Mô tả

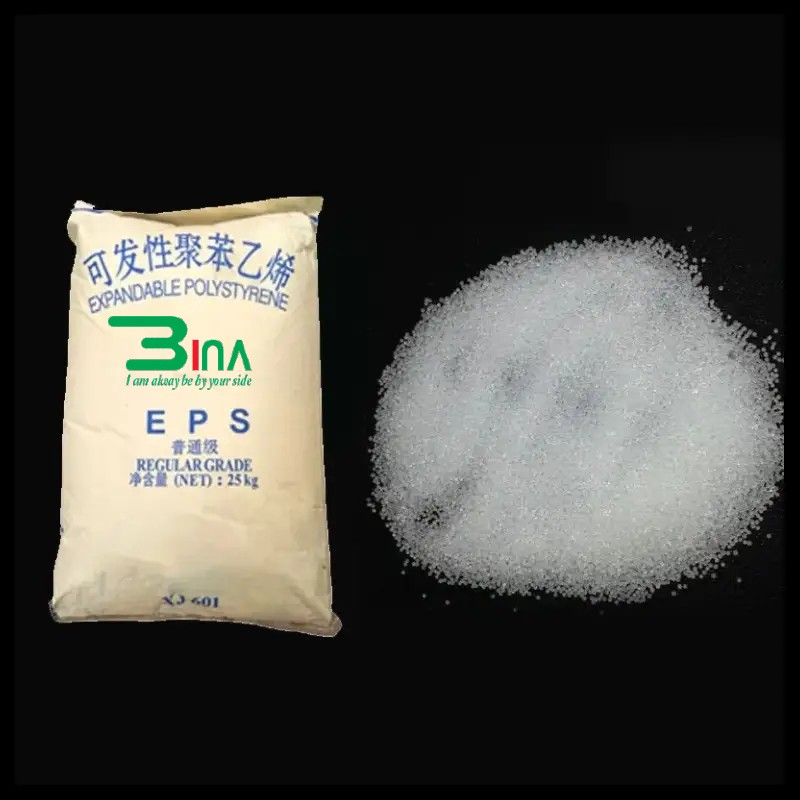

Hạt nhựa EPS là gì?

Polystyrene giãn nở (EPS) là vật liệu bọt nhiệt dẻo, ô kín, cứng được sản xuất từ các hạt polystyrene rắn, được trùng hợp từ monome styrene và chứa khí giãn nở (pentane) hòa tan trong hạt polystyrene.

Mỗi hạt polystyrene rắn chứa một lượng nhỏ khí giãn nở khi nhiệt (dưới dạng hơi nước) được áp dụng, do đó tạo thành các ô kín của EPS. Các ô giãn nở này chiếm khoảng 40 lần thể tích của hạt polystyrene ban đầu, do đó với quá trình xử lý nhiệt thứ hai bằng khuôn, các khối EPS lớn có thể được đúc thành các hình dạng tùy chỉnh cụ thể.

|

|

|

1. LỊCH SỬ

Sự phát triển thương mại của polystyrene ban đầu được IG Farben khởi xướng tại Đức vào năm 1929 và được công ty Dow Chemical Co. của Hoa Kỳ xây dựng vào khoảng năm 1935 (1). Mặc dù được sử dụng ở cả Đức và Hoa Kỳ trong suốt Thế chiến thứ hai, bọt polystyrene đã được Dow Chemical Co. giới thiệu rộng rãi hơn vào năm 1954 dưới tên thương hiệu ‘Styrofoam’. ‘Styrofoam’ – do nhà khoa học Ray McIntire của Dow phát minh – là kết quả của nỗ lực tạo ra một loại cao su mới bằng cách kết hợp styrene và isobtylene (2), nhưng khi làm như vậy, ông đã ‘vô tình’ tạo ra một loại bọt nhẹ hơn 30 lần và linh hoạt hơn nhiều so với polystyrene (3).

◆Tìm hiểu thêm:

- https://hadupack.com/san-pham/hat-nhua-pbt/

- https://hadupack.com/san-pham/hat-nhua-pla/

- https://hadupack.com/san-pham/hat-nhua-ps/

2. TÍNH CHẤT

- EPS có thể được đúc theo nhiều mật độ khác nhau, từ thấp nhất là 12kg/m3 đến 50kg/m3, với các tính chất kết quả, chẳng hạn như cường độ nén, được xác định bởi mật độ sản xuất.

- Các sản phẩm làm từ EPS thường có khả năng chống nước, bền và có khả năng chống va đập rất cao. Cấu trúc chứa đầy không khí có độ dẫn nhiệt ổn định lâu dài, không độc hại và trơ về mặt hóa học.

- Nấm và vi khuẩn không thể phát triển trên EPS do các tính chất của nó.

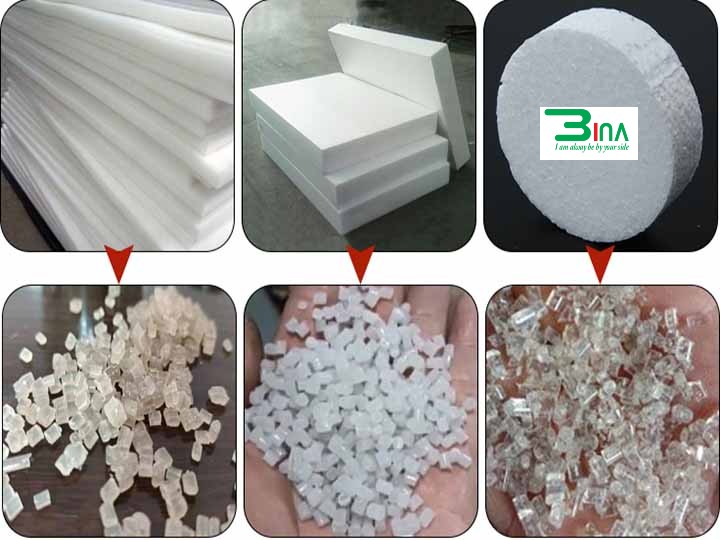

3. ĐÚC EPS

Sản xuất các sản phẩm làm từ EPS được thực hiện theo 3 giai đoạn…

1. Giãn nở trước:

- Một lượng hạt polystyrene giãn nở được đo lường được đưa vào máy tạo bọt

- Hơi nước được lưu thông qua các hạt này cũng như một lượng nhỏ (thường là khoảng 5% theo trọng lượng) petane là chất tạo bọt.

- Sau đó, các hạt được giãn nở khoảng 40 lần.

- Các hạt polystyrene giãn nở được chuyển vào phễu chứa…

2. Làm chín:

- Vật liệu nguội đi và pentan hóa lỏng tạo ra một phần chân không bên trong hạt

- Các hạt polystyrene giãn nở được lưu trữ trong khoảng từ 12-24 giờ để hỗ trợ quá trình trưởng thành và cho phép không khí khuếch tán vào các hạt

3. Tạo hình cuối cùng:

- Sau đó, các hạt được làm nóng lại bằng hơi nước và khuôn được đổ đầy một lượng hạt giãn nở được đo lường trước

- Hơi nước được đưa vào khuôn lưu thông xung quanh các hạt polystyrene, làm chúng giãn nở thêm 10%.

- Quá trình hấp dừng lại và chân không được tạo ra để trích xuất nước ngưng tụ còn lại và nhiệt. Các kênh nước bổ sung hỗ trợ làm mát khuôn

4. ỨNG DỤNG

4.1. ĐÓNG GÓI

Vì EPS được làm từ 98% không khí nên đây là một trong những vật liệu đóng gói nhẹ nhất hiện nay và do đó, trọng lượng đóng gói rất ít, nghĩa là chi phí vận chuyển và lượng khí thải nhiên liệu được giảm thiểu tối đa. Nó cũng cực kỳ hữu ích vì có thể đánh dấu rõ ràng bằng nội dung cụ thể như logo công ty và có thể dễ dàng dán nhãn trực tiếp lên bao bì.

Xốp polystyrene cũng rất bền và ma trận tế bào có khả năng chống va đập và hấp thụ sốc tuyệt vời để bảo vệ sản phẩm, khiến nó trở thành bao bì lý tưởng trong nhiều ứng dụng, bao gồm bảo vệ mọi loại linh kiện điện, từ điện thoại di động đến tủ lạnh-tủ đông.

Polystyrene giãn nở được sử dụng để đóng gói hàng hóa nhằm bảo vệ chúng trong quá trình vận chuyển

Nó cũng được sử dụng rộng rãi để bảo vệ thực phẩm và tránh hư hỏng trong nhiều giai đoạn sản xuất và vận chuyển thực phẩm do đặc tính không thể phát triển nấm và vi khuẩn. Độ dẫn nhiệt thấp của nó được sử dụng chủ yếu trong ngành công nghiệp cá để đóng gói và vận chuyển các sản phẩm cá, và trong lĩnh vực y tế để vận chuyển các cơ quan cấy ghép quan trọng.

4.2. XÂY DỰNG

Do khả năng cách nhiệt cao (từ cấu trúc ô kín nhẹ, độ bền và tính toàn vẹn về mặt kết cấu lâu dài), EPS đã được sử dụng trong các ứng dụng xây dựng từ trước những năm 1970.

EPS được sử dụng rộng rãi trong tường, mái và sàn, nơi cường độ nén của nó có thể được điều chỉnh cho các hệ thống cụ thể như kết cấu dầm và khối, hệ thống sưởi ấm dưới sàn và bên dưới các tấm sàn bê tông.

Nó cũng được chỉ định để lấp đầy khoảng trống và, ở mật độ cao hơn, làm nền cho các kè đường bộ hoặc đường sắt nơi vật liệu lấp đầy truyền thống quá nặng. Vật liệu này có lợi thế ở các trung tâm thành phố là giảm tắc nghẽn và giao thông với việc vận chuyển khối lượng lớn sản phẩm hiệu quả hơn so với vật liệu cứng.

Các ứng dụng chuyên biệt khác như bảo vệ nền móng cũng đã được phát triển.

5. THÔNG TIN VỀ MÔI TRƯỜNG

EPS có tác động carbon thấp vì công nghệ sản xuất sạch tương đương với lượng năng lượng và nước đầu vào tối thiểu mà không có chất thải sản xuất. Hiệu suất bảo vệ của EPS cũng giúp giảm lãng phí do hàng hóa bị vỡ hoặc hư hỏng trong chuỗi cung ứng, giúp tiết kiệm năng lượng, vật liệu và chi phí vận chuyển.

Việc sử dụng EPS cũng giúp ngăn ngừa lãng phí thực phẩm vì bản chất tế bào của nó, vì nó bảo vệ thực phẩm và tránh hư hỏng trong các giai đoạn sản xuất và vận chuyển khác nhau từ trang trại đến bàn ăn, đảm bảo nhiều loại thực phẩm khác nhau đến tay người bán lẻ hoặc người tiêu dùng trong tình trạng hoàn hảo.

EPS không chứa HFC, CFC và HCFC, với Pentane được sử dụng làm chất tạo bọt. Pentane có tiềm năng làm nóng toàn cầu (GWP) thấp dưới năm – nghĩa là EU không đăng ký pentane là chất gây nguy hiểm cho sức khỏe con người hoặc môi trường.

Vì EPS cực kỳ nhẹ nên nó giúp giảm mức tiêu thụ nhiên liệu – khi vận chuyển hàng hóa so với các vật liệu đóng gói nặng hơn khác.

Styrene, được sử dụng trong sản xuất EPS, có trong tự nhiên trong nhiều sản phẩm thông thường bao gồm dâu tây, đậu, hạt, bia, rượu vang, hạt cà phê và quế.

Sản xuất EPS là một quá trình ít gây ô nhiễm. Vì hơi nước là thành phần chính và nước được tái sử dụng nhiều lần. Không có chất thải trong quá trình này vì tất cả các phần cắt bỏ hoặc loại bỏ đều được tái sử dụng.

Chỉ có 0,1% tổng lượng dầu tiêu thụ được sử dụng để sản xuất EPS.

Lượng khí thải carbon của EPS thấp hơn nhiều vật liệu đóng gói khác đang được sử dụng hiện nay.

6. HẾT VÒNG ĐỜI

EPS có thể được thu hồi và tái chế thành công ở bất kỳ nơi nào có cơ sở tái chế EPS, ngày càng phổ biến từ thu hồi cơ học đến xử lý bằng dung môi, đưa polyme trở lại thành nguyên liệu thô. EPS, có nguồn gốc từ chất thải bao bì, là vật liệu lý tưởng cho các chương trình thu hồi. Ngày nay, nó chỉ chiếm 0,1% chất thải rắn đô thị (MSW), mặc dù nhiều người tin rằng nó lớn hơn nhiều do bản chất cồng kềnh của nó! Khi cơ sở hạ tầng tái chế hiện chưa có, thì đây là ứng cử viên lý tưởng để nộp đơn xin tham gia các chương trình năng lượng từ chất thải.

Lợi ích chính của việc sử dụng EPS cho EfW là nó có giá trị nhiệt cao (46.000 kj/kg) không khác gì khí đốt tự nhiên ở mức 48.000 kj/kg. Phương pháp quản lý chất thải EPS này cũng không phát thải chất độc hại vì nó được đốt trong các nhà máy hiện đại ở nhiệt độ rất cao. Do đó, các sản phẩm phụ chỉ là hơi nước, carbon dioxide và hàm lượng tro không độc hại rất thấp, ít gây ô nhiễm hơn so với lửa trại thông thường và trên thực tế không có bằng chứng đáng tin cậy nào cho thấy các chương trình EfW có bất kỳ tác động nào đến sức khỏe cộng đồng.

Phát thải EfW được kiểm soát chặt chẽ và ‘Chiến lược chất thải cho nước Anh năm 2007’ của Chính phủ Vương quốc Anh không thấy ‘bằng chứng đáng tin cậy nào về kết quả sức khỏe bất lợi’ từ phát thải EfW.

Đánh giá

Chưa có đánh giá nào.