Mô tả

In tem mã vạch là gì?

In tem mã vạch là loại tem nhãn có in mã vạch. Mã vạch đã trở thành một nhu cầu thiết yếu trong kinh doanh ngày nay. Thứ nhất, điều quan trọng đối với tổ chức của bạn là phải lưu giữ dữ liệu chính xác của tất cả hàng tồn kho, lô hàng và tài sản để có năng suất và lợi nhuận cao hơn. Tìm hiểu về mã vạch, lịch sử của nó và cách thức cũng như lý do chúng phát triển và sử dụng.

|

|

◆Tìm hiểu thêm:

- https://hadupack.com/san-pham/in-ruy-bang/

- https://hadupack.com/san-pham/in-tag-quan-ao/

- https://hadupack.com/san-pham/in-tem-bac/

Nhãn in là thành phần chính cho các mặt hàng cần được xác định nhanh chóng và dễ dàng. Nếu một sản phẩm hoặc mặt hàng cần được xác định nhanh chóng và hiệu quả, nhãn mã vạch nhiệt in sẽ là con đường tốt nhất cho doanh nghiệp của bạn. Từ in ấn khối lượng thấp đến các giải pháp toàn cầu của doanh nghiệp quy mô lớn, nhãn mã vạch chính là chìa khóa cho thành công và năng suất của bạn.

|

|

In nhãn mã vạch đòi hỏi phải thiết lập hệ thống dễ dàng. Hệ thống này sẽ có ba (3) thành phần chính: máy in, nhãn và ruy băng, và phần mềm/máy quét. Ngoài ra, quy mô doanh nghiệp của bạn, khối lượng in mà bạn yêu cầu và mặt hàng mà bạn muốn dán nhãn đều ảnh hưởng đến hệ thống nào sẽ phù hợp nhất với bạn. Bất kể quy mô hay mặt hàng, hệ thống mã vạch được thiết kế để hợp lý hóa năng suất của bạn. Lợi ích của việc sử dụng nhãn nhiệt mã vạch là vô tận, đặc biệt nếu bạn sử dụng chúng để đánh dấu hàng tồn kho, phân phối và vận chuyển, theo dõi tài sản, v.v.

|

|

Nhãn mã vạch và tiêu chuẩn GS1

Nhiều nhãn mã vạch được tạo ra hiện nay tuân thủ một trong các tiêu chuẩn do GS1 phát triển. GS1 là tổ chức phi lợi nhuận phát triển các tiêu chuẩn kinh doanh trong lĩnh vực truyền thông. Một số mã vạch đã được thiết lập từ các tiêu chuẩn do GS1 phát triển, bao gồm mã UPC-A, mã EAN-8 hoặc mã GS1 Datamatrix. Một số tiêu chuẩn quan trọng nhất do GS1 phát triển bao gồm:

- Mã số vị trí toàn cầu (GLN). Mã này có thể được sử dụng để xác định bất kỳ vị trí hợp pháp, vật lý và chức năng nào của nhà cung cấp. GLN có định dạng chuẩn hóa. Cấu trúc của mã này sao cho bất kỳ vị trí nào trên toàn thế giới đều có thể được xác định duy nhất và riêng biệt.

- Mã số bài viết châu Âu (EAN). Mã EAN được sử dụng để nhận dạng chéo các bài viết và sản phẩm có bất kỳ nguồn gốc nào (đơn vị tiêu dùng và đơn vị thương mại). Mã này chỉ cung cấp thông tin cho mục đích nhận dạng (không liên quan đến phân loại hoặc mô tả bài viết). Ngày nay, khoảng 250.000 doanh nghiệp sử dụng mã EAN do mạng lưới quốc tế gồm 59 đơn vị phát hành mã chính thức đại diện cho 65 quốc gia duy trì. Mã EAN và hệ thống mã vạch tương ứng cùng với mã UPC được sử dụng tại Hoa Kỳ hiện đang được sử dụng trên toàn thế giới.

- Mã container vận chuyển theo chuỗi (SSCC). SSCC được phát triển nhằm mục đích cung cấp khả năng nhận dạng từng container vận chuyển. Mã này tạo điều kiện thuận lợi cho việc cung cấp, phân phối và tiếp nhận các mặt hàng được đóng gói trong các container không chuẩn hóa. Là một mã nhận dạng thuần túy, SSCC, giống như mã EAN, cung cấp một số thông tin nhất định. Ngược lại với mã EAN được gán cho một mặt hàng cụ thể, SSCC không cung cấp thông tin về mặt hàng tương ứng. SSCC gồm 18 ký tự là cốt lõi của hệ thống GS1.

- Mã vạch GS1-128. Mã vạch này cho phép các tổ chức mã hóa thông tin chứa tối đa 40 thành phần trong một mã vạch duy nhất. Do đó, mã vạch có thể cung cấp thông tin liên quan đến nhận dạng (ví dụ: EAN, SSCC), theo dõi sản phẩm (ví dụ: SSCC, số lô), ngày tháng (ví dụ: ngày sản xuất, ngày hết hạn), đơn vị cân (ví dụ: trọng lượng tính bằng kilôgam), số tham chiếu (ví dụ: số đơn hàng của người nhận), ID công ty (ví dụ: ID công ty của người nhận) và mục đích sử dụng nội bộ.

|

|

Lợi ích của nhãn mã vạch tuân thủ GS1

Sử dụng nhãn mã vạch tuân thủ tiêu chuẩn GS1 có nhiều lợi thế, bao gồm:

- Chúng cho phép theo dõi liên tục các lô hàng từ người gửi đến người nhận.

- Chúng tạo điều kiện thuận lợi cho công việc của người gửi hàng vận chuyển hàng hóa hợp nhất.

- Nhãn mã vạch tuân thủ GS1 cung cấp nhiều thông tin hơn các mã vạch khác.

- Loại bỏ lỗi quét.

- Chúng cho phép kiểm tra xem lô hàng đã đầy đủ chưa và ngăn ngừa tình trạng dư thừa không phù hợp.

- Có thể thêm các ký tự kiểm soát bổ sung vào mã vạch (ví dụ: số đơn hàng, ngày hết hạn, kích thước lô).

Các quy định áp dụng cho nhãn tuân thủ GS1

- Nhãn tuân thủ GS1 phải tuân thủ một số quy định nhất định. Cụ thể, chiều dài, bao gồm cả các vùng trống, không được vượt quá 165 mm.

- Ngoài ký hiệu dữ liệu, không được có quá 48 ký tự dữ liệu người dùng. Trong trường hợp mã vạch GS1-128, không được có quá 35 ký tự ký hiệu, bao gồm tất cả các ký hiệu mở rộng và ký tự số kiểm tra. Nếu không, sẽ có nguy cơ hệ số nhân thông tin có thể trở nên quá lớn trong trường hợp phân phối liên tổ chức.

Nhãn mã vạch là lựa chọn khả thi và hiệu quả cho doanh nghiệp để cải thiện năng suất và giảm chi phí… đây là một cách khác để nói rằng bạn có thể tiết kiệm thời gian và tiền bạc. Sau đây là một số cách bạn có thể sử dụng mã vạch để đạt được các mục tiêu đó:

Hãy bắt đầu với tiền bạc sử dụng mã vạch không tốn kém và thiết thực. Bạn thậm chí có thể tìm thấy các trình tạo mã vạch miễn phí trực tuyến. Ngoài yếu tố thời gian ban đầu được bao gồm trong quá trình thiết lập mã vạch, bạn sẽ biết rằng việc sử dụng mã vạch thực sự tiết kiệm tiền khi so sánh với các nhãn một lần. Chúng có thể được tùy chỉnh một cách tiết kiệm với nhiều loại hoàn thiện và vật liệu khác nhau.

Chi phí cho lỗi của con người có thể là một sự khó chịu hoặc khủng khiếp. Ví dụ, lỗi của con người trong việc sao chép thông tin cho mục đích y tế có thể là một thảm kịch. Mặt khác, kiểm kê chính xác có thể giúp bạn tiết kiệm tiền bằng cách giảm lượng hàng tồn kho quá mức để tính đến lỗi của con người đó. Lỗi của con người trong nhập dữ liệu có lẽ là lỗi tốn kém nhất đối với các doanh nghiệp. Giảm chi phí đó bằng nhãn mã vạch.

Tìm hiểu về Mã vạch rất dễ dàng và chỉ mất vài phút để học cách sử dụng máy quét cầm tay so với nhiều giờ để tìm hiểu về hàng tồn kho của công ty. Kiến thức đó không cần thiết khi sử dụng mã vạch. Do đó, bạn tiết kiệm được rất nhiều thời gian và chi phí đào tạo nhân viên.

Công nghệ mã vạch rất linh hoạt và dễ thích ứng. Bạn có thể gắn mã vạch vào bất kỳ bề mặt nào, giúp đơn giản hóa hoàn toàn không chỉ hàng tồn kho mà còn cả thiết bị văn phòng, lô hàng đi và hàng tồn kho đến.

Bạn có thể sử dụng một mã vạch cho cả thông tin hàng tồn kho và giá cả, do đó nhiệm vụ hạch toán hàng tồn kho và chi phí trở nên đơn giản hơn. Với mã vạch, bạn có thể nhanh chóng có được thông tin về cả hai tiêu chí. Ngoài ra, bạn có thể tùy chỉnh mã vạch để bao gồm bất kỳ thông tin nào khác mà bạn muốn xem.

Dữ liệu thu được thông qua mã vạch có sẵn trong nháy mắt. Vì thông tin được quét trực tiếp vào máy tính trung tâm của bạn nên thông tin sẽ sẵn sàng gần như ngay lập tức. Quá trình xử lý nhanh chóng này đảm bảo rằng thời gian sẽ không bị lãng phí vào việc nhập hoặc truy xuất dữ liệu.

Khi bạn nhận được thông tin ngay lập tức về hàng tồn kho, chi phí và dữ liệu khác, bạn có thể đưa ra quyết định kinh doanh tốt hơn. Không còn phải chờ đợi để tính toán số lượng với công nghệ mã vạch trong tầm tay bạn.

Tùy thuộc vào ứng dụng, thời gian tiết kiệm có thể rất đáng kể. Thường thì những ví dụ ấn tượng nhất liên quan đến công việc “yêu thích” là kiểm kê hàng tồn kho. Một khách hàng cần một đội gồm 25 nhân viên làm việc trong một tuần để kiểm kê hàng tồn kho sáu tháng hàng năm của mình. Khi chuyển sang mã vạch, anh ấy đã giảm đội ngũ kiểm kê xuống còn bốn nhân viên và thời gian kiểm kê xuống còn tổng cộng khoảng năm giờ.

Ngay cả trong các hoạt động hàng ngày thông thường, thời gian tiết kiệm được khi sử dụng mã vạch cũng nhanh chóng tăng lên để cải thiện năng suất. Khi so sánh biên soạn thông tin viết tay về hàng hóa xuất kho với cùng một hàng hóa được đóng dấu mã vạch, bạn có thể thấy sự cải thiện đáng kể về thời gian, chi phí và năng suất. Trong bất kỳ doanh nghiệp nào, khả năng tiết kiệm thời gian và tiền bạc này là một điểm cộng.

In mã vạch là phương pháp công nghệ được nhiều công ty trên thế giới sử dụng để vận chuyển sản phẩm, kiểm soát và cải thiện hàng tồn kho cũng như dễ dàng quản lý dữ liệu. Công nghệ mã vạch thân thiện với người dùng. Bất cứ thứ gì bạn có thể sử dụng để dễ dàng vận chuyển sản phẩm, kiểm soát hoặc cải thiện hàng tồn kho và giúp quản lý dữ liệu dễ dàng hơn đều là bạn của doanh nghiệp bạn.

|

|

Nhãn mã vạch và thu hồi sản phẩm

Điều đặc biệt quan trọng là có thể theo dõi sản phẩm từ nhà cung cấp đến cửa hàng trong trường hợp cần thu hồi. Trước đây, đã có nhiều trường hợp thu hồi sản phẩm trong các tình huống khủng hoảng mà rõ ràng là cần phải triển khai các quy trình theo dõi và trả lại liên công ty có mục tiêu hơn.

Nhãn mã vạch được sử dụng cho các hành động thu hồi nhằm nhanh chóng tìm ra sản phẩm lỗi để có thể loại bỏ chúng khỏi lưu thông, do đó ngăn chặn việc sử dụng chúng và hạn chế mọi thiệt hại có thể xảy ra. Điều này cho phép các nhà sản xuất quản lý việc thu hồi sản phẩm hiệu quả hơn. Đặc biệt, nhãn mã vạch mang lại những lợi thế sau khi thu hồi sản phẩm:

- Các nhà sản xuất có thể truy cập thông tin về vị trí cụ thể của sản phẩm dọc theo chuỗi cung ứng đến điểm bán hàng.

- Họ có thể loại bỏ sản phẩm hoặc phạm vi sản phẩm có vấn đề một cách có chọn lọc bất kể sản phẩm đó ở đâu vào một thời điểm cụ thể.

- Nhãn mã vạch bảo vệ người tiêu dùng bằng cách đảm bảo rằng họ không sở hữu sản phẩm lỗi.

- Nhãn mã vạch giúp giảm thiểu tình trạng mất uy tín do sản phẩm bị lỗi.

|

|

Chuyển đổi công việc kinh doanh

Nếu bạn tra cứu thông tin này trực tuyến, bạn sẽ thấy sự thật ở khắp mọi nơi: Tỷ lệ lỗi thông thường khi nhập dữ liệu của con người là 1 lỗi trên 300 ký tự gõ phím. Máy quét mã vạch chính xác hơn nhiều; tỷ lệ lỗi có thể nhỏ như 1 lỗi trên 36 nghìn tỷ ký tự tùy thuộc vào loại mã vạch được sử dụng.

Lỗi nhập dữ liệu và hành chính có thể là nguồn gây ra chi phí đáng kể và các vấn đề liên quan. Chi phí vận chuyển phát sinh, khách hàng không hài lòng và thời gian dành để theo dõi các vấn đề chỉ là một vài ví dụ về các vấn đề có thể làm hao hụt ngân sách của bạn. Trong một số trường hợp, lỗi hành chính có thể có tác động nghiêm trọng hơn nhiều, hãy xem xét tầm quan trọng của độ chính xác trong các ứng dụng dược phẩm hoặc ngân hàng máu.

Ngoài ra, bạn có thể sử dụng mã vạch như một công cụ hiệu quả để giải quyết các vấn đề hoặc sự cố cụ thể, cục bộ tích hợp vào hệ thống thông tin trên toàn tổ chức. Khi được áp dụng với sự cân nhắc và lập kế hoạch, mã vạch có thể tiết kiệm thời gian và giảm lỗi, dẫn đến giảm chi phí.

Cuối cùng, các cơ quan quản lý hoặc khách hàng của bạn có thể áp đặt các yêu cầu dán nhãn mà bạn phải đáp ứng. Mặc dù những yêu cầu này có thể là một phần cần thiết trong hoạt động kinh doanh, nhưng bạn có thể tiết kiệm thời gian và tiền bạc bằng cách sử dụng mã vạch trong hoạt động của riêng mình. Ví dụ: bạn có thể thu thập thông tin về danh mục vận chuyển nhanh chóng và chính xác bằng cách quét nhãn mã vạch mà bạn đã in để làm hài lòng khách hàng.

Cuộc tranh luận về nhãn in mã vạch

Bạn có thể đã đến cuộc tranh luận khi bạn cân nhắc giá trị giữa việc sử dụng nhãn in sẵn từ nguồn của bên thứ ba so với việc in theo yêu cầu bằng hệ thống mã vạch của riêng họ. Nhãn in sẵn hữu ích khi ứng dụng của bạn chỉ yêu cầu một vài nhãn giống hệt nhau, thường có nhiều màu sắc hoặc đồ họa. Tuy nhiên, các công ty bắt đầu bằng nhãn in sẵn nhanh chóng phát hiện ra những hạn chế của chúng.

Giải pháp rất đơn giản: Bên cạnh tính linh hoạt bị hạn chế, việc sử dụng nhãn in sẵn ngăn các công ty đưa dữ liệu biến đổi vào nhãn của họ, do đó làm giảm cơ sở thông tin của họ. Hầu hết các công ty thấy rằng cam kết về mã vạch theo yêu cầu và nội bộ là xứng đáng với khoản đầu tư ban đầu vì giá trị gia tăng từ việc in thông tin tùy chỉnh trên mỗi nhãn.

Máy in nhiệt cung cấp giải pháp tốt nhất để in mã vạch, khi so sánh với máy in laser hoặc máy in phun. Máy in nhiệt cung cấp chi phí sở hữu thấp hơn và in chính xác theo yêu cầu một lần thực sự để dễ dàng quét. Với nhãn mã vạch là một phần không thể thiếu của bất kỳ hệ thống nào, bạn muốn đảm bảo rằng nhãn được in rõ ràng mà không bị nhòe để đảm bảo ngay cả máy quét đơn giản nhất cũng có thể đọc tốt.

Nhãn nhiệt trực tiếp

Rất đơn giản: một loại sử dụng ruy băng và nhiệt để in, loại còn lại sử dụng lớp phủ và nhiệt. Đọc thêm về sự khác biệt giữa in nhãn nhiệt trực tiếp và in nhãn nhiệt chuyển nhiệt và cách chọn phương pháp phù hợp cho ứng dụng của bạn.

In nhiệt trực tiếp hoạt động như thế nào giải thích đơn giản:

Phương pháp này sử dụng đầu in được làm nóng để tạo ra phản ứng hóa học bên trong chính nhãn. Phản ứng này tạo ra hình ảnh có thể quét được khi in. Phương tiện duy nhất đi qua máy in là giấy nhãn dính có thể in. Thành phần hóa học của giấy nhãn và đầu in nhiệt là tất cả những gì cần thiết.

|

Cách thức hoạt động của in chuyển nhiệt giải thích đơn giản:

Phương pháp in này sử dụng đầu in nóng làm tan chảy ruy băng sáp trên mặt giấy trắng của nhãn có thể in. Cần có giấy hoặc phim và ruy băng. Loại giấy và ruy băng sẽ tùy thuộc vào ứng dụng. Kết quả của phương pháp này là bản in có thể quét được chất lượng cao, bền lâu.

|

Thành phần hệ thống in tem mã vạch, tem barcode là gì?

Tất cả các hệ thống in nhãn đều bao gồm 3 thành phần cốt lõi:

- Máy in mã vạch: Đây là khoản đầu tư lớn của bạn vào dự án này, vì một đơn vị có các tính năng phù hợp là rất quan trọng đối với việc in mã vạch. Các tùy chọn của bạn phụ thuộc vào lượng in bạn cần thực hiện và bạn cần di động hay cố định tại vị trí của mình. Các tùy chọn như giao diện, máy cắt, máy lột và phông chữ nhúng đều hoạt động để đảm bảo cấu hình tốt nhất cho ứng dụng của bạn.

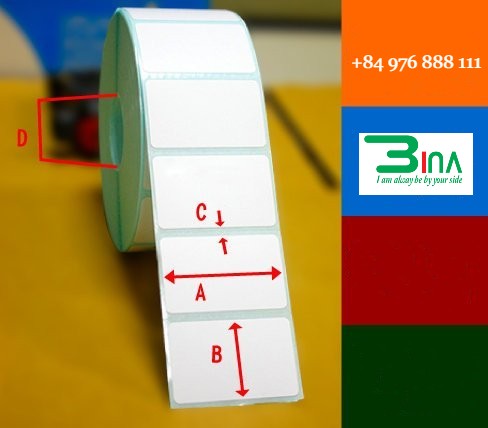

- Nhãn và ruy băng: Tiêu chí duy nhất liên quan ở đây là đảm bảo nhãn và ruy băng của bạn phù hợp với kiểu máy in của bạn để đảm bảo chất lượng in tốt nhất với nỗ lực tối thiểu.

- Phần mềm mã vạch: Cuối cùng, bạn cần một cách để cho máy in biết cách sử dụng ruy băng và nhãn để tạo mã vạch của mình. Phần mềm thiết kế nhãn có nhiều loại, từ máy chủ in cực kỳ đơn giản đến máy chủ in hoàn toàn tự động lấy thông tin từ cơ sở dữ liệu.

Đánh giá

Chưa có đánh giá nào.