Mô tả

Giấy duplex là gì?

Đây là thời đại của sự đổi mới và đơn giản hóa, cho mọi nhu cầu, chúng ta tìm kiếm các giải pháp đơn giản và thiết thực nhất. Do đó, giấy Duplex đã tăng thứ hạng nhờ thiết kế đơn giản và những cải tiến trong nhiều năm qua cũng như các ứng dụng thiết thực hàng ngày của nó. Một loại bìa cứng hoặc bìa cứng, bìa cứng duplex là một trong những khám phá chắc chắn nhất cho mục đích sử dụng hàng ngày.

Mặt ngoài của bìa cứng được phủ một lớp để chống thấm nước và đánh bóng tốt hơn, nhưng bìa cứng duplex không phủ vẫn đủ chắc

để làm cốc dùng một lần. Không giống như bìa cứng sóng, bìa cứng duplex cứng, nhẹ và có thể có màu trắng sáng.

◆Tìm hiểu thêm:

- https://hadupack.com/san-pham/giay-to-ong/

- https://hadupack.com/san-pham/ong-hut-giay/

- https://hadupack.com/san-pham/giay-ivory/

Cấu trúc của giấy Duplex

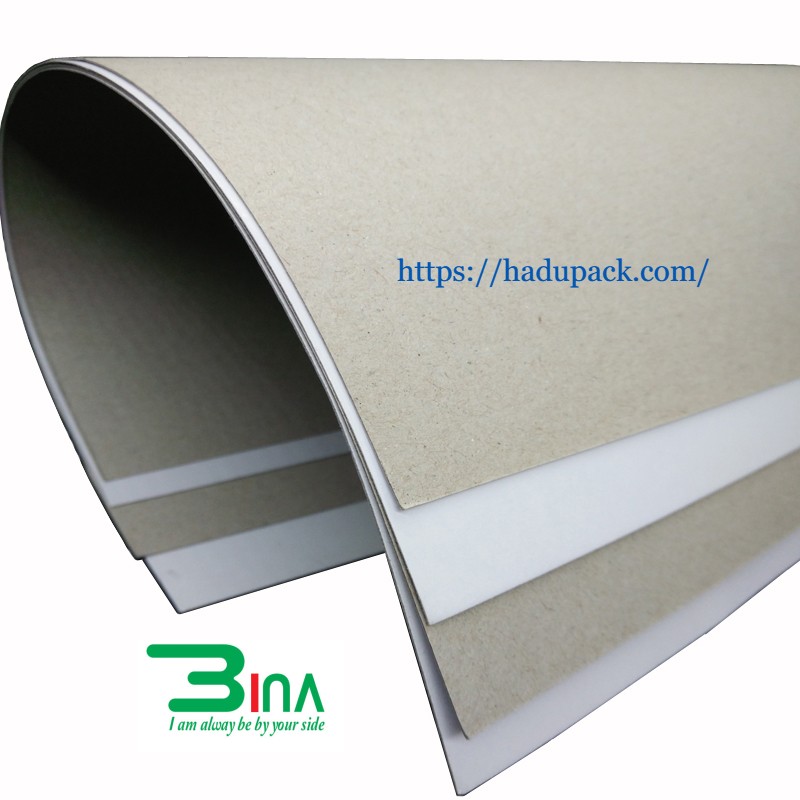

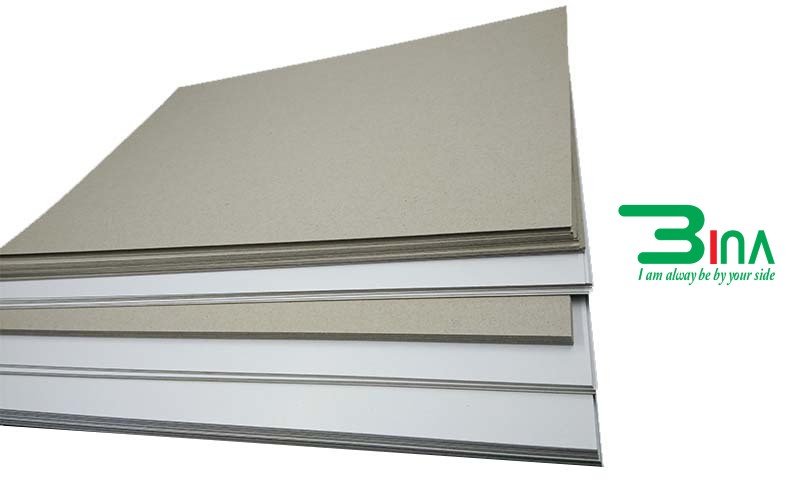

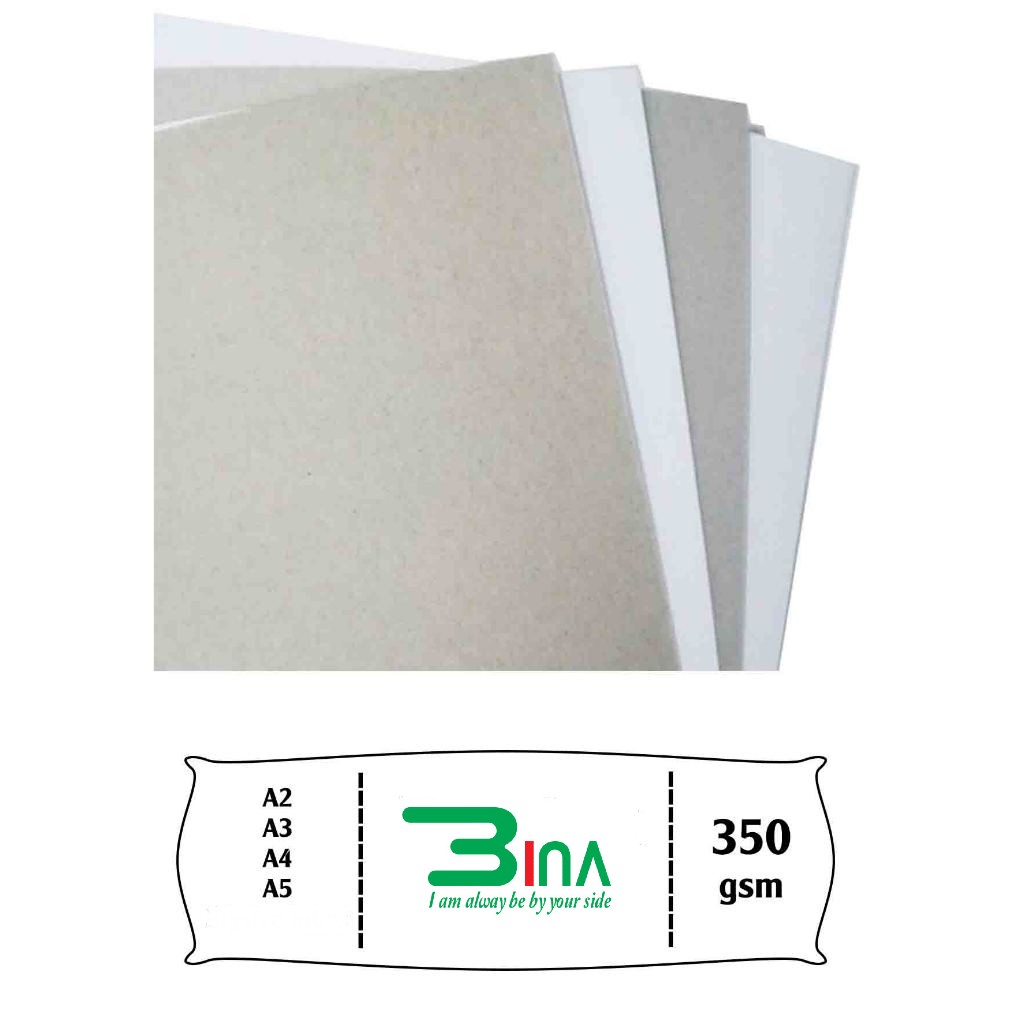

Được làm từ 100% bột gỗ, một mặt bìa cứng duplex có lớp lót tẩy trắng. Bìa cứng duplex, còn được gọi là bìa cứng duplex mặt sau màu xám hoặc mặt sau màu trắng, là một dạng bìa cứng hoặc bìa cứng có hai mặt màu xám hoặc trắng. Vì được tạo thành từ hai lớp hoặc lớp, nên nó được gọi là bìa cứng duplex. Tấm giấy Duplex có lớp phủ bóng ở một mặt để có khả năng in ấn vượt trội. Tùy thuộc

vào mục đích sử dụng, tấm Duplex có lớp phủ trọng lượng cao để sử dụng nhiều hoặc chắc chắn hơn và lớp phủ trọng lượng nhẹ để sử dụng ít.

Công thức nhiều lớp của Giấy được cấu trúc chính xác bằng bột giấy đã qua xử lý, giấy tái chế và bột giấy hữu cơ. Cấu trúc nhiều lớp của giấy Duplex Board tráng phủ giúp giấy bền với điều kiện sử dụng thô và không phù hợp theo thời gian.

Tính chất của tấm giấy Duplex

Tấm Duplex Board vì các ứng dụng cụ thể của nó có nhiều tính chất khác nhau giúp nhiều ngành công nghiệp thuận tiện sử dụng.

- Chống ẩm: Tấm Duplex Board được thiết kế để chống ẩm. Lớp phủ của tấm duplex board mang lại độ bóng cao cũng như chất lượng chống nước quan trọng đảm bảo lớp phủ của Giấy Duplex Board chống ẩm và các hạt.

- Chống cong vênh: Được thiết kế đặc biệt để đóng gói, tấm Duplex Board có tính chất Chống cong vênh để ngăn không cho tấm bị cong vênh, giúp tấm phù hợp để lưu trữ hoặc vận chuyển hàng hóa.

- Độ cứng: Giấy Duplex Board rất cứng và có cấu trúc cứng do thiết kế nhiều lớp, khiến chúng trở nên lý tưởng để đóng gói nhiều loại mặt hàng và không phải lo lắng về độ bền của vật liệu đóng gói.

- Khả năng chống gấp: Giấy Duplex Board có thể được định hình độc đáo theo bất kỳ hình dạng hoặc khuôn nào, nhưng chúng có khả năng chống gấp, khiến chúng phù hợp để gói và đóng gói.

- Lớp phủ đồng nhất: Giấy Duplex Board được phủ đồng nhất để có ứng dụng cao cấp và đồng đều. Do tính đồng nhất của nó, việc sử dụng nó không chỉ giới hạn ở bao bì và có thể được sử dụng rộng rãi trong các lĩnh vực khác.

- Bề mặt nhẵn hỗ trợ mọi loại in: Bề mặt nhẵn và đồng nhất của giấy Duplex Board giúp nó tương thích với mọi loại in, cho dù là in offset, in phun hay in laser.

Ứng dụng của giấy Duplex Board

Ứng dụng của giấy Duplex Board không bị giới hạn, trên thực tế, thiết kế và cấu trúc của nó cho phép nó được sử dụng trong ít nhiều bất kỳ lĩnh vực sản xuất, đóng gói hoặc ứng dụng thủ công nào. Tác động môi trường của giấy Duplex Board đã được cải thiện để tuân thủ các thông lệ bền vững nhất về mặt môi trường. Với những phát triển mới trong công nghệ hiện đại, những đột phá và nghiên cứu và

phát triển liên tục, các tấm ván đã có tác động sinh thái cân bằng. Hầu hết các tấm ván Duplex đều được làm từ các chất được chấp thuận cấp thực phẩm và đã được công nhận để sử dụng trong bao bì thực phẩm và thuốc.

Tấm ván Duplex được sử dụng trong nhiều ngành công nghiệp khác nhau bao gồm:

- Bao bì cho ngành đồ uống

- Hộp diêm

- Bao bì cho hàng may mặc

- Thùng carton đựng dược phẩm

- Thiệp chúc mừng

- Bao bì thực phẩm

- Và các nhu cầu đóng gói và thủ công khác.

Đây là tất cả những gì bạn cần biết về giấy Duplex Board, về cơ bản đã có mặt trong nhà chúng ta và xung quanh chúng ta nhờ chất lượng sử dụng đa năng tuyệt vời.

Đánh giá

Chưa có đánh giá nào.