiên khi biết rằng không phải tất cả các ống giấy đều được thiết kế để đóng gói. Lõi giấy cũng có thể đóng vai trò là thành phần máy. Ví dụ, lõi giấy được sử dụng để cuộn các cuộn lớn trong nhà máy giấy hoặc sản xuất màng nhựa yêu cầu lõi giấy có độ bền cực cao, thường là xoắn, để đáp ứng nhu cầu của các ứng dụng công nghiệp này.

Lõi giấy được sử dụng cho các cuộn băng dính, nhãn, giấy bạc, giấy, khăn giấy hoặc màng nhựa bán lẻ hoặc có đường kính nhỏ được thiết kế để đóng gói và phân phối. Những lõi này thường mỏng hơn và thường được quấn theo hình xoắn ốc.

|

Vật liệu ống giấy được cắt bằng phương pháp quay hoặc cưa để sản xuất nhiều sản phẩm khác nhau, bao gồm lon giấy, lon composite, ống vận chuyển, ống đẩy, ống pháo hoa, cột trưng bày, lõi chuyển đổi, khuôn đóng cọc bê tông và các mặt hàng ống giấy khác.

Các loại trống sợi lớn hoặc composite, cũng như ống hút giấy, được sản xuất bằng quy trình quấn tương tự. Máy quấn xoắn thường được sử dụng để sản xuất trống composite, cung cấp một giải pháp thay thế thân thiện với môi trường hơn cho trống thép. Mặt khác, ống hút giấy được quấn xoắn ốc ở tốc độ rất cao.

Hình dạng ống giấy

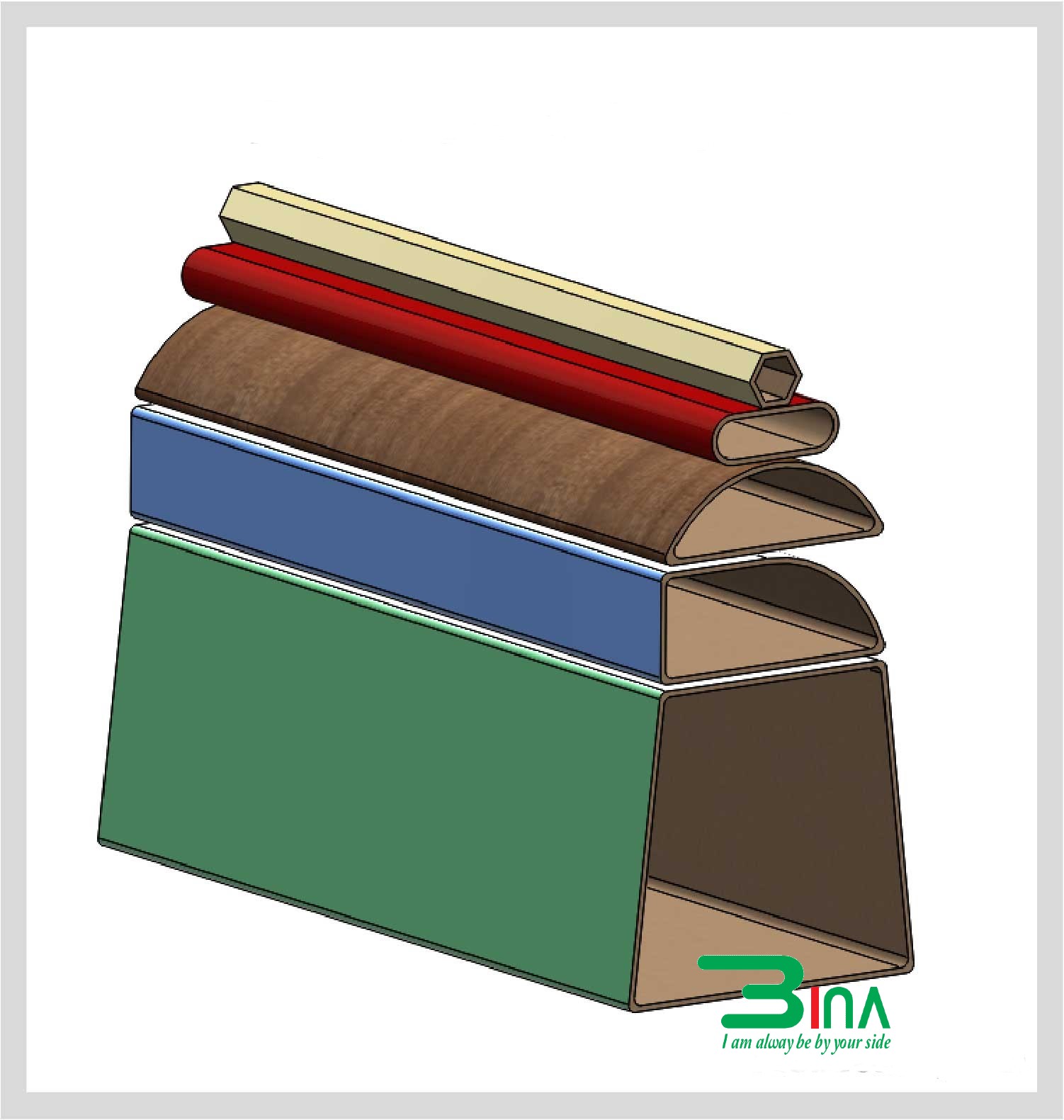

Hầu hết các ống giấy có mặt cắt ngang hình trụ hoặc tròn, nhưng chúng cũng có thể được tạo thành các hình dạng tùy chỉnh như hình vuông, hình bầu dục, hình lục giác hoặc hình tam giác bằng cách sử dụng các trục cuộn chuyên dụng. Các hình dạng tùy chỉnh giúp ống vừa khít với một bộ phận hoặc sản phẩm cụ thể, giảm không gian lãng phí và loại bỏ nhu cầu về các miếng đệm hoặc vật liệu đóng gói bổ sung.

Các ống giấy hình nón hoặc hình nón giấy được tạo ra bằng cách sử dụng một trục hình nón. Hình nón giấy thường được sử dụng làm vật mang sợi trong ngành dệt may.

Đối với các ứng dụng cụ thể, bạn có thể cần cắt hoặc rạch ống giấy theo chiều dọc để tạo thành nửa vỏ, có thể được sử dụng để bọc các cuộn lớn để bảo vệ. Các nửa vỏ này có thể được kết nối lại bằng băng dính hoặc thanh chữ H. Việc bọc một cuộn giấy hoặc cuộn thép cuộn bằng nửa vỏ thường dễ hơn là trượt cuộn vào một ống giấy bảo vệ lớn.

|

Ống giấy được sản xuất như thế nào?

Sản xuất ống giấy và lõi giấy

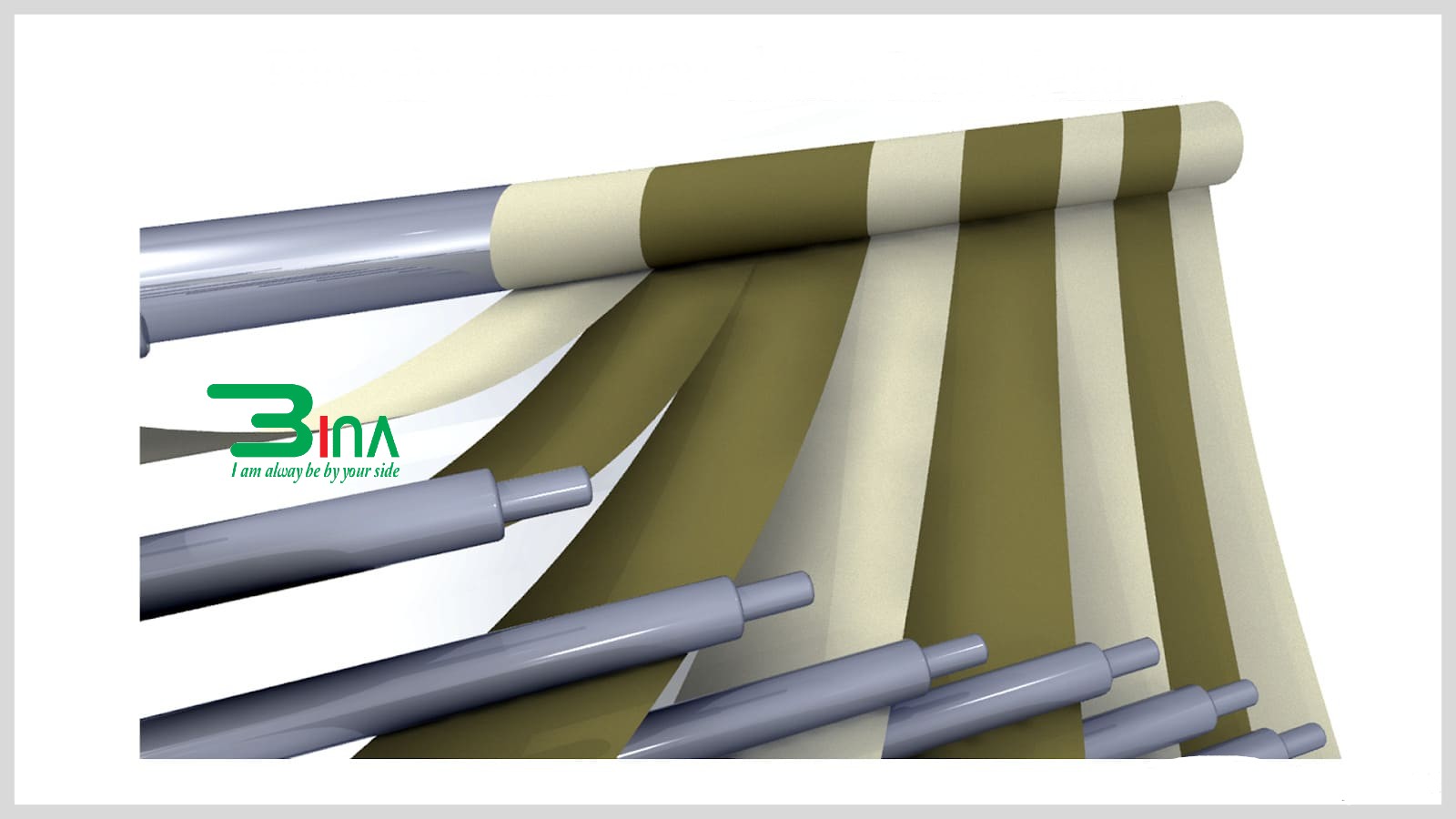

Sản xuất ống giấy và lõi giấy là một quá trình chuyển đổi bao gồm cắt lưới, quấn lưới và cán mỏng hoặc liên kết keo. Nhiều lớp hoặc lớp giấy hoặc bìa cứng được quấn quanh một trục thép theo nhiều vòng, tạo ra các ống hoặc lõi sợi cứng, có độ bền cao thông qua quá trình cán mỏng.

Dựa trên kinh nghiệm của tôi, các lớp thường có chiều rộng từ 2 đến 10 inch (50 đến 250 mm), mặc dù một số có thể rộng tới 20 inch (500 mm). Độ dày của mỗi lớp thường nằm trong khoảng từ 0,008 đến 0,050 inch (0,2 đến 1,3 mm). Tổng số lớp có thể thay đổi từ 1 đến hơn 50, nhưng lõi có từ 3 đến 30 lớp thường gặp hơn.

Độ bền của lõi giấy phụ thuộc vào một số yếu tố: độ bền liên kết của các lớp bìa cứng, độ dày của các lớp, diện tích liên kết hoặc chồng chéo và độ bền liên kết keo. Điều đặc biệt thú vị là bìa giấy có thể được sản xuất thông qua một quy trình làm giấy dày hơn hoặc bằng cách liên kết nhiều lớp với nhau. Do đó, một số ống giấy được tạo thành từ các lớp hoặc lớp nhiều lớp.

| Các bước trong quy trình sản xuất ống giấy |

| Máy móc được sử dụng | Các bước trong quy trình sản xuất sản phẩm ống giấy, lõi giấy và ống giấy |

| Máy cắt OffRotary | Cuộn giấy Jumbo được tháo ra và cắt thành những dải giấy hẹp hoặc nhiều lớp |

| Máy cuộn / Máy tháo cuộn | Cuộn các dải giấy hẹp hoặc các lớp giấy |

| Xe nâng Turk, xe đẩy hoặc xe xử lý vật liệu | Các chồng giấy hoặc cuộn bìa cứng được chuyển đến máy cuộn |

| Winder – Unwinder hoặc Unwinding Stands | Nhiều cuộn giấy mỏng hẹp được nạp vào trục/trục cuốn |

| Máy quấn – Máy dán keo hoặc máy bôi keo | Keo dán trên dải giấy hẹp |

| Máy quấn – Máy quấn & định hình | Dải giấy dán được quấn vào trục liên tục từ ống xoắn ốc |

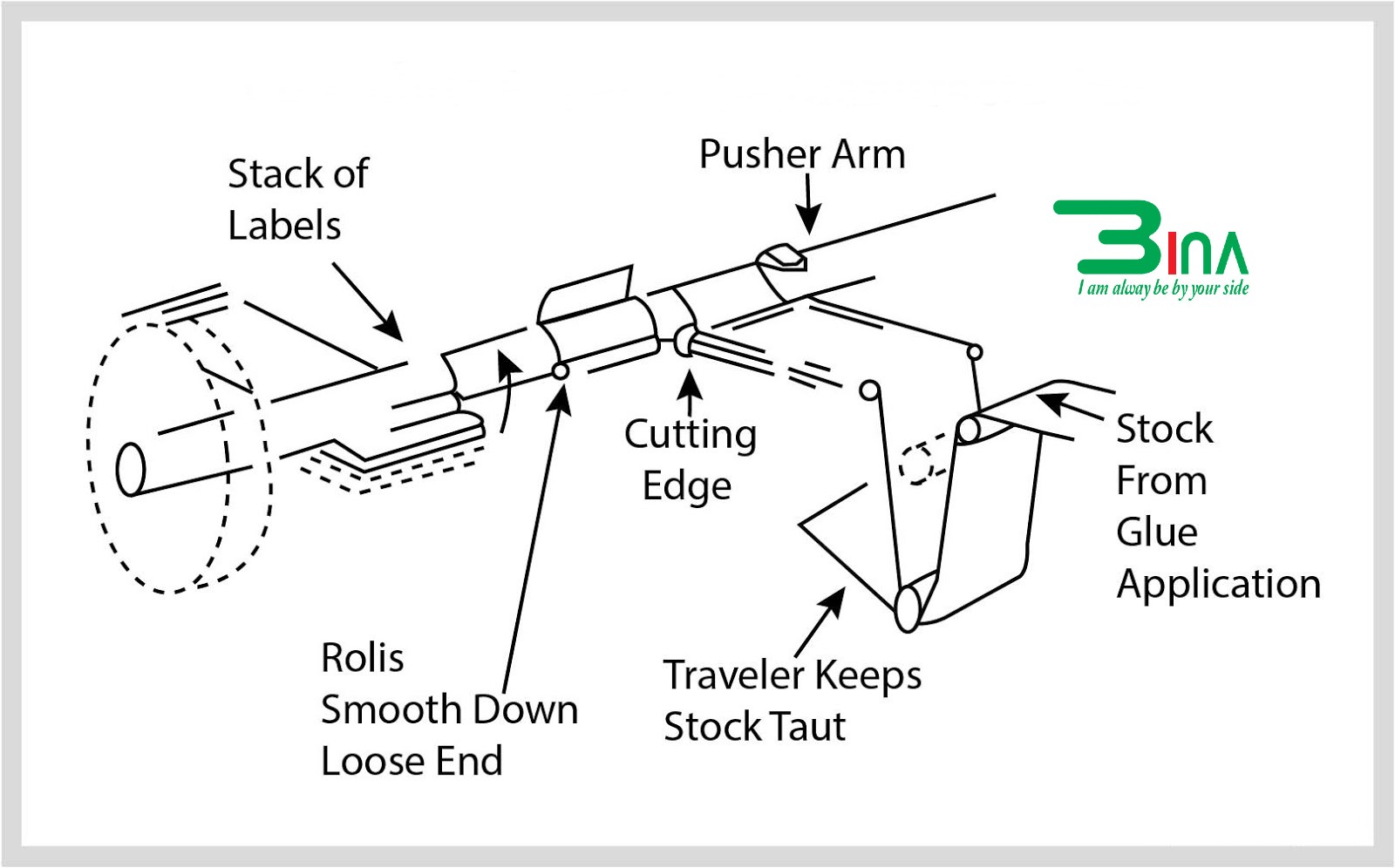

| Đơn vị in và dán nhãn nội tuyến | Dán nhãn bằng đồ họa in trên ống giấy trong quy trình nội tuyến |

| Máy cắt nội tuyến | Ống giấy xoắn cắt thành các đoạn ngắn hơn |

| Lò sấy ống | Chiều dài ống giấy xoắn được xử lý hoặc sấy khô trong lò |

| Máy in ngoại tuyến hoặc máy dán nhãn | Dán nhãn bằng đồ họa in trên ống giấy trong quy trình ngoại tuyến |

| Recutter hoặc máy cắt ngoại tuyến | Ống dài hơn được cắt thành chiều dài nhỏ hơn cần thiết cho mục đích sử dụng cuối cùng |

| Băng tải, xe đẩy hoặc máy xử lý vật liệu | Ống giấy cắt theo chiều dài được chuyển đến khâu hoàn thiện thứ cấp, cắt và đóng |

| Máy hoàn thiện ống | Loại bỏ gờ, loại bỏ bụi và đánh bóng hoặc cắt khi cần hoàn thiện bề mặt mịn hơn |

| Thiết bị đục lỗ hoặc cắt khuôn | Rãnh cuối, rãnh, cắt cửa sổ, đục lỗ, dập nổi |

| Thiết bị định hình và đóng nắp đầu ống | Tạo hình đầu, Chèn phích cắm, Đóng nắp hoặc Làm bích & Đóng nắp |

| Băng tải, Xe đẩy hoặc Máy xử lý vật liệu | Ống thành phẩm được chuyển đến máy đóng gói và xếp pallet |

| Máy xếp pallet và đóng gói | Ống giấy xếp chồng và đóng gói trên pallet, trong hộp hoặc trên xe đẩy thép |

| Bến tàu và xe tải | Sản phẩm ống giấy đóng gói được chất lên xe tải và vận chuyển đến khách hàng |

Quy trình sản xuất ống giấy có thể bao gồm quấn, gấp và uốn, tùy thuộc vào hình dạng mong muốn của sản phẩm cuối cùng, chẳng hạn như tròn, vuông hoặc hình nón.

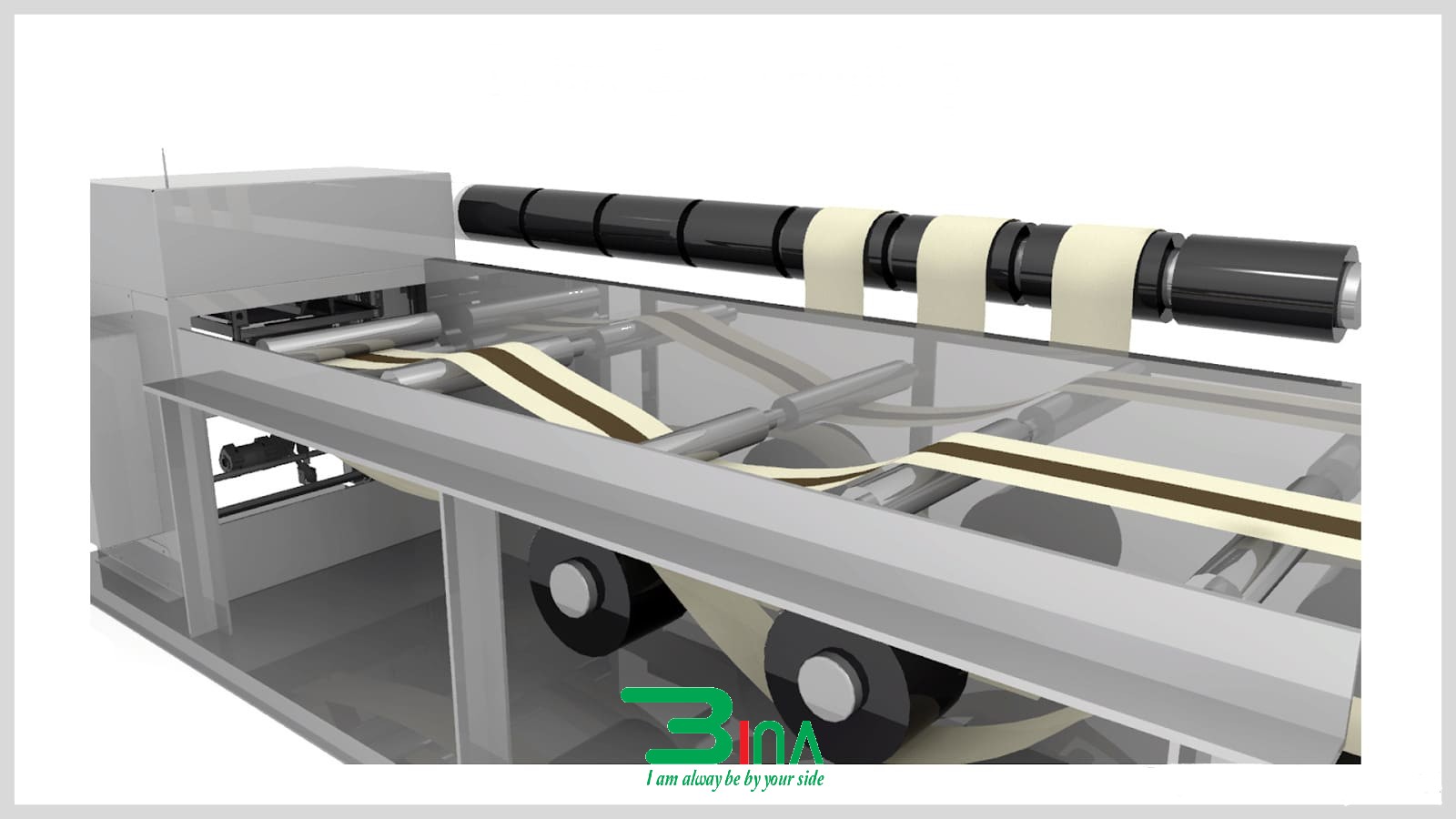

Sản xuất ống giấy xoắn hoặc lõi

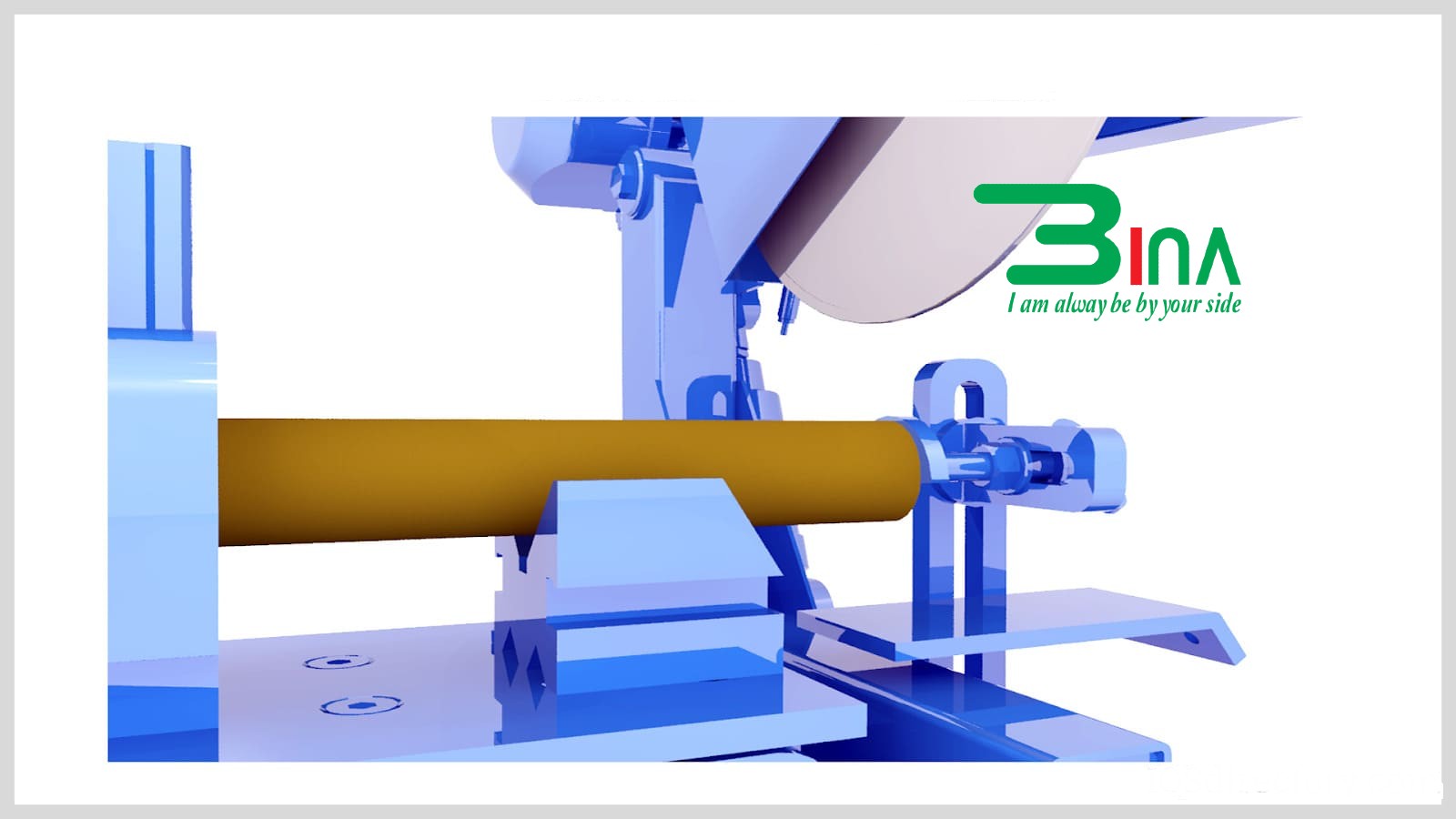

Trong quy trình sản xuất ống giấy xoắn hoặc lõi, các cuộn giấy, bìa cứng và vật liệu lót lớn đầu tiên được chuyển thành các dải băng hẹp hơn thông qua hoạt động cắt quay. Sau đó, các dải băng giấy này được quấn lại thành các cuộn hẹp bằng giá đỡ quấn lại.

Các cuộn băng giấy hẹp được xếp chồng lên nhau thành các đống “chip poker” lớn. Các chồng “chip poker” này sau đó được vận chuyển và nạp vào máy sản xuất ống.

|

Các dải băng giấy hẹp từ nhiều cuộn được dẫn hướng và gắn, dán hoặc dán vào một trục thép. Chúng được sắp xếp theo kiểu chồng lên nhau hoặc có khoảng cách giữa các cạnh trước. Sự sắp xếp hoặc khoảng cách này cho phép các dải băng được đưa vào trơn tru mà không cản trở nhau.

Bằng cách gắn cạnh trước của dải băng theo hướng xiên hoặc theo góc nhỏ hơn 90 độ so với trục của trục, một hình xoắn ốc sẽ xảy ra trong quá trình quấn.

|

Đường kính ngoài của trục thép quyết định đường kính bên trong của ống giấy thành phẩm. Độ dày thành ống phụ thuộc vào độ dày của ruy băng giấy hoặc bìa cứng, độ dày của chất kết dính và số lượng ruy băng được sử dụng trong quá trình này.

Chất kết dính hoặc keo được bôi lên từng ruy băng giấy hoặc lớp trước khi quấn vào trục thép. Theo kinh nghiệm của tôi về việc phủ các lớp giấy, vải, sợi lưu hóa và màng nhựa, có thể sử dụng nhiều loại máy phủ màng để phủ keo lên các lớp, bao gồm:

- Máy phủ trục lăn

- Máy phủ trục lăn ngược

- Máy phủ khuôn khe

- Máy phủ đùn

- Máy phủ rèm

- Máy phủ chổi

- Máy phủ phun

- Máy phủ lưỡi

- Máy phủ thanh định lượng

- Máy phủ nhúng

|

Điều hấp dẫn là cách băng ống giấy xoắn thành hình xoắn ốc, liên tục tạo hình và liên kết các lớp ống giấy với nhau. Băng mềm dẻo quấn quanh các lớp giấy, tạo áp lực để đảm bảo liên kết keo thích hợp giữa các ruy băng. Ngoài ra, đai cao su gia cố vải đẩy ống dọc theo trục.

Tôi có thể hình dung rằng ứng suất và nhu cầu về hiệu suất trên đai tạo ống giấy là rất lớn. Các đai này vô tận hoặc liền mạch để tránh đánh dấu, tự hào có độ bền kéo cao và ma sát cao để bám và di chuyển ống hiệu quả. Ngoài ra, chúng dễ vệ sinh. Một số nhà cung cấp đai tạo ống bao gồm Nitta, Passaic và Rainbow.

Tiếp theo, khi các lớp giấy bổ sung được thêm vào một đầu của trục tạo ống giấy, ống giấy đã tạo hình hoặc cán mỏng sẽ trượt ra khỏi đầu kia và được cắt theo chiều dài bằng cách cắt bằng lưỡi quay hoặc các hoạt động cưa ngoại tuyến. Tùy thuộc vào mục đích sử dụng cuối cùng, có thể thực hiện thêm quá trình loại bỏ ba via ở mép đầu ống.

Một khía cạnh hấp dẫn khác của quy trình sản xuất ống giấy là khả năng sản xuất một loạt lớn các sản phẩm ống giấy hoặc kết hợp vật liệu tùy chỉnh cao bằng cách sử dụng các lớp vật liệu khác nhau.

Lớp lót hoặc lớp lót được áp dụng cho đường kính bên trong (ruy băng đầu tiên) hoặc đường kính bên ngoài (ruy băng cuối cùng) của ống để tăng khả năng chống nước, độ ẩm hoặc dầu mỡ. Các lớp lót này có thể được làm bằng tấm kim loại, giấy bạc, giấy tráng (sáp, silicon hoặc nhựa), màng nhựa và các vật liệu bảo vệ khác.

Nếu ứng dụng hiện tại của bạn không đáp ứng được các ống giấy hiện có, nhà sản xuất ống giấy tùy chỉnh có thể thiết kế một sự kết hợp mới giữa lớp lót, lớp phủ và lớp bọc để đáp ứng các nhu cầu cụ thể của ứng dụng chuyên biệt của bạn, miễn là khối lượng đơn hàng đủ lớn.

Một tính năng đáng chú ý của sản xuất ống giấy là khả năng nâng cao thương hiệu thông qua nhãn mác hoặc in ấn, cả bên trong và bên ngoài. Nếu cần đồ họa in hoặc trang trí trên ống giấy, có thể sử dụng ruy băng giấy hoặc vật liệu có thể in cho ruy băng đầu tiên và cuối cùng. Ví dụ, có thể sử dụng giấy trắng hoặc bìa cứng cho lớp ngoài, trong khi có thể sử dụng giấy kraft nâu bền hơn cho các lớp bên trong.

|

Ống giấy Convolute

Trong quy trình sản xuất ống giấy xoắn hoặc lõi song song, các cuộn giấy, bìa cứng và vật liệu lót lớn được cắt thành các dải rộng hơn, không giống như các dải rất hẹp được sử dụng trong sản xuất ống xoắn. Trong quy trình này, cạnh trước của dải được căn chỉnh song song với trục của ống giấy, tạo ra một đường nối hoặc vạt đơn chạy dọc theo chiều dài của ống giấy.

Có thể sử dụng một cuộn kim loại bên ngoài để tạo áp lực thay vì dây đai, giúp loại bỏ các lỗ rỗng hoặc túi khí và đảm bảo tiếp xúc keo dính tốt hơn, tạo ra liên kết chặt chẽ hơn giữa các lớp giấy. Vì lớp giấy rộng hơn nên có thể tạo áp lực và độ căng cao hơn trong quá trình cuộn xoắn. Những áp lực và độ căng cao hơn này góp phần tạo ra các ống có độ bền lớn hơn so với ống xoắn ốc.

|

Lõi giấy xoắn có độ bền chùm lớn hơn lõi xoắn ốc, khiến chúng trở nên rất mong muốn để sản xuất và chuyển đổi lớp giấy. Quy trình ống giấy xoắn được sử dụng để tạo lõi chịu lực cao, chịu tải nặng để cuộn và tháo cuộn lớn các cuộn giấy mềm dẻo, chẳng hạn như:

- Giấy và bìa cứng

- Chất mài mòn tráng

- Màng nhựa và tấm cao su

- Vải dệt và không dệt

- Tấm kim loại và giấy bạc

- Thảm và sàn

|

Khi xem xét lõi giấy, bạn nên coi nó như một thành phần quay tương tự như ổ trục, bánh răng, mâm cặp và trục. Trong các hoạt động chuyển đổi chịu tải nặng, lõi giấy hoạt động như các bộ phận máy móc chứ không chỉ là đóng gói sản phẩm, vì chúng đóng vai trò quan trọng trong hoạt động và tính toàn vẹn của máy sản xuất và xử lý cuộn giấy. Lõi giấy xoắn ốc phù hợp cho các ứng dụng nhẹ hơn, chẳng hạn như đóng gói và phân phối các cuộn nhãn, băng keo, giấy bạc, giấy lụa, giấy hoặc màng nhựa nhỏ hơn.

Sản xuất ống xoắn và ống xoắn kết hợp

Quy trình sản xuất ống xoắn và ống xoắn được kết hợp để sản xuất một số ống. Ví dụ, ống xoắn được làm bằng giấy kraft có thể có lớp giấy trắng bên ngoài hoặc lớp nhựa có đồ họa và nhãn được quấn quanh bên ngoài ống bằng quy trình quấn xoắn.

|

Quy trình sản xuất ống giấy liên quan

Bạn sử dụng lõi giấy và các sản phẩm liên quan hàng ngày trong cuộc sống hàng ngày mà không hề nhận ra. Khăn giấy, khăn giấy ăn, giấy bạc, màng bọc thực phẩm đều được quấn trên ống giấy để dễ dàng phân phối. Nếu bạn mở tủ bếp, bạn sẽ thấy nhiều loại hộp đựng giấy, hộp đựng composite và các loại hộp đựng ống giấy khác. Trống sợi, máy làm ống hút và cốc giấy được sản xuất bằng công nghệ tương tự.

Máy làm trống sợi, máy làm ống hút, máy làm cốc giấy và máy làm lon composite sử dụng công nghệ xử lý tương tự như máy quấn ống giấy.

Ngoài ra, các nhà sản xuất ống giấy và OEM máy móc đã phát triển các quy trình được cấp bằng sáng chế và độc quyền để sản xuất ống giấy. Các phương pháp chuyên biệt này được thiết kế để sản xuất ống và lõi có độ bền cao hơn, trọng lượng giảm hoặc các đặc tính và chức năng độc đáo khác. Ví dụ, PAKEA đã thiết kế và cấp bằng sáng chế cho hệ thống tạo hình ống tuyến tính SIRPAK® để cải thiện sản xuất lon composite không tròn.

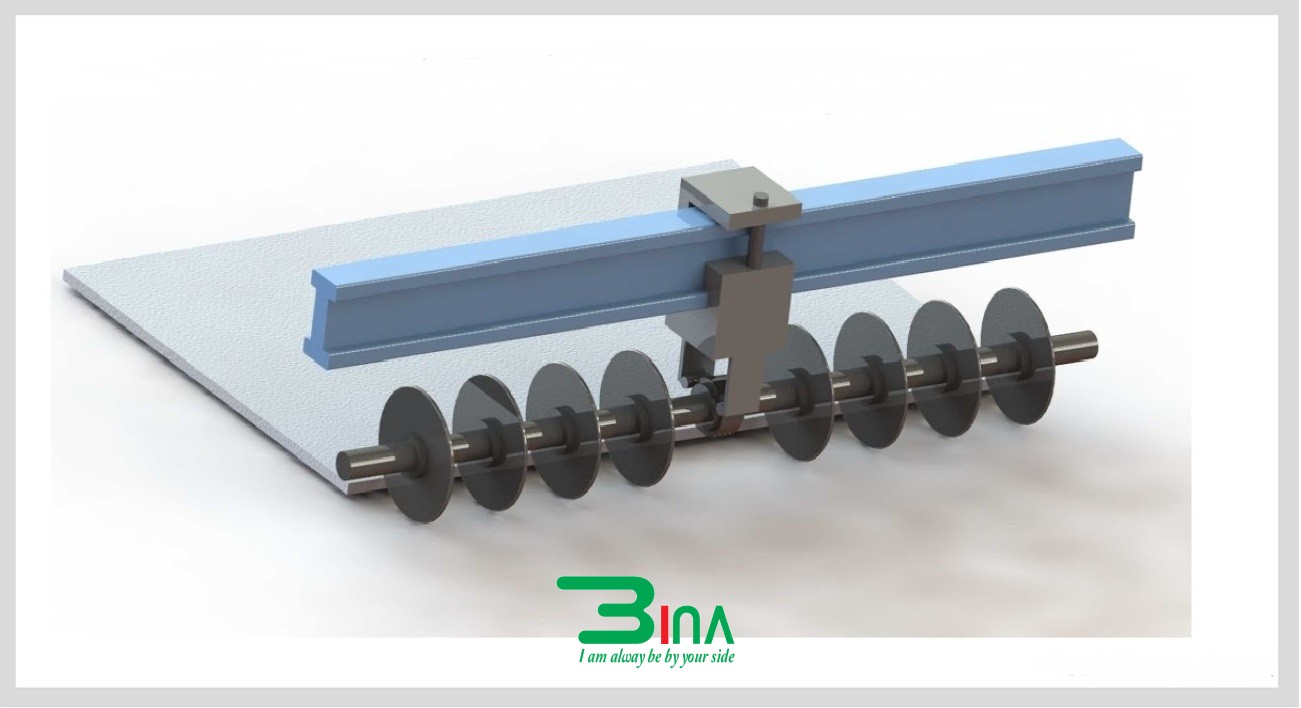

Cắt và cắt lại ống giấy

Sau khi ống giấy được tạo thành trên máy cuộn xoắn ốc hoặc cuộn tròn, ống giấy được cắt thành các đoạn ngắn hơn bằng cả máy cắt trực tuyến và ngoại tuyến. Khi ống xoắn nhiều lớp trượt ra khỏi trục, ống được sản xuất liên tục. Vật liệu ống xoắn có thể được cắt theo chiều dài hoàn thiện bằng máy cắt trực tuyến hoặc thành các đoạn dài hơn, sau đó được xử lý bằng máy cắt lại hoặc máy cắt lại ngoại tuyến. Trong quá trình này, các đoạn trung gian có thể được bọc bên ngoài bằng màng bảo vệ hoặc giấy bạc, đồ họa in, nhãn hoặc xử lý bề mặt trước khi được cắt thành chiều dài cuối cùng. Cắt trực tuyến được thực hiện bằng máy cắt lưỡi quay.

|

Nếu bạn cần các đường cắt rất sạch và độ dài đồng đều, cắt lưỡi quay là lựa chọn lý tưởng. Lưỡi cắt hoặc cưa cắt quay được sử dụng để cắt ngoại tuyến. Cắt lưỡi quay thường tạo ra các cạnh sạch hơn, sắc hơn và dung sai chặt chẽ hơn. Cắt bằng cưa có thể hiệu quả đối với các ống có thành rất dày, nhưng nó tạo ra các gờ và bụi cần được loại bỏ khỏi ống giấy hoặc lõi. Cắt bằng lưỡi dao cho phép cắt theo chiều dài chặt chẽ hơn, trong khi chiều dài cắt bằng cưa có thể thay đổi tới 1/16” (0,062”).

Hoạt động hoàn thiện ống

Như đã thảo luận, các hoán vị khác nhau của vật liệu lớp có thể dẫn đến nhiều khả năng sản phẩm ống giấy. Thậm chí có thể đạt được nhiều biến thể hơn thông qua xử lý bề mặt, lớp phủ, nhúng, tẩm và quấn xoắn ngoại tuyến.

Xử lý bề mặt ống giấy có thể bao gồm nhúng hoặc tẩm ống bằng sáp, silicon hoặc các lớp phủ chống thấm khác để tăng khả năng chống nước của chúng.

|

Đối với các ứng dụng quấn cụ thể, đường kính bên trong hoặc bên ngoài của ống được đánh bóng và các gờ ở các cạnh ngoài được loại bỏ để đảm bảo lõi giấy có thể được nạp trơn tru vào máy móc và di chuyển tự do.

In đồ họa và dán nhãn quấn vào ống để đóng gói có thể được thực hiện trực tuyến hoặc ngoại tuyến. Cả quy trình quấn xoắn và quấn xoắn đều được sử dụng để dán nhãn.

Tạo hình, cắt và đóng nắp đầu ống

Nếu ống giấy được dùng làm miếng đệm, khuôn bê tông, mặt nạ hoặc cột, thì ống cắt theo chiều dài có thể hoàn thiện và sẵn sàng để đóng gói và vận chuyển. Tuy nhiên, nếu ống dùng cho mục đích đóng gói, thì cần có các quy trình bổ sung như tạo rãnh, cắt khuôn, tạo mép, niêm phong, đóng nắp, cán đầu hoặc tạo hình đầu để tạo ống vận chuyển, hộp giấy hoặc hộp composite.

Bạn cũng sẽ nhận ra lợi ích của các hoạt động thứ cấp có giá trị gia tăng như dập nổi, khía, khía, rạch và cắt khuôn cửa sổ. Ví dụ, lõi giấy có thể có các khía được cắt vào đầu để hỗ trợ việc cuộn và tháo màng phim, băng keo, vải hoặc các vật liệu cuộn khác đã chuyển đổi.

Có thể cắt các lỗ ở bên hông hộp đựng ống giấy và dán một lớp màng nhựa vào đường kính bên trong để tạo cửa sổ xem hàng hóa đóng gói bên trong. Dập nổi tạo thêm hoa văn nổi trên bề mặt ống. Dập nổi chức năng, với các gờ nổi trên bề mặt lõi giấy, có thể tăng cường độ bám của vật liệu dạng cuộn trong quá trình cuộn.

|

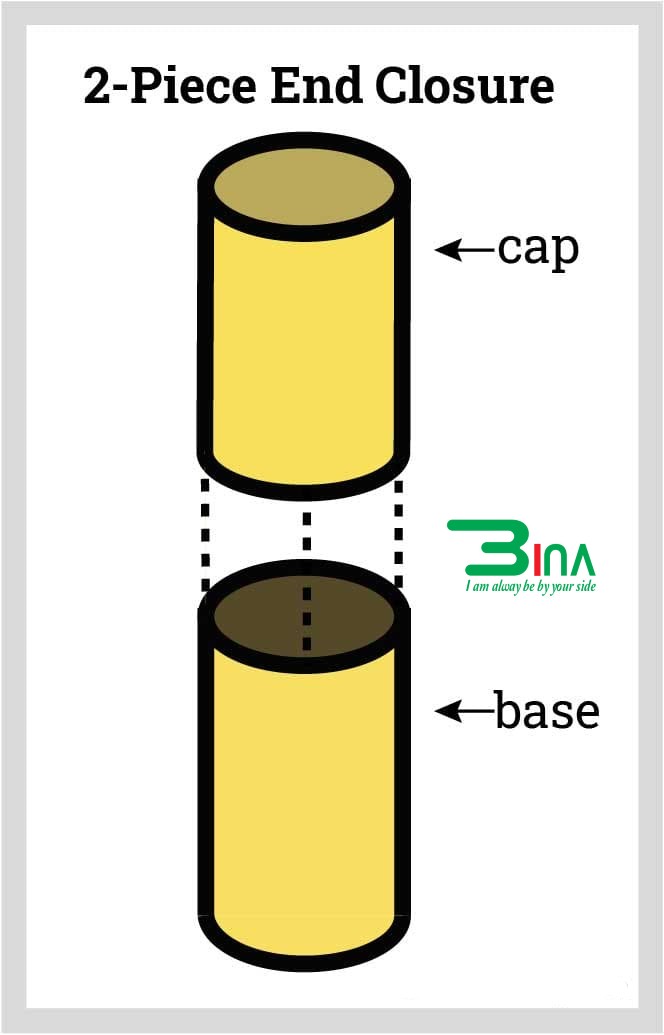

Có thể thêm một tính năng đóng vào ống giấy để tạo thành hộp giấy, ống thư hoặc vật liệu đóng gói dạng ống khác. Có thể thực hiện đóng ống giấy bằng cách cuộn hoặc tạo hình đầu ống để tạo thành các cạnh tròn và chèn một đĩa giấy, bằng cách sử dụng nút chặn hoặc nắp, hoặc bằng cách kết hợp tạo hình đầu với các kỹ thuật đóng nắp.

Nắp ở đầu ống giấy có thể là vĩnh viễn hoặc có thể tháo rời. Các đầu đóng vĩnh viễn bao gồm:

- Đầu cốc giấy

- Đầu cắm hoặc nắp nhựa cố định

- Đầu cắm, đầu cắm hoặc nắp kim loại được khâu lại

Các hộp đựng ống giấy cũng có thể có đầu kim loại được khâu lại hở, có thể chấp nhận nút ma sát kim loại có thể tháo rời.

Một loại nắp ống giấy mà tôi thấy đặc biệt hấp dẫn vì tính đơn giản và chức năng của nó là nắp snap-loc. Nắp đầu gấp, uốn hoặc snap-loc là một trong những loại dễ sản xuất và sử dụng nhất. Nắp đầu uốn, còn được gọi là nắp mở EZ, đầu “snap-seal” hoặc đầu “tự hàn”, liên quan đến việc uốn cong hai cạnh của ống giấy vào trong. Người dùng cuối có thể dễ dàng kẹp mở và đóng nắp bằng cách bấm.

Ống cũng có thể được uốn hình sao và sử dụng làm nút chặn bên trong các đầu lõi để cung cấp thêm khả năng hỗ trợ và ngăn ngừa sụp đổ hoặc đè bẹp. Ống giấy uốn hình sao có các nút chặn chạy song song với trục của ống. Một kỹ thuật uốn tương tự thường được sử dụng trên ống dẫn kim loại tròn để lắp ráp ống dẫn.

Các ống lưu trữ, vận chuyển và gửi thư thường sử dụng nút chặn bằng nhựa, gỗ hoặc kim loại để đóng các đầu. Trong khi các nút chặn ma sát thường cung cấp khả năng vừa khít an toàn, một số ứng dụng có thể yêu cầu thêm băng dính hoặc ghim bấm qua thành ống để ngăn nút chặn bị bung ra và đảm bảo ống vẫn được đóng an toàn trong quá trình vận chuyển hoặc xử lý.

Một lựa chọn khác là sử dụng hai nắp đậy vừa khít với các đầu bên ngoài của ống. Những nắp này có thể được làm từ nhựa, kim loại hoặc giấy. Có sẵn các loại nắp và phích cắm chuyên dụng cho các ứng dụng cụ thể: nắp có khe để đựng tiền xu hoặc vé, nắp rây có lỗ để phân phối bột và hàng khô, và phích cắm hoặc nắp có mặt ngoài hình vuông hoặc có tab để chống lăn.

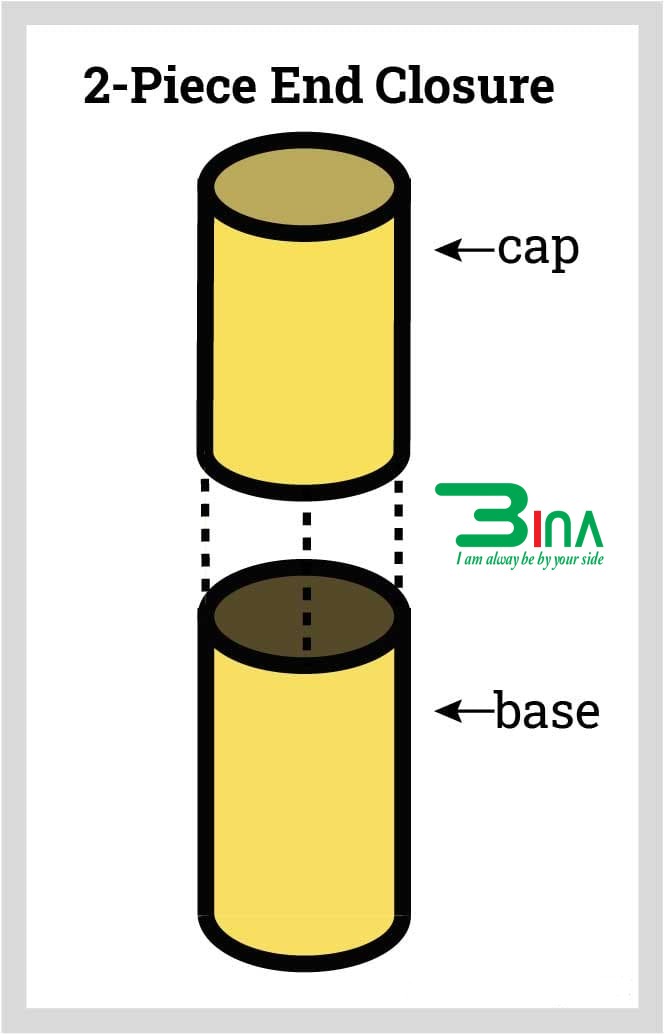

Có thể làm hộp đựng ống giấy bằng cách sử dụng ống giấy dạng ống lồng, trong đó ống bên trong có đường kính ngoài nhỏ hơn một chút so với đường kính trong của ống ngoài. Những hộp đựng này có thể được chế tạo theo kiểu ống lồng hai mảnh hoặc ba mảnh, thường có các đầu cuộn với nút chặn bằng giấy hoặc đĩa gỗ.

- Ống ống lồng hai mảnh có thể điều chỉnh độ dài, cho phép đóng gói hoặc lưu trữ các tài liệu hoặc hàng hóa có chiều dài khác nhau với một sản phẩm ống giấy.

- Hộp đựng ống giấy ba mảnh thường được sử dụng để đóng gói rượu vang, mỹ phẩm và các mặt hàng cao cấp khác.

|

|

|

Trong khi bạn có thể nghĩ rằng sản phẩm dạng ống giấy chỉ phù hợp với hàng khô, thì thật ngạc nhiên là tôi thấy không phải vậy. Trong các ứng dụng đóng gói sản phẩm ướt hoặc đông lạnh như nước cam đông lạnh, cần phải tạo mép, niêm phong và đóng nắp ống giấy để tạo ra bao bì kín, chống rò rỉ. Thông thường, “đầu thiếc” hoặc đầu nối kim loại được sử dụng khi tạo mép ở đầu ống và nắp kim loại có thêm chất bịt kín bên trong mối nối.

Đóng gói và xếp pallet ống giấy

Tôi nhận thấy rằng bước cuối cùng trong sản xuất—đóng gói—thường không được quan tâm đúng mức. Tuy nhiên, đóng gói là rất quan trọng vì việc bảo vệ không đầy đủ có thể dẫn đến hư hỏng, làm giảm đáng kể công sức nếu sản phẩm không được bảo vệ trong quá trình vận chuyển và lưu trữ tại địa điểm của khách hàng.

Bước cuối cùng trước khi vận chuyển ống giấy thành phẩm, lõi giấy và các sản phẩm ống giấy khác là xếp pallet và đóng gói để đảm bảo chúng không bị hư hỏng trong quá trình vận chuyển. Phương pháp đóng gói có thể thay đổi tùy theo yêu cầu của khách hàng, nhưng ống giấy và lõi giấy thường được đóng gói trong:

- Thùng carton sóng

- Đóng pallet

- Đóng bó

- Xe đẩy bằng thép có bánh xe có thể trả lại, giúp di chuyển dễ dàng tại nhà máy của khách hàng.

Ngoài ra, một số nhà sản xuất ống giấy cung cấp dịch vụ chiết rót và niêm phong hoặc có thể đóng gói sản phẩm của khách hàng trực tiếp vào hộp đựng ống giấy.

|

Vật liệu xây dựng ống giấy

Bạn sẽ thấy rằng phần lớn ống giấy và lõi giấy được làm từ giấy kraft và bìa cứng. Giấy và bìa cứng đều có nguồn gốc từ bột giấy, xenluloza hoặc sợi thực vật. Bìa cứng thường dày 12 điểm hoặc 0,012 inch trở lên, trong khi giấy mỏng hơn 12 điểm theo định nghĩa của TAPPI. Tiêu chuẩn ISO định nghĩa bìa cứng là loại giấy có định lượng trên 250 g/m².

Giấy kraft Giấy kraft là loại giấy được sử dụng phổ biến nhất để làm ống giấy do độ bền của nó. Được làm từ bột gỗ mềm có sợi dài, giấy kraft bền hơn giấy trắng hoặc các loại giấy khác. Bản thân thuật ngữ “kraft” bắt nguồn từ các từ tiếng Đức và tiếng Thụy Điển có nghĩa là độ bền.

|

Giấy lõi là loại bìa cứng chuyên dụng được thiết kế để sản xuất lõi giấy và thường được làm từ 100% vật liệu tái chế. Bìa cứng tái chế không tráng phủ (URB) cũng thường được sử dụng để làm ống giấy và lõi giấy.

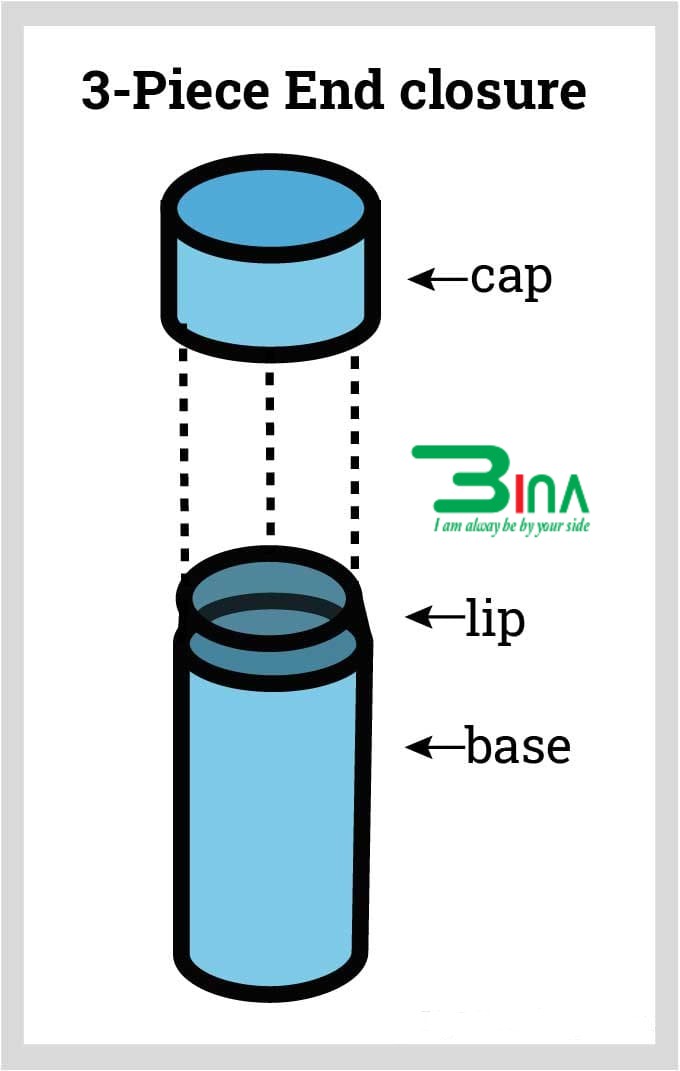

Ống giấy bao gồm một hoặc nhiều lớp, gồm ba loại:

- Lớp lót hoặc lớp ID – Lớp lót nằm trên đường kính bên trong và là lớp đầu tiên được quấn quanh trục trong quá trình quấn ống xoắn ốc. Nếu sử dụng lớp lót, thì chỉ có một lớp.

- Lớp trung gian – Lớp trung gian nằm giữa lớp lót và lớp bọc. Ống giấy có thể có nhiều lớp trung gian.

- Lớp dọc hoặc lớp OD – Lớp lót nằm trên đường kính ngoài và là lớp cuối cùng được quấn quanh trục trong quá trình quấn ống xoắn ốc. Nếu sử dụng lớp bọc, thì chỉ có một lớp.

Lõi giấy có thể được chế tạo chỉ bằng giấy kraft hoặc bìa cứng trong mỗi lớp hoặc bằng cách kết hợp các vật liệu khác nhau cho lớp lót và lớp bọc. Ví dụ, lớp lót có thể được làm bằng lá kim loại để tạo thành lớp chắn ẩm, lớp trung gian có thể là giấy kraft để tăng thêm độ bền và lớp bọc ngoài có thể bao gồm giấy trắng để dán nhãn in. Có thể sử dụng nhiều sự kết hợp vật liệu khác nhau cho lớp lót, lớp trung gian và lớp bọc.

Vật liệu lót và bọc có thể bao gồm:

- Giấy tráng men màu

- Nhãn giấy bạc

- Giấy thủy tinh hoặc giấy sáp

- Giấy có nhãn và đồ họa in

- Giấy kraft trơn

- Bìa cứng trơn

- Nhựa (polyester, polyethylene, polypropylene) được ép thành kraft

- Giấy bạc nhiều lớp nhựa

- Giấy tráng silicon

- Giấy bạc nhiều lớp vinyl

- Giấy kraft trắng, nâu, kim loại, màu hoặc đen

Bằng cách tận dụng khả năng bao gồm các lớp không phải giấy độc đáo trong quá trình sản xuất ống giấy, bạn sẽ thấy rằng có thể tạo ra một số vật liệu rất thú vị và hiệu suất cao.

Để cách điện, chống thấm nước, cách nhiệt, độ bền cơ học và các đặc tính khác cho các ứng dụng chuyên biệt, ống giấy có thể được sản xuất từ các lớp vật liệu không phải giấy.

Các vật liệu kỹ thuật có thể được quấn ngoài hoặc thay thế cho các lớp giấy thông thường hoặc giấy làm từ cellulose để cung cấp các đặc tính chuyên biệt cho các ứng dụng cụ thể. Ví dụ, các ống chuyên dụng có thể bao gồm:

- Ống giấy cấp thực phẩm được làm bằng lớp lót và lớp bọc màng nhựa và lá bảo vệ, có khả năng chống nước cao.

- Ống giấy cấp điện được chế tạo bằng cách sử dụng các lớp giấy cách điện, giấy kraft điện môi, giấy cá, aramid, sợi thủy tinh E, sợi vô cơ và các vật liệu điện môi khác.

- Ống giấy cấp chống ăn mòn hoặc chống gỉ hoặc ống giấy VCI có lớp lót bằng giấy ức chế ăn mòn pha hơi (VCI), giải phóng chất dễ bay hơi vào trong bình chứa hoặc ống giấy, bảo vệ chống gỉ và ăn mòn trong môi trường ẩm ướt. Ống giấy lót VCI sẽ bảo vệ thanh thép, thanh thép, góc thép, kênh thép, nòng súng, trục thép và các loại thép khác cũng như các hình dạng thép chế tạo khỏi bị ăn mòn.

|

Vật liệu ply đặc biệt bao gồm:

- Aramid (Nomex hoặc Kevlar)

- Giấy crepe điện môi

- Giấy Kraft điện môi

- Xốp

- Giấy làm từ sợi thủy tinh hoặc sợi vô cơ (CeQUIN® hoặc ParaQUIN ENV)

- Vật liệu giống da

- Ống giấy mica

- Giấy da

- Giấy kraft tẩm phenolic

- Vật liệu có kết cấu

- Giấy chống gỉ hoặc VCI

- Sợi lưu hóa hoặc giấy cá

- Vải dệt hoặc hàng dệt may

Thông thường, chất kết dính cho ống giấy dựa trên polyme gốc nước, polyvinyl alcohol, dextrin hoặc polyme nóng chảy. Một số chất kết dính có thể được biến đổi bằng đất sét hoặc các chất độn khác. Nếu sử dụng giấy không xenlulo chuyên dụng hoặc vải không dệt trong quá trình chế tạo ống giấy, có thể cần đến chất kết dính chuyên dụng hoặc nhựa nhiệt rắn để liên kết các lớp. Ngoài ra, ống giấy có thể được tẩm sáp, nhựa, silicon hoặc các polyme khác để tăng khả năng chống nước hoặc biến đổi các đặc tính cơ học và điện.

|

Ống giấy được chỉ định và đặt hàng như thế nào?

Thông số kỹ thuật về kích thước ống giấy

Ống giấy được đo và chỉ định dựa trên đường kính trong (ID), độ dày thành và chiều dài của chúng. Đối với các ứng dụng đóng gói hoặc chứa đựng, ID và chiều dài phải tương ứng với kích thước của sản phẩm được đóng gói.

Sản phẩm được đóng gói phải vừa khít trong ống để tránh bị xê dịch trong quá trình vận chuyển, đồng thời vẫn để đủ khoảng hở giữa sản phẩm và đường kính trong (ID) của ống để đảm bảo dễ dàng đưa vào.

Đối với các sản phẩm như bột, hạt, hóa chất hoặc mỡ, thể tích cần thiết cho mỗi hộp ống giấy sẽ xác định kích thước cần thiết. Đường kính ngoài ít quan trọng hơn đối với ống gửi thư hoặc bất kỳ hộp ống giấy nào.

Tóm lại, độ dày thành của ống giấy ảnh hưởng đến khả năng chống nghiền phẳng của nó. Ống phải đủ dày để tránh bị nghiền trong quá trình vận chuyển, xử lý và lưu trữ, nhưng không quá dày đến mức làm tăng chi phí và làm giảm lợi ích về trọng lượng nhẹ khi sử dụng ống giấy.

Lõi giấy được sử dụng trong quá trình chuyển đổi nặng thường cần thành dày hơn để chịu được ứng suất từ quá trình cuộn. Độ dày thành yêu cầu phụ thuộc vào chiều rộng và đường kính của vật liệu cuộn. Ví dụ, một cuộn băng dính hẹp để đóng gói bán lẻ có thể sử dụng thành mỏng hơn, trong khi lõi giấy để quấn một cuộn băng dính, màng, giấy hoặc vải lớn được chuyển đổi từ cuộn lớn yêu cầu thành dày hơn.

Kích thước của khuôn bê tông hoặc ống cọc được xác định theo đường kính yêu cầu của cọc bê tông hoặc giá đỡ. Thông thường, ống giấy có đường kính trong (ID) lớn được chỉ định cho các ứng dụng này.

Dung sai kích thước cũng là một cân nhắc quan trọng. Chỉ nên chỉ định dung sai chặt chẽ nếu thực sự cần thiết cho ứng dụng, vì việc chỉ định quá mức có thể làm tăng chi phí không cần thiết. May mắn thay, ống giấy và lõi được tạo thành trên một trục thép, giúp kiểm soát tuyệt vời đường kính trong (ID) của ống.

Ống giấy và lõi có thể hấp thụ và giải phóng độ ẩm theo thời gian, dẫn đến co ngót, giãn nở hoặc thay đổi kích thước của chúng. Độ ổn định về kích thước phụ thuộc vào khả năng chống hấp thụ độ ẩm hoặc khô của ống.

Ống cắt bằng lưỡi có thể duy trì dung sai chặt chẽ hơn nhiều so với ống cắt bằng cưa, điều này rất quan trọng khi ống giấy được sử dụng để tạo khoảng cách, che chắn hoặc bảo vệ ren, trục, trục chính và các thành phần cơ khí khác. Sự khác biệt giữa các cạnh cắt bằng lưỡi mịn và các cạnh cắt bằng cưa thô được thể hiện rõ trong hình ảnh.

|

Hiểu được năng lực của các nhà sản xuất ống giấy có thể giúp xác định kích thước nào khả dụng và khả thi. Bảng trên đánh giá năng lực sản xuất của một số nhà cung cấp ống giấy và lõi hàng đầu. Sau đây là tóm tắt về năng lực sản xuất theo kích thước của các nhà cung cấp hàng đầu này:

- Kích thước ống giấy hoặc lõi ID nhỏ nhất khả dụng là ¼ inch (0,25 inch)

- Kích thước ống giấy hoặc lõi ID lớn nhất khả dụng là 30 inch (2 ½ feet)

- Kích thước ống giấy hoặc lõi có độ dày thành nhỏ nhất khả dụng là 0,018 inch.

- Kích thước ống giấy hoặc lõi có độ dày thành lớn nhất khả dụng là 0,75 inch.

- Kích thước ống giấy hoặc lõi ngắn nhất khả dụng là ¼ inch (0,25 inch)

- Kích thước ống giấy hoặc lõi dài nhất khả dụng là 350 inch (khoảng 29 feet)

Mặc dù bảng hiển thị phạm vi kích thước khả dụng, nhưng điều cần thiết là phải liên hệ với nhà sản xuất để xác nhận xem họ có thể sản xuất ống giấy có kích thước cụ thể của bạn trên máy quấn và máy cắt của họ hay không. Ví dụ, ống giấy có đường kính trong là 0,25 inch, độ dày thành ống là 0,75 inch và chiều dài là 0,375 inch có thể không khả thi.

Ngay cả khi dự án của bạn nằm ngoài khả năng hiện tại của nhà sản xuất, bạn vẫn có thể mua và khấu hao máy móc hoặc dụng cụ mới cho các dự án khối lượng lớn với số lượng đặt hàng hàng năm đủ lớn. Dụng cụ ống giấy thường rẻ hơn dụng cụ cho các quy trình sản xuất khác, chẳng hạn như ép phun hoặc đùn.

Khi đặt hàng ống giấy, lõi giấy hoặc các sản phẩm ống giấy khác, điều quan trọng là phải thảo luận về mục đích sử dụng cuối cùng hoặc ứng dụng với nhà sản xuất. Các kỹ sư và chuyên gia của họ có thể đề xuất các yêu cầu về vật liệu và độ bền phù hợp (chẳng hạn như khả năng chịu nén phẳng, chịu nén xuyên tâm, chịu động hoặc chịu nổ), cũng như bất kỳ tính năng hoặc sửa đổi bổ sung nào cần thiết để đáp ứng nhu cầu ứng dụng cụ thể của bạn.

Ví dụ, ống khuôn bê tông giấy phải chịu được trọng lượng của bê tông lỏng. Nếu bạn đổ bê tông ở độ sâu lớn hơn, độ dày thành ống và độ bền của ống phải đủ để chịu được áp suất tăng lên.

Thông thường, ống định hình cấp thương mại có thể chịu được độ sâu đổ bê tông lên đến 20 feet, trong khi ống cấp nhà thầu phù hợp với độ sâu đổ bê tông lên đến 12 feet. Ống định hình bê tông có đường kính lên đến 60 inch, nhưng kích thước phổ biến nhất là 6, 8, 12, 15, 16, 18, 20, 24 và 36 inch.

Lõi giấy để chuyển đổi hoặc cuộn vật liệu thành cuộn thường có đường kính trong là 3 hoặc 6 inch và có nhiều mức hiệu suất hoặc độ bền khác nhau. Lõi có độ bền cao hơn hoặc cấp cao hơn phù hợp với kích thước cuộn thành phẩm lớn hơn, cuộn nặng hơn và tốc độ cuộn hoặc tháo cuộn cao hơn.

Tính chất và thử nghiệm ống giấy

Khả năng hấp thụ độ ẩm và khả năng chống nước có thể là những tính chất quan trọng đối với nhiều ứng dụng. Thử nghiệm Cobb thường được sử dụng để đo các tính chất hấp thụ độ ẩm của giấy. Độ ổn định về kích thước của ống giấy do khả năng chống hấp thụ hoặc giải phóng độ ẩm (khô) là một tính chất quan trọng khác.

Co ngót hoặc phồng lên có thể khiến các sản phẩm giấy bị cong vênh hoặc biến dạng, điều này sẽ gây rắc rối trong các ứng dụng lõi giấy khi vật liệu đang được cuộn lại. Một ống bị cong, vênh hoặc không tròn sẽ tạo ra nếp nhăn và các khuyết tật khác trên vật liệu cuộn như băng dính, giấy, màng nhựa hoặc giấy bạc.

Một cuộc khảo sát của TAPPI chỉ ra rằng 50% các vết đứt cuộn giấy trong các nhà máy giấy là do lỗi cuộn hoặc lõi. Một lượng lớn vật liệu có thể nhanh chóng trở thành chất thải nếu độ thẳng, độ tròn và độ bền của lõi giấy không nằm trong các thông số kỹ thuật cần thiết cho ứng dụng.

|

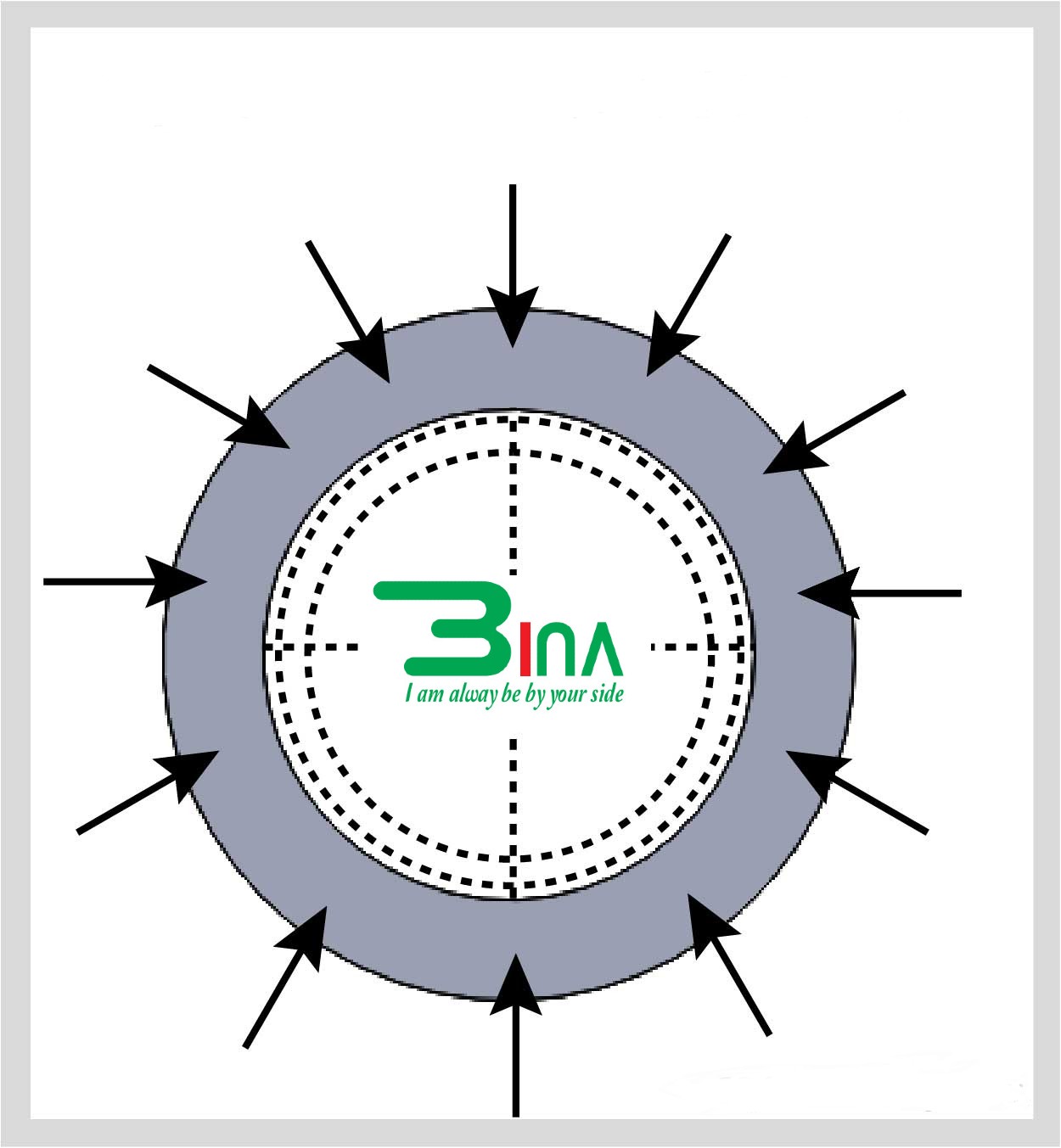

Lõi giấy chịu lực hướng tâm

Độ mịn và các rãnh từ quá trình cuộn xoắn ốc có thể tạo ra nếp nhăn trong quá trình cuộn cuộn. Các gờ bên ngoài từ quá trình cắt bằng cưa cũng có thể tạo ra nếp nhăn. Để giảm nếp nhăn, bạn có thể yêu cầu mài và đánh bóng bề mặt lõi giấy bên ngoài để tăng độ mịn.

Độ mịn có thể ảnh hưởng đến mức độ dễ dàng xoay của lõi chuyển đổi nhỏ trên trục chính trong quá trình phân phối. Các gờ trên các cạnh ống bên trong cũng có thể là yếu tố khiến lõi được đưa vào máy. Các gờ có thể mắc vào phích cắm hoặc đầu kẹp lõi khiến việc lắp lõi trở nên khó khăn. Độ mịn và gờ có thể được xác định bằng cách kiểm tra trực quan, chạm và đo độ nhám bề mặt.

Lõi giấy chất lượng thấp có thể khiến các cuộn giấy bị đứt và nổ, có thể khiến nhà máy giấy hoặc nhà máy sản xuất màng nhựa mất hàng nghìn đô la và có thể làm hỏng thiết bị và gây hại cho công nhân. Một số thử nghiệm cơ học khác nhau được sử dụng để đo độ bền và tính phù hợp của ống giấy và lõi giấy cho các ứng dụng cụ thể bao gồm thử nghiệm ép phẳng hoặc ép ngang, ép xuyên tâm, uốn cong hoặc uốn, thử nghiệm vòng và thử nghiệm tải động.

CCTI T-150 – Độ cứng uốn

Các phương pháp thử nghiệm công nghiệp trong tiêu chuẩn này được chia thành hai phần. Phần một xác định mô đun uốn và Độ cứng uốn của giấy bằng cách sử dụng phân tích mô thức và quy trình thử nghiệm uốn ba điểm. Phần hai cung cấp phương pháp tính toán tốc độ tới hạn lý thuyết của lõi giấy được sử dụng trên máy in và máy biến đổi web tốc độ cao.

Các thử nghiệm về hiệu suất chịu ứng suất uốn và rung động trục trong quá trình cuộn và tháo cuộn vật liệu web. Độ cứng uốn cũng là một yếu tố dự báo khả năng chống nổ lõi. Các thử nghiệm về độ bền uốn hoặc độ bền uốn đo khả năng chống lại tình trạng lõi giấy bị võng xuống dưới tải trọng tác dụng vào tâm của chiều dài. Lõi bị võng hoặc biến dạng có thể gây ra rung động và làm biến dạng các cuộn giấy.

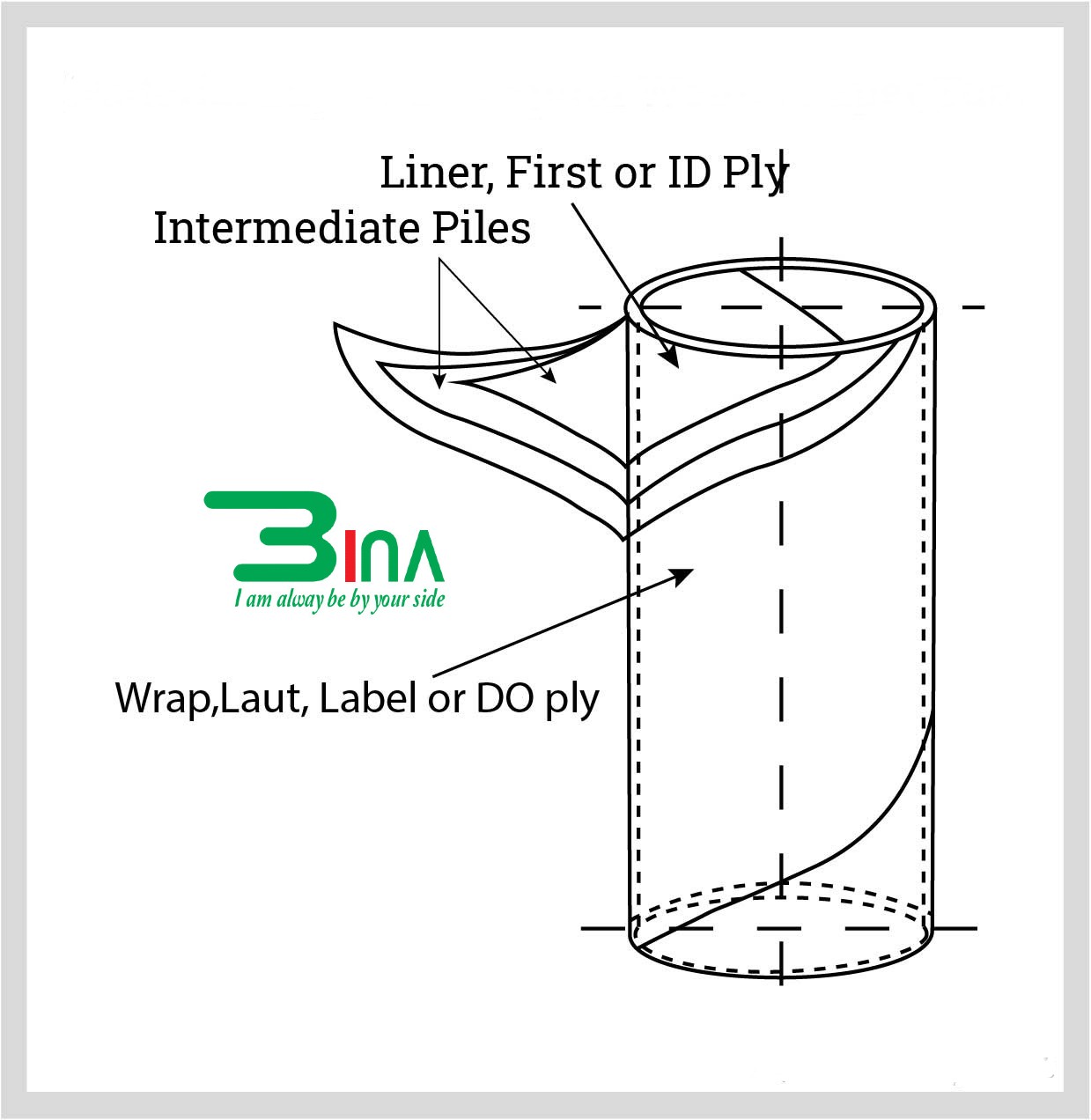

Thử nghiệm nghiền phẳng CCTI-108 từ bên này sang bên kia

Các thử nghiệm về hiệu suất nghiền của ống giấy hoặc lõi giấy trong quá trình xử lý và vận chuyển cuộn giấy quấn quanh lõi giấy. Các thử nghiệm về độ bền nghiền phẳng đẩy hai tấm phẳng hoặc đe vào thành ngoài của ống để đo độ bền nghiền. Độ bền nghiền phẳng hữu ích cho ống giấy và lon composite dùng trong các ứng dụng đóng gói. Đối với lõi giấy, thử nghiệm nghiền xuyên tâm mô phỏng tốt hơn các điều kiện tải trong quá trình cuộn.

Thử nghiệm tải động CCTI T-149

Thử nghiệm hiệu suất chịu tải hình trụ trong quá trình cuộn và tháo cuộn tại các nhà máy giấy, nhà máy màng nhựa và các cơ sở sản xuất web khác. Thử nghiệm độ bền động đo trọng lượng cuộn tối đa mà lõi có thể chịu được giữa các kẹp lõi về tuổi thọ hoặc số vòng quay.

Theo kinh nghiệm của tôi, tôi thấy rằng vật liệu thường hỏng ở ứng suất hoặc tải thấp hơn khi điều kiện tải tuần hoàn so với tải tĩnh. Thử nghiệm tải động hoặc độ bền động mô phỏng tác động của tải tuần hoàn do lực căng và vòng quay tốc độ cao của cuộn trong quátrình cuộn.

Khả năng chống nhai của kẹp tĩnh CCTI T-156

Các cuộn giấy, màng và vật liệu lớn khác tạo ra một lượng động lượng cực lớn trong quá trình cuộn. Khi các cuộn được tăng tốc hoặc phanh, mô-men xoắn được truyền đến lõi thông qua kẹp lõi và lực căng của web, cuối cùng dẫn đến việc cắn lõi hoặc xé toạc đường kính bên trong của lõi bởi kẹp. Tôi tin rằng việc cắn là một khu vực cần cải thiện các phương pháp thử nghiệm.

Ống giấy được sử dụng như thế nào?

Mục đích sử dụng và ứng dụng của ống giấy: Nhiều ngành công nghiệp khác nhau sử dụng ống giấy để đáp ứng một số chức năng sử dụng khác nhau bao gồm:

- Chứa & Đóng gói

- Tạo hình & Xây dựng

- Cách nhiệt & Làm ẩm

- Bảo vệ

- Khoảng cách

- Hỗ trợ & Giữ

- Cuộn & Mang

Chứa và Đóng gói

Chứa và đóng gói có lẽ là phân khúc ứng dụng lớn nhất đối với ống giấy. Ống gửi thư hoặc vận chuyển được sử dụng để đóng gói các tài liệu lớn có thể gấp lại như bản đồ, áp phích, bản in tác phẩm nghệ thuật, tranh gốc, bản thiết kế hoặc bản vẽ kỹ thuật và bản vẽ kiến trúc.

Ống bột được thiết kế để đựng hàng khô và vật liệu dạng hạt. Chúng thường có nắp lắc quay hoặc rây để hỗ trợ phân phối, tương tự như bình đựng muối và hạt tiêu dùng một lần.

Nước chanh đông lạnh và bột bánh quy được đóng gói trong hộp giấy dùng cho thực phẩm, có lớp lót và đầu bịt kín để đảm bảo chứa an toàn các sản phẩm thực phẩm. Ống dạng ống lồng thường được sử dụng để đóng gói chai rượu, nước hoa và mỹ phẩm.

Ống đẩy có lớp lót chống dầu lý tưởng để đựng son dưỡng môi, mỡ bôi trơn, keo chèn, keo dán, chất khử mùi và hợp chất sửa chữa.

Hóa chất, thành phần dược phẩm hoạt tính, thuốc trừ sâu và phân bón có thể được đóng gói trong hộp giấy và thùng composite bằng cách lót một túi nhựa vào hộp đựng trước.

Tạo hình & Xây dựng

Một ứng dụng khác mà tôi thấy đặc biệt hấp dẫn là sử dụng ống giấy trong xây dựng. Ống giấy xoắn đường kính lớn được sử dụng để tạo thành cọc bê tông bằng cách đổ bê tông vào ống, thường bao gồm cốt thép và lưới để gia cố. Ống chốt giấy đường kính nhỏ hơn được sử dụng để tạo lỗ rỗng hoặc kênh trong bê tông đúc, tạo không gian cho cáp thông tin liên lạc, hệ thống dây điện và hệ thống ống nước. Ngoài ra, một số kiến trúc sư đã khám phá việc sử dụng ống giấy làm vật liệu đóng khung cho nơi trú ẩn khẩn cấp hoặc tạm thời.

Cách nhiệt và giảm chấn

Ống giấy làm giảm rung động một cách tự nhiên nhờ cấu trúc dạng sợi của bìa cứng. Ngoài ra, chúng còn có khả năng cách nhiệt vượt trội so với ống kim loại.

Có thể sử dụng giấy crepe hoặc giấy kraft chuyên dụng để tạo ra ống giấy cách điện hoặc cách điện. Giấy kỹ thuật và bão hòa với nhựa được pha chế đặc biệt có thể tăng cường tính dẫn nhiệt hoặc tính cách điện.

Bảo vệ và che chắn

Ống giấy được sử dụng để bảo vệ nhiều thành phần cơ khí khác nhau, bao gồm trục chính, ren bu lông, trục đánh bóng, răng máy phay, thước đo chốt và mũi khoan. Bằng cách che các trục chính hoặc ren bu lông bằng ống bảo vệ, bạn có thể ngăn ngừa tác động từ các bộ phận kim loại khác có thể làm xước hoặc biến dạng ren.

Mặt nạ ống giấy được trượt trên các ren hoặc trục để có thể phủ lớp phủ hoặc chất kết dính có mục tiêu trong khi bảo vệ các khu vực được mặt nạ phủ không bị phủ.

Khoảng cách và hỗ trợ

Ống giấy đóng vai trò là cột trưng bày để hỗ trợ các biển báo trong cửa hàng và triển lãm. Chúng cũng được sử dụng làm miếng đệm trong bao bì để ngăn chuyển động và bảo vệ sản phẩm khỏi bị hư hỏng. Ví dụ, miếng đệm ống giấy được sử dụng để định vị và bảo vệ trục bánh xe ô tô trong quá trình vận chuyển. Ngoài ra, các miếng đệm ống giấy có thể hoạt động như các trụ góc gia cố và giá đỡ trong nhiều gói khác nhau.

Lõi cuộn

Lõi giấy, nón giấy và ống cuộn giấy thường được sử dụng để cuộn, mang và phân phối các vật liệu như dây, cáp, ống, lá, sợi, dây thừng và các vật liệu cuộn khác. Một ống cuộn giấy thường có lõi giấy với hai mặt bích bằng ván dăm. Trong ngành nông nghiệp, lõi giấy thậm chí còn được sử dụng để cuộn cỏ.

Ưu điểm và nhược điểm của ống giấy và lõi là gì

Ống giấy và lõi có một số ưu điểm so với ống nhựa hoặc ống kim loại:

- Chi phí thấp – Giấy có chi phí thấp hơn nhiều so với nhựa, thủy tinh và kim loại

- Trọng lượng nhẹ – Ống giấy bao gồm vật liệu nhẹ với mật độ thấp hơn hầu hết các vật liệu đóng gói khác. Giấy kraft chưa tẩy trắng có mật độ từ 36 đến 43 lb/ft³ (0,58 đến 0,69 g/cm³) trong khi nhôm, kim loại nhẹ nhất được sử dụng trong bao bì, có mật độ là 168 lb/ft³ (2,7 g/cm³), thủy tinh đóng chai soda lime có mật độ là 157 lb/ft³ (2,5 g/cm³), nhựa đóng gói thông thường (PE, PP và PET) có mật độ từ 56 đến 87 lb/ft³ (0,9 đến 1,4 g/cm³.

- Bền và chống va đập – Ống giấy bền và chống va đập so với vật liệu đóng gói như thủy tinh và một số loại nhựa. Hộp đựng ống giấy được sử dụng để bảo vệ rượu vang và các loại chai khác khỏi va đập.

- Dễ in hơn – Giấy dễ in đồ họa và nhãn hơn so với thủy tinh, nhựa hoặc kim loại, có thể cần lớp phủ, xử lý đặc biệt hoặc nhãn giấy

- Chặn ánh sáng – Hộp đựng ống giấy đục hoặc không trong suốt và có thể chặn ánh sáng mặt trời bảo vệ thực phẩm, rượu vang, đồ uống, thuốc và các hàng hóa nhạy sáng khác

- Bền vững & Thân thiện với môi trường – Ống giấy được làm từ 100% sản phẩm giấy tái chế và có thể tái chế

- Công nghệ đã được chứng minh & phát triển – Các quy trình sản xuất, tiêu chuẩn và thông lệ được thiết lập tốt được sử dụng để kiểm soát công nghệ sản xuất ống giấy và lõi giấy. Ngành công nghiệp giấy và chuyển đổi không ngừng phát triển, phát triển các công nghệ mới, các phương pháp hiệu quả hơn để giảm mức tiêu thụ năng lượng và chất thải.

Ống giấy và lõi giấy có những nhược điểm so với các sản phẩm tương tự làm từ kim loại, nhựa hoặc thủy tinh:

- Không thấm nước – Không giống như nhựa, thủy tinh và kim loại, ống giấy có thể hấp thụ nước và độ ẩm trong môi trường ẩm ướt

- Độ ổn định về kích thước – Việc hấp thụ độ ẩm hoặc giải phóng độ ẩm có thể gây ra những thay đổi về kích thước và biến dạng hoặc cong vênh

- Độ bền thấp hơn – Ống giấy và lõi giấy không bền bằng kim loại có độ bền cao, sợi thủy tinh hoặc nhựa kỹ thuật

- Bụi / Rách – Các cạnh cắt có thể tạo ra bụi. Giấy có thể bị sờn hoặc rách theo thời gian.

- Chew-out – Các đầu lõi có thể bị “chew-out” sau thời gian sử dụng kéo dài và tải trọng cao

- Không trong suốt – Khách hàng không thể nhìn xuyên qua hộp đựng ống giấy và xem sản phẩm trừ khi thêm cửa sổ vào hộp đựng

Tái chế và tính bền vững

Các ngành công nghiệp ngày càng áp dụng các giải pháp đóng gói thân thiện với môi trường và bền vững, như ống giấy, để giảm lượng khí thải carbon và nâng cao hình ảnh của họ với khách hàng. Nhiều người tiêu dùng ưa chuộng bao bì thân thiện với môi trường, điều này có thể ảnh hưởng đến quyết định mua hàng của họ.

Những lợi ích về tiếp thị, sự chấp nhận của người tiêu dùng và chi phí của ống giấy trong bao bì và lựa chọn sản phẩm là rõ ràng. Ngoài ra, việc sử dụng ống giấy có thể giúp giảm chi phí liên quan đến việc tuân thủ các quy định về môi trường đối với nhựa và kim loại, vì chúng không chứa hợp chất hữu cơ dễ bay hơi (VOC) và kim loại nặng, thường được quản lý.

Khách hàng mua sản phẩm ống giấy phải quan tâm đến việc tuân thủ:

- Thông báo theo Đề xuất 65 của California tại Hoa Kỳ

- Quy định REACH của EU

- Giới hạn kim loại nặng của Quy định về chất độc hại trong bao bì của Hoa Kỳ

- Điều 11 của Chỉ thị 94/62/EC của EU.

Sản xuất ống giấy và lõi giấy là một quy trình rất thân thiện với môi trường và bền vững vì một số lý do:

- Nguyên liệu thô bền vững và có thể tái tạo – giấy và bìa cứng có nguồn gốc từ gỗ, xenluloza và thực vật, có thể được thu hoạch và trồng lại một cách bền vững.

- Tái chế chất thải và chất thải của khách hàng – Phế liệu từ quá trình sản xuất và lõi giấy, ống giấy, giấy và bìa cứng bị loại bỏ được gửi trở lại các nhà máy giấy và tái chế, giúp giảm lượng tiêu thụ bột giấy nguyên chất.

- Chương trình thu gom và tái sử dụng – Nhiều nhà sản xuất ống giấy có chương trình thu gom và tái sử dụng ống giấy và lõi giấy để tạo điều kiện thu gom lõi đã qua sử dụng từ khách hàng cũng như giấy và bìa cứng phế liệu từ cộng đồng của họ.

Các nhà sản xuất ống giấy giúp đạt được các mục tiêu bền vững:

- 100% tái chế – Nhiều nhà sản xuất ống giấy và lõi giấy sử dụng 100% vật liệu tái chế, được làm từ lõi giấy, ống giấy, giấy và bìa cứng bị loại bỏ.

- Giảm khí nhà kính – Khi bao bì ống giấy thay thế bao bì nhựa và kim loại, lượng khí nhà kính thải ra khí quyển sẽ ít hơn. Trong khi quá trình chế biến giấy tạo ra một số khí nhà kính, thì sản xuất kim loại và nhựa tạo ra nhiều hơn thế nữa. Ngoài ra, sự phát triển của cây cối và quản lý lâm nghiệp giúp thu giữ khí nhà kính.

- Khả năng phân hủy sinh học – Ống và lõi giấy có khả năng phân hủy sinh học, do đó, bất kỳ phế liệu hoặc ống đã qua sử dụng nào không qua tái chế và thải ra bãi rác đều sẽ phân hủy mà không gây hại cho môi trường.

- Vật liệu tự nhiên/an toàn với môi trường – Ống và lõi giấy được làm từ vật liệu thực vật tự nhiên và an toàn với môi trường vì chúng không chứa bất kỳ hóa chất độc hại hoặc kim loại nặng nào. Ống giấy chôn dưới đất sẽ phân hủy trong vòng 1 đến 2 tháng và bổ sung chất dinh dưỡng trở lại đất.

Kết luận về ống giấy:

- Độ dày và chiều dài thành ống là thông số kỹ thuật chính khi chỉ định và đặt hàng ống giấy và lõi giấy.

- Các nhà sản xuất ống giấy ngày nay sản xuất nhiều loại sản phẩm khác nhau bằng các phương pháp đã được kiểm nghiệm theo thời gian, liên tục được nâng cấp với các cải tiến công nghệ mới.

- Các chuyên gia sản xuất ống giấy biết cách lựa chọn các kết hợp vật liệu, đường kính, chiều dài, lớp hoàn thiện và đầu bịt cụ thể cho nhiều ứng dụng trong ngành.

- Các chuyên gia sản xuất ống giấy sẵn sàng hợp tác với khách hàng để phát triển các ứng dụng mới có thể hưởng lợi từ công nghệ ống giấy.

- Triển vọng sử dụng ống và lõi giấy ngày càng tăng là vô cùng hứa hẹn khi xét đến nhiều khả năng mà các nhà sản xuất ống và lõi giấy hiện đại có thể cung cấp cho khách hàng cũng như những lợi ích đối với môi trường.

Đánh giá

Chưa có đánh giá nào.