Mô tả

Hạt nhựa TPE hay hạt nhựa TPR chất đàn hồi nhiệt dẻo là gì?

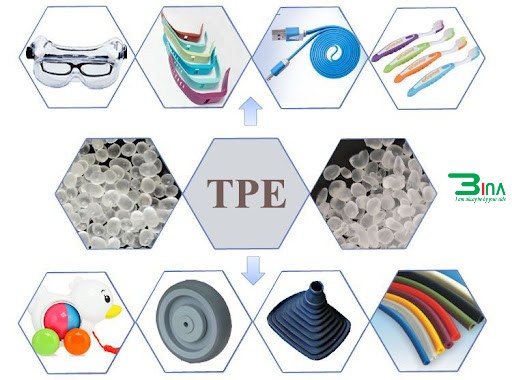

Chất đàn hồi nhiệt dẻo hay TPE là vật liệu mềm dẻo và giống cao su, xử lý như nhựa. TPE là chất đàn hồi nhiệt dẻo thực sự, không cần lưu hóa hoặc đóng rắn. Chất đàn hồi nhiệt dẻo được xử lý bằng nhiều thiết bị sản xuất nhựa khác nhau như ép phun, đùn và thổi khuôn. TPE có thể được sử dụng trong quá trình xử lý nâng cao như ép khuôn và đúc hai lần, và cũng có thể trải qua các hoạt động thứ cấp như hàn và liên kết với nhiều vật liệu khác nhau. Chất đàn hồi nhiệt dẻo cung cấp tính linh hoạt trong thiết kế bộ phận và liên kết dễ dàng với các chất nền nhiệt dẻo khác.

|

|

|

TPE – Nhựa đàn hồi nhiệt dẻo là một công cụ không thể thiếu được sử dụng bởi các nhà chế biến, nhà phát triển sản phẩm và nhà thiết kế. Chúng kết hợp các đặc tính xử lý động của nhựa nhiệt dẻo với độ mềm và độ linh hoạt của nhựa đàn hồi.

◆Tìm hiểu thêm:

- https://hadupack.com/san-pham/hat-nhua-pp/

- https://hadupack.com/san-pham/hat-nhua-pla/

- https://hadupack.com/san-pham/hat-nhua-pbt/

Các loại nhựa TPE khác nhau:

Các loại TPE khác nhau và các tùy chọn sửa đổi của chúng cung cấp cơ sở cho nhiều đặc tính vật liệu, do đó cho phép xử lý hiệu quả về mặt chi phí trong các ứng dụng cho các ngành công nghiệp đa dạng nhất.

TPE góp phần nâng cao sản phẩm và tạo sự khác biệt cho sản phẩm. Ngoài ra, chúng đảm nhiệm nhiều chức năng kỹ thuật mà từ trước đến nay vẫn dành riêng cho nhựa đàn hồi. Sử dụng TPE không chỉ làm tăng lợi ích của sản phẩm mà còn mang lại lợi thế kinh tế cho các nhà chế biến.

Quá trình xử lý và hành vi của vật liệu TPE phân loại chúng thành một nhóm vật liệu giữa nhựa nhiệt dẻo và nhựa đàn hồi. Chúng tạo thành một lớp vật liệu độc lập.

Về cơ bản, có sự phân biệt giữa TPE do lò phản ứng tạo ra (ví dụ: TPA, TPU và TPC) và hợp chất TPE (ví dụ: TPS và TPV). Các đặc tính của TPE do lò phản ứng tạo ra được thực hiện trong một loại polymer. Các đặc tính của hỗn hợp TPE là kết quả của việc trộn các loại polymer khác nhau để tạo thành cái gọi là hợp chất.

|

TPE được xử lý như thế nào?

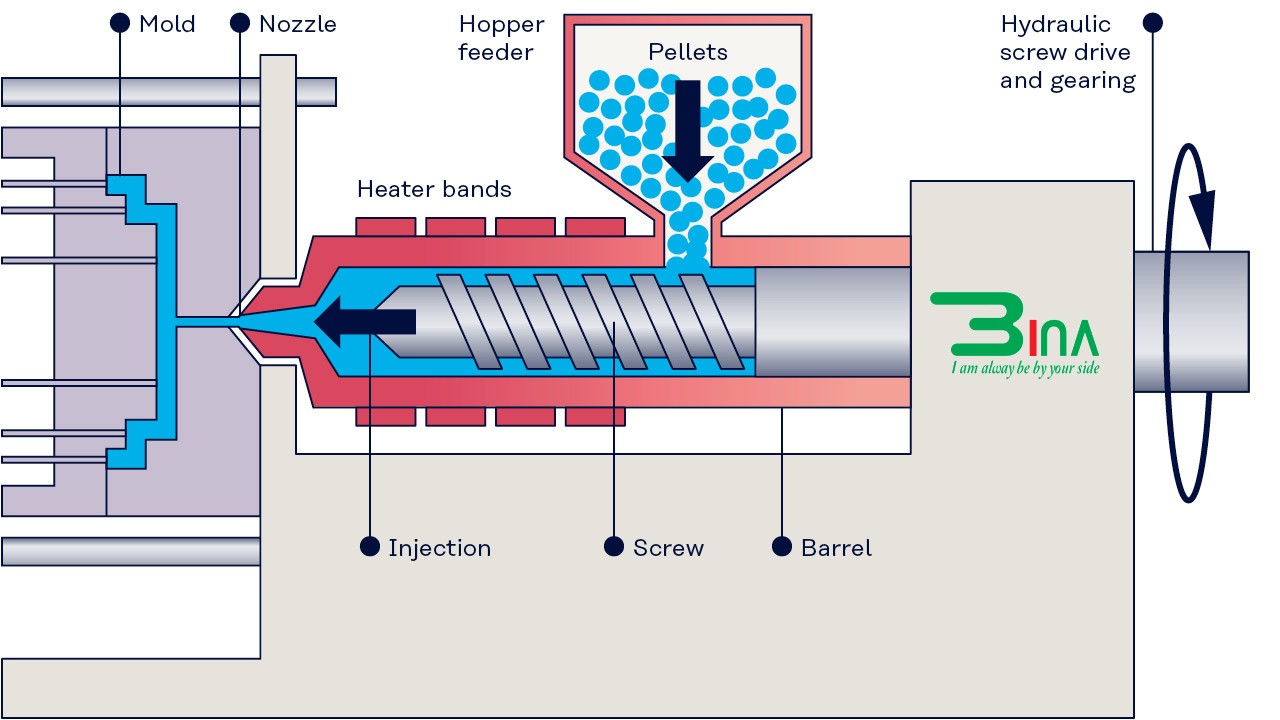

Giống như nhựa nhiệt dẻo, TPE được nung nóng để xử lý bằng phương pháp đúc phun hoặc đùn. Khi chúng thể hiện lại các đặc tính đàn hồi ban đầu sau khi làm mát, chúng có thể tái chế như nhựa nhiệt dẻo. Trái ngược với TPE, chất đàn hồi không thể được xử lý bằng cách nấu chảy; chúng được liên kết chéo về mặt hóa học và không thể tái chế.

- Những lý lẽ mạnh nhất ủng hộ việc sử dụng TPE

- Xử lý nhựa nhiệt dẻo dễ dàng

- Thời gian chu kỳ ngắn

- Tiêu thụ năng lượng thấp

- Xử lý nhiều thành phần và do đó giảm chi phí lắp ráp

- Kết hợp các vật liệu khác nhau (ví dụ: vật liệu composite cứng-mềm)

- 100% có thể tái chế trong quá trình xử lý

- Cửa sổ xử lý rộng

- Nhiều tùy chọn màu sắc, bao gồm hiệu ứng màu sắc để thiết kế linh hoạt hơn

- Nhiều ứng dụng khả thi từ lĩnh vực ô tô đến ngành dược phẩm.

|

Phân loại hạt nhựa TPR

Polyme được phân loại thành bốn nhóm: nhiệt dẻo, nhiệt rắn, chất đàn hồi và chất đàn hồi nhiệt dẻo (TPE).

- Nhiệt dẻo bao gồm các chuỗi polyme và có độ rối cao. Chúng được giữ lại với nhau thông qua các tương tác giữa các phân tử như lực van der Waals. Các hiệu ứng nhiệt và lực cắt cho phép chúng được xử lý bằng phương pháp đúc phun. Khi nguội, vật liệu sẽ đông cứng trở lại. Vì quá trình này hoàn toàn là vật lý nên có thể lặp lại bất kỳ lúc nào (ví dụ: polypropylen).

- Chất nhiệt rắn như nhựa epoxy là polyme được liên kết chéo chặt chẽ thông qua các liên kết hóa học và không tan chảy. Chúng duy trì cấu trúc liên kết chéo của mình ngay cả ở nhiệt độ cao và có đặc điểm là độ bền và độ cứng cao. Khi chịu ứng suất, chúng dễ bị gãy giòn (ví dụ: nhựa epoxy).

Chất đàn hồi, thường được gọi là cao su, là polyme liên kết chéo về mặt hóa học. Chúng ít liên kết chéo hơn đáng kể so với chất nhiệt rắn, để lại các vùng đàn hồi lớn hơn giữa các liên kết chéo riêng lẻ. Các vùng này rất quan trọng đối với các đặc tính đàn hồi của chúng. Chất đàn hồi không thể bị nấu chảy trở lại. Sau khi liên kết chéo, chúng sẽ duy trì hình dạng của chúng. Ví dụ về chất đàn hồi là cao su thiên nhiên hoặc cao su tổng hợp như EPDM và NBR.

Về cơ bản, chất đàn hồi nhiệt dẻo có thể được chia thành hai loại: TPE do lò phản ứng tạo ra (ví dụ: TPA, TPU và TPC) và hợp chất TPE (ví dụ: TPS hoặc TPV). Các đặc tính của TPE do lò phản ứng tạo ra được triển khai trong một loại polyme. Các đặc tính của hợp chất TPE là kết quả của việc trộn hai loại polyme để tạo thành cái gọi là hợp chất.

Đánh giá

Chưa có đánh giá nào.